- Joined

- May 27, 2016

- Messages

- 3,469

Agreed! A track-hold is a fast and simpler method of grabbing the count for the peak value, and of course, by setting some thresholds, you can get the count of how many pulses had that value, for the histogram - which is what the display is.

You can use a fast A/D conversion, with many samples, to get what amounts to an oscilloscope display of the pulse and afterglow waveform of the scintillation. From that, get the peak value. Lots of computing.

I had thought that unless the shape and duration of the scintillation has informational value in helping determine the energy, I didn't see it as useful. BUT - I am reading, reading, reading. I feel like I am back in study days for exams. There is too much here that I know I just don't (yet) know.

GIven that I do not have any Windows computers at all, I have installed PyMCA, and I will probably roll my own electronics.

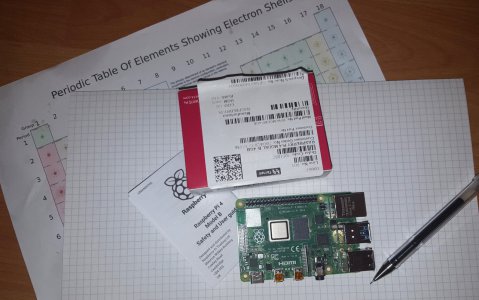

If I can make the outboard stuff USB/Bluetooth, then any platform can use it if the communication format is kept the same. I am very tempted to use a Raspberry Pi with a add-on hat board to work the scintillation hardware, and even that might allow any sensor type. It has the advantage that it comes with it's own little computer, but can just as easily be a USB/WiFi/BlueTooth link to a desktop PC or laptop, and OS agnostic so it can deliver to Windows computers OK.

You can use a fast A/D conversion, with many samples, to get what amounts to an oscilloscope display of the pulse and afterglow waveform of the scintillation. From that, get the peak value. Lots of computing.

I had thought that unless the shape and duration of the scintillation has informational value in helping determine the energy, I didn't see it as useful. BUT - I am reading, reading, reading. I feel like I am back in study days for exams. There is too much here that I know I just don't (yet) know.

GIven that I do not have any Windows computers at all, I have installed PyMCA, and I will probably roll my own electronics.

If I can make the outboard stuff USB/Bluetooth, then any platform can use it if the communication format is kept the same. I am very tempted to use a Raspberry Pi with a add-on hat board to work the scintillation hardware, and even that might allow any sensor type. It has the advantage that it comes with it's own little computer, but can just as easily be a USB/WiFi/BlueTooth link to a desktop PC or laptop, and OS agnostic so it can deliver to Windows computers OK.

Last edited: