- Joined

- Sep 4, 2013

- Messages

- 113

I didn’t want to hijack someone else’s thread so started a new one. I’m no stranger to messing around with electric motors, but have more experience with 3ph, and dc, which is not helping here.

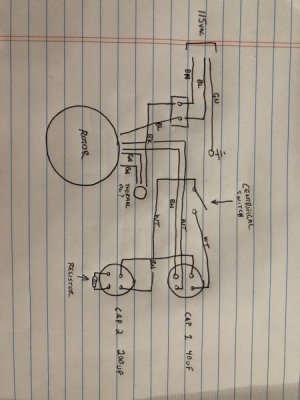

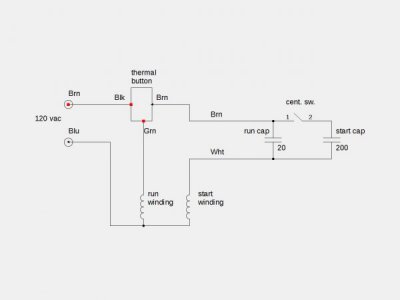

I acquired a nice unit out of a scrap bin, it’s a single phase, 1hp, hazardous location motor. A.L. Claret is the manufacturer (France). I have a need to run the motor opposite it’s current rotation. Done some reading the past couple nights and it’s sounds easy enough, reverse the polarity of the start winding. Problem is, there are two capacitors wired into this motor, along with some kind of sensor/switch in the bottom under the centrifugal switch (guessing thermal overload switch). So before I go swapping wires around and burning something up, I figured I’d get some opinions from you fine people.

I won’t need to change direction of the motor as it’s running a saw, so just need to permanently change direction.

Sent from my iPhone using Tapatalk

I acquired a nice unit out of a scrap bin, it’s a single phase, 1hp, hazardous location motor. A.L. Claret is the manufacturer (France). I have a need to run the motor opposite it’s current rotation. Done some reading the past couple nights and it’s sounds easy enough, reverse the polarity of the start winding. Problem is, there are two capacitors wired into this motor, along with some kind of sensor/switch in the bottom under the centrifugal switch (guessing thermal overload switch). So before I go swapping wires around and burning something up, I figured I’d get some opinions from you fine people.

I won’t need to change direction of the motor as it’s running a saw, so just need to permanently change direction.

Sent from my iPhone using Tapatalk