Hi again,

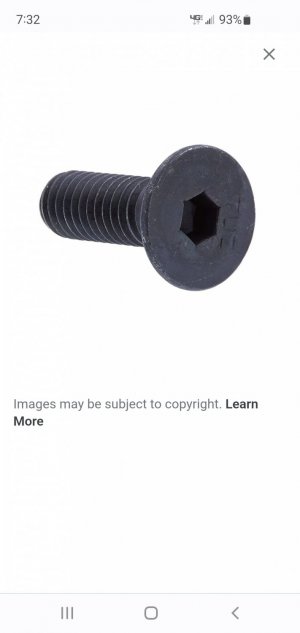

I have some bike sprockets I need attaching to an aluminium carrier with approx M3 x 6mm flat head steel rivets. I don't trust myself to do this without a rivet gun as the margin for error isn't huge.

See attached for example of what I mean.

Many thanks as always

I have some bike sprockets I need attaching to an aluminium carrier with approx M3 x 6mm flat head steel rivets. I don't trust myself to do this without a rivet gun as the margin for error isn't huge.

See attached for example of what I mean.

Many thanks as always