Hey y'all, I have a piece of cast iron tubing. It's 1/8" wall, 1.1/4" diameter, has a 3/8" wide x 1 1/2" long slot machined into it. I need to know the most efficient way to do a nice looking, heavy chamfer on the outside of the slot. The chamfer should extend to the bottom edge of the slot and the top of the slot will measure 1/2" wide when finished. Cosmetic appearance is a must. What's y'all's thoughts on this matter?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need to know best way to machine a chamfer READ

- Thread starter Mutt

- Start date

- Joined

- Aug 7, 2018

- Messages

- 668

Hi Mutt,

I would dig out my carbide wood router bits and select one suitable for the chamfer you want. Use it as though it was a HSS cutter but a little slower.

Go steady because you want to avoid the cutter chipping and leaving a score line.

I would dig out my carbide wood router bits and select one suitable for the chamfer you want. Use it as though it was a HSS cutter but a little slower.

Go steady because you want to avoid the cutter chipping and leaving a score line.

I'm looking for something like what would be equal to a 1º first cut, 2º second cut a 3º final cut. What I am not understanding is if the center line of the slot is vertical in my mill, will the entire slot get cut all in one pass, including the ends of the slot . 3/8" wide

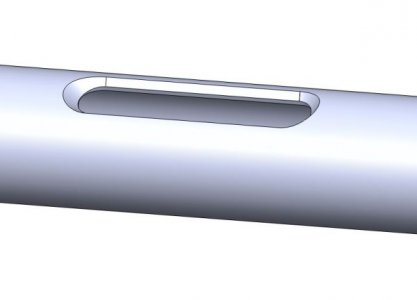

Here is the unaltered slot

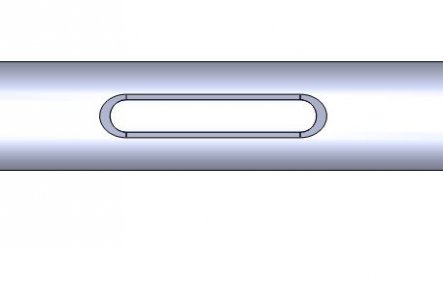

here is what I need to achieve

Here is the unaltered slot

here is what I need to achieve

- Joined

- Feb 8, 2014

- Messages

- 11,144

What I am not understanding is if the center line of the slot is vertical in my mill, will the entire slot get cut all in one pass, including the ends of the slot . 3/8" wide

It will if you use the correct cutter. But the included angle is about 53 degrees, which is not a standard cutter. Because you are cutting on an arc, the ends of the slot will be cut a bit deeper than the sides in a strictly straight cut at constant depth.

If you don't have a 5 (6?) axis CNC mill, a little hand work with a file(s) and some emery cloth will probably be required.

Isn't a 45º included a standard size ? I can live with that. So what would the resulting slot look like if you just machine it in a straight line using a router bit in the mill? The straight sides will be fine I know, but what happens to the 3/8" radius at each end of the slot?

- Joined

- Aug 7, 2018

- Messages

- 668

Hi Mutt, Guys,

That would depend upon whether you cut both sides of the slot at the same time ! Not advised !

I would use the whole of the depth of the cutter to do the ends and then each edge separately. That way you will also avoid climb milling.

If you are careful you won't have to do any blending in.

That would depend upon whether you cut both sides of the slot at the same time ! Not advised !

I would use the whole of the depth of the cutter to do the ends and then each edge separately. That way you will also avoid climb milling.

If you are careful you won't have to do any blending in.

- Joined

- Feb 8, 2014

- Messages

- 11,144

Yes, a 45° included angle is standard.

The chamfer will be a bit wider at the ends. It will cut about 0.046 deeper into the OD than on the sides. This is due to the height of the arc segment relative to the sides.

The chamfer will be a bit wider at the ends. It will cut about 0.046 deeper into the OD than on the sides. This is due to the height of the arc segment relative to the sides.

- Joined

- Feb 1, 2015

- Messages

- 9,578

- Joined

- Feb 1, 2015

- Messages

- 9,578

Note in the above post that the chamfer doesn't go to the bottom of the slot. You would need to go .047" deeper with the chamfer. If you do so it will be .564" wide at the top.