- Joined

- Oct 17, 2018

- Messages

- 922

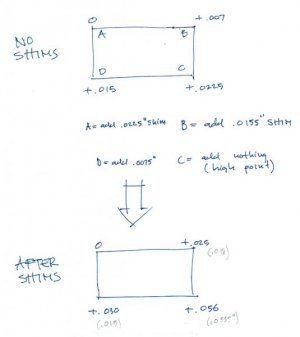

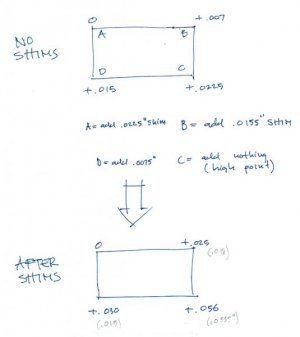

I'm trying to tram up my LMS 3990. Here are the indicator readings before and after:

I'm clearly doing something wrong because it's nowhere close! My thought was to bring the 3 lower points (A, B, D) to the same level as the highest point (C). I thought it made sense to do all 4 at once. I thought I was making all 4 points the same height.

I'm using the shims from LMS and torquing everything down the same with a torque wrench. The head up and down movement is locked. I check zero after making the measurements.

I'm clearly doing something wrong because it's nowhere close! My thought was to bring the 3 lower points (A, B, D) to the same level as the highest point (C). I thought it made sense to do all 4 at once. I thought I was making all 4 points the same height.

I'm using the shims from LMS and torquing everything down the same with a torque wrench. The head up and down movement is locked. I check zero after making the measurements.