- Joined

- May 27, 2016

- Messages

- 3,469

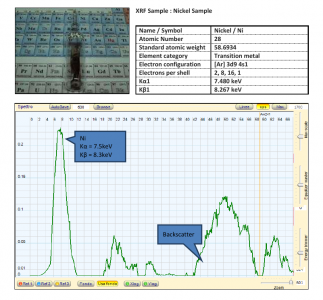

Addressing whether or not to use large area silicon photodiode sensors. The best of these have similar gain to PMT electron tube, but inherently have the noise floor all solid state semiconductors have. Revese biased avalanche diodes operating at or beyond breakdown along with current limiting, quenching and damping circuitry, have been around for a some time, wheras the large area diode types devoted to X-Ray and other detection are newer speciality products.Scintillators and PMTs aren't used in commercial EDX tools these days. Instead, they use large-area silicon detectors, basically high voltage diodes. As in the case of a scintillator/PMT, the pulse height is proportional to the x-ray photon energy. That, by the way, is what "EDX" stands for -- energy dispersive x-ray spectroscopy. There is another approach that uses a crystal as a kind of diffraction grating, where the grating is the crystal lattice itself. As the crystal is rotated the incident x-rays are diffracted at different angles toward a fixed detector. Very much like a visible-light monochromator. This type of system offers much higher resolution but, because it acquires one wavelength at a time, it is much slower. Also, you STILL need some kind of detector. This type of system is called a WDX, or wavelength-dispersive x-ray spectrometer. Our old WDX used an ionization detector, a lot like a Geiger tube -- but IIRC the active gas was either a mixture of methane or carbon monoxide (!).

Also check these links out: http://www.noah.org/science/x-ray/detector/ https://benkrasnow.blogspot.com/2012/11/large-area-detector-for-x-rays.html ; and you might be able to acquire some of the hardware here. I haven't gone so far as to check prices from the latter so it still could be out of the range of what hobbyists would be willing to pay.

I am used to going after the ultimate low noise floor short of cryogenics using pHEMT (PseudoMorphic High Electron Mobility Transistors) in microwave satellite kit. Getting the signal captured with a good signal-to-noise ratio is key. To this add the front-end noise of the gain system. The signal is amplified, and from then on, it is safe, because the noise is amplified as well. The signal-to-noise ratio becomes locked in, because any subsequent processing has to be grossly noisy before that noise can compete with the racket already amplified.

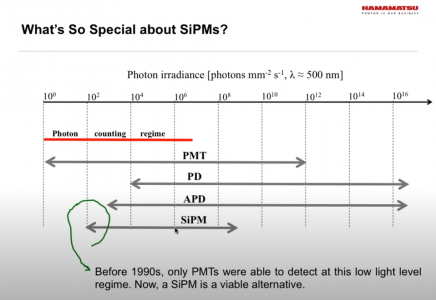

What drives my first choice is taken from a Hamamatsu webinar [1], promoting SiPM (Silicon Photomultiplier) is this chart.

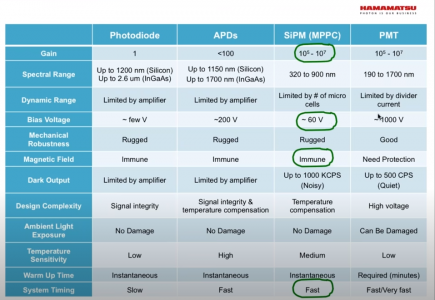

And a table

Notice the region 1 to 10000 covered well by the electron tubes. The noise limit for SiPM diodes is actually around 2000. In the table, the Hamamatsu propaganda stressed only the highlighted stuff in column 3. I put value on the dark output. I would not set the need for temperature compensation against high voltage.

Temperature compensation is a pain, and since the highest voltage I have ever dealt with in really high energy kit was 35kV, or in discharge kit, about 160kV, I don't think high voltage is such a disadvantage, especially since this kind is so high impedance, you can touch it, and it collapses. The last reason is much more prosaic. The tubes seem affordable, and at the level I would play, simple, and were used in an existing, albeit dated, design.

The system considered here is not the WDX wavelength dispersive method, which would be the conventional way of splitting wavelength components into spectrum - like a prism. This is the "other" sort, but the name escapes me. Would it be "Energy Transient Integral Dispersion" or something like that. Even so, I would live to know if the photons scattered from the metal could be deflected into a sensor array by some scintillator.

A basic question to ask is.. are the wavelengths coming back at the sensor X-Ray wavelengths? I have not yet checked the energies for the alloy metals yet. There is just too much to read in a short time. I am still at the somewhat skeptical stage, just thinking through the first recipe. For this to be something we attempt, it had better not cost more than about $200 + some fun project build time.

You did, after all, provide the first DIY link. That leads on to a lot of stuff, mostly in Italian!

If we can cook up something that almost any HM member can replicate, that does only one thing well, with minimum cost, that would be something to aim for. Right now, I am still all too aware of how much I don't know!

[1] Hamamatsu Silicon Photomultipliers Webinar

Last edited:

). This also drops the voltage necessary to bias the detector into its proportional-detector mode.

). This also drops the voltage necessary to bias the detector into its proportional-detector mode.