Howdy,

I just purchased a Craftsman 101.07403 lathe at a machinist's estate sale with a variety of tooling, but have only run a lathe once in my life (in school for Engineering) so I'm glad I found this site, it's been a great source of info so far!

Here's my machine, I also have a nice 50s vintage Atlas drill press to match.

Current goals are to get it cleaned up and running as the new year starts, but I need a motor. I know it's a 56 frame 1750rpm one, but does anybody have any recommendations? I see some Century ones on Amazon for reasonable prices. I also got a SquareD reversing switch along with the lathe, so I'll have to figure out how to wire that up.

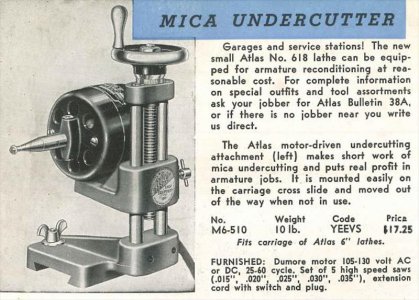

Have no need for the Mica undercutter, but it's a neat little device, works great too!

I just purchased a Craftsman 101.07403 lathe at a machinist's estate sale with a variety of tooling, but have only run a lathe once in my life (in school for Engineering) so I'm glad I found this site, it's been a great source of info so far!

Here's my machine, I also have a nice 50s vintage Atlas drill press to match.

Current goals are to get it cleaned up and running as the new year starts, but I need a motor. I know it's a 56 frame 1750rpm one, but does anybody have any recommendations? I see some Century ones on Amazon for reasonable prices. I also got a SquareD reversing switch along with the lathe, so I'll have to figure out how to wire that up.

Have no need for the Mica undercutter, but it's a neat little device, works great too!