H

Hukshawn

Forum Guest

Register Today

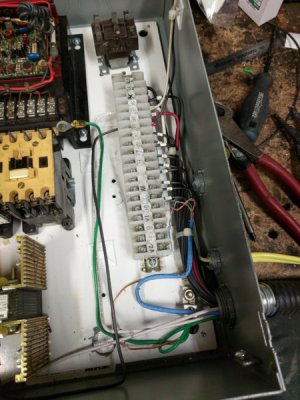

I had converted my lathe to a dc motor a little while ago and had various threads while i sorted out and gained knowledge.

it had been a hob-cobble. ive decided to set it all up properly and with push buttons.

ill chronicle that here.

it had been a hob-cobble. ive decided to set it all up properly and with push buttons.

ill chronicle that here.