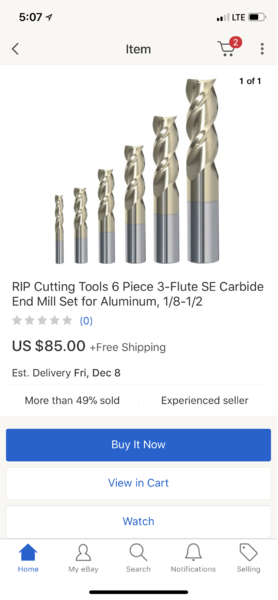

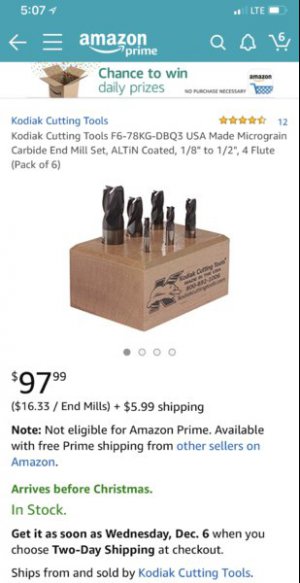

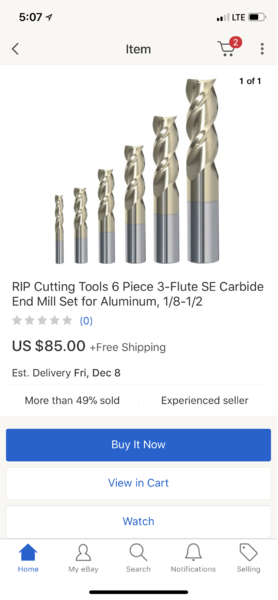

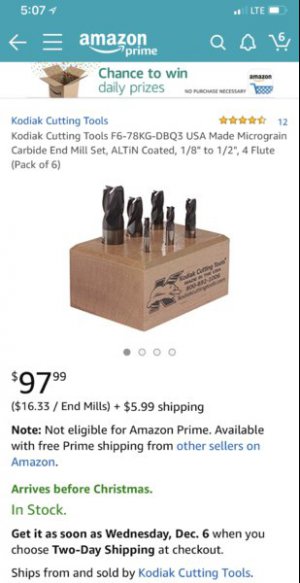

Hey guys, the PM-30MV that I ordered just shipped and will be to me on Monday, so I’m planning to purchase a couple sets of end mills and maybe a face mill. Here’s what I’ve found so far:

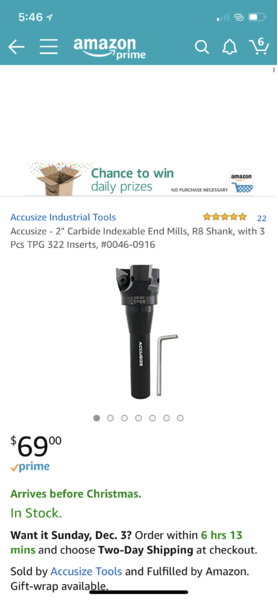

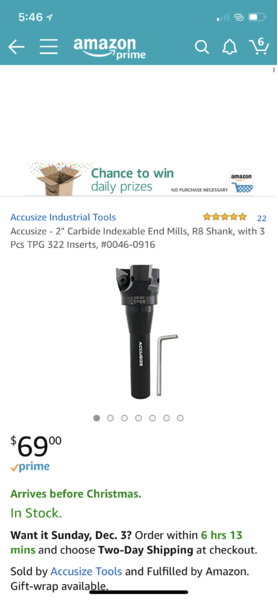

Anything wrong with these choices just starting out? I figured this would cover me for mild steel and aluminum for now. I’ve also got my eye on this face mill:

So I figured that would get me started, any thoughts? Comments? Better suggestions?

Thanks guys!

Anything wrong with these choices just starting out? I figured this would cover me for mild steel and aluminum for now. I’ve also got my eye on this face mill:

So I figured that would get me started, any thoughts? Comments? Better suggestions?

Thanks guys!