- Joined

- Mar 21, 2013

- Messages

- 4,063

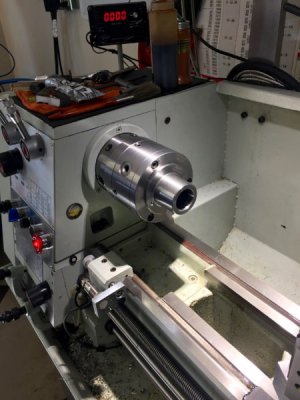

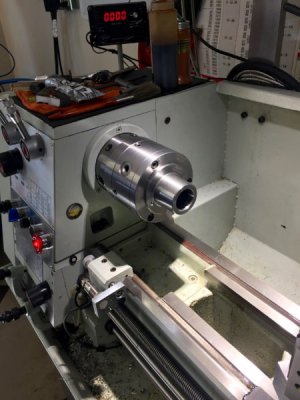

A very generous friend took pity on me and bought me a TMX set-tru 5c collet chuck, and a set of 35 collets (1/16" spacing?). To say that I'm grateful doesn't come close, and I'm a bit embarrassed by all this, but I'll get over it.

The chuck is a TMX. I'd never heard of them, but when the chuck arrived it is stamped 'Made in Poland' and looks suspiciously like a Bison. My friend says they are identical, so maybe they come from the same factory?

The collet set is from Precision Matthews. I want to be able to grab pretty much any diameter, and this should do the trick. I read somewhere that there are sets with 1/64" spacing, but that they are very costly. Anyway...

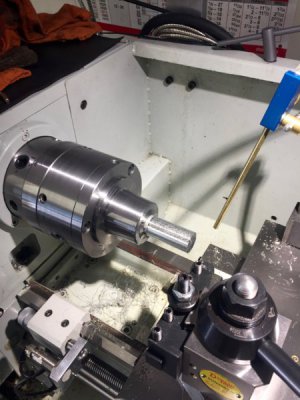

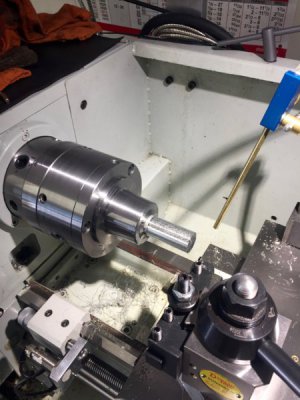

I mounted the backing plate and checked TIR. I was reading about .0005", so marked the current indexing and gave it a 'fuzz pass'. Checked again and I can't measure the runout. Cool. Mounted the chuck to the backing plate, put a dti on the shoulder inside the nose and adjusted the chuck. Then I put a 0.5 gauge pin in the 1/2" collet and put that in the chuck. Saw about .0005" TIR on the outside of the gauge pin about 1" from the nose of the chuck. Proceeded to chuck up a piece of 1" 7075 and made a couple of cleanup passes. Pulled the piece out and measured a diameter variation of .0002" across 2.7" of length.

I've never owned or used a 5c collet chuck, so did I do this right? If so, I'll attribute the .0002" of taper to part flex and leave well enough alone.

Some pics:

It's such a cute little chuck, compared to my 8.5" PBA.

The chuck is a TMX. I'd never heard of them, but when the chuck arrived it is stamped 'Made in Poland' and looks suspiciously like a Bison. My friend says they are identical, so maybe they come from the same factory?

The collet set is from Precision Matthews. I want to be able to grab pretty much any diameter, and this should do the trick. I read somewhere that there are sets with 1/64" spacing, but that they are very costly. Anyway...

I mounted the backing plate and checked TIR. I was reading about .0005", so marked the current indexing and gave it a 'fuzz pass'. Checked again and I can't measure the runout. Cool. Mounted the chuck to the backing plate, put a dti on the shoulder inside the nose and adjusted the chuck. Then I put a 0.5 gauge pin in the 1/2" collet and put that in the chuck. Saw about .0005" TIR on the outside of the gauge pin about 1" from the nose of the chuck. Proceeded to chuck up a piece of 1" 7075 and made a couple of cleanup passes. Pulled the piece out and measured a diameter variation of .0002" across 2.7" of length.

I've never owned or used a 5c collet chuck, so did I do this right? If so, I'll attribute the .0002" of taper to part flex and leave well enough alone.

Some pics:

It's such a cute little chuck, compared to my 8.5" PBA.