- Joined

- Feb 8, 2014

- Messages

- 11,144

I have a project coming up that is going to require a ball turner. I could buy one, but what fun is that.

The insperation for this design come from http://www.hobby-machinist.com/threads/just-finished-my-lathe-radius-and-ball-turner.61362/

I'm making it a bit different, but the same principal.

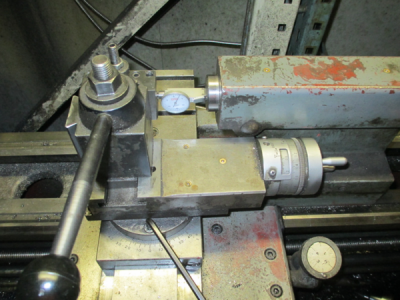

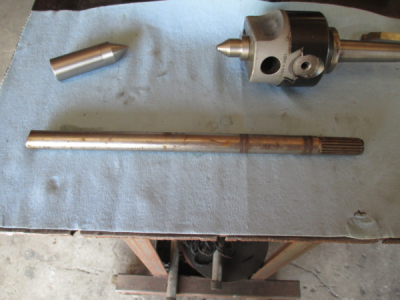

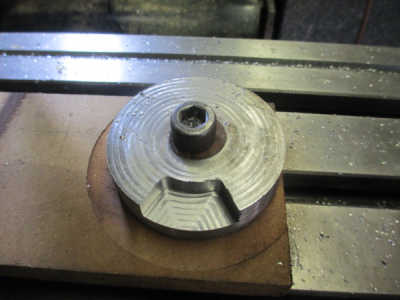

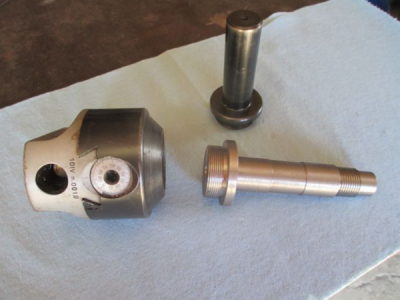

So head for the rack to find some material. Found a piece of 2x2 6061, and a piece of 1 15/16 rusty old hydraulic cylinder shaft. Not sure what it is, but has a light hard chrome surface and machines very nice. The chips come off like 41 something. And my Criterion 3 inch boring head. Ordered a few other bits & pieces from McMaster that aren't here yet.

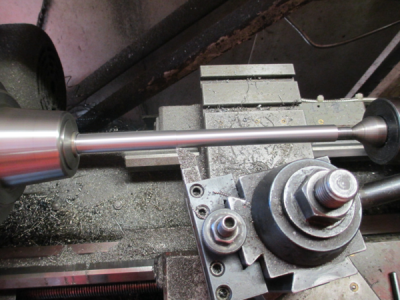

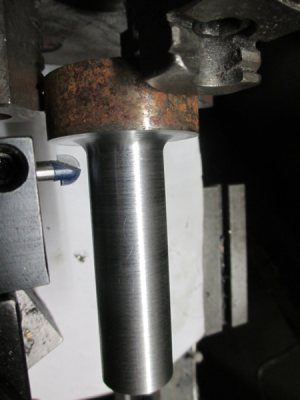

So first make the arbor. I left the bearing journals 0.010 over so I can fit later to the reamed hole in the aluminum mount. The new DRO on my lathe is great for laying out the steps on the arbor. Should have installed one a long time ago.

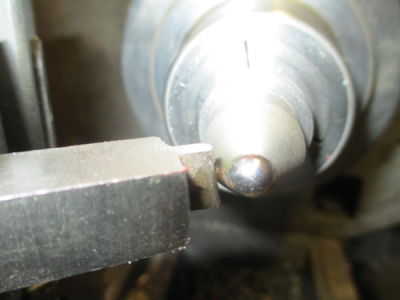

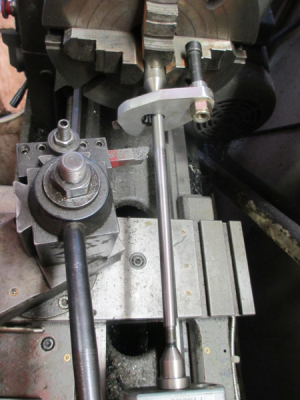

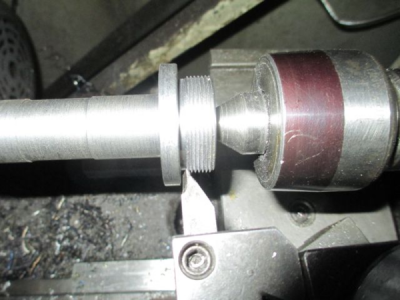

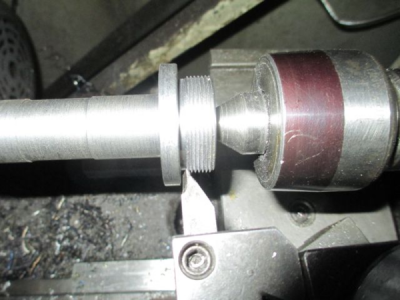

For those of you who have never done this before, here is my method of threading to a shoulder.

Turn the tool upside down and run the lathe backwards. That way you are feeding away from the shoulder.

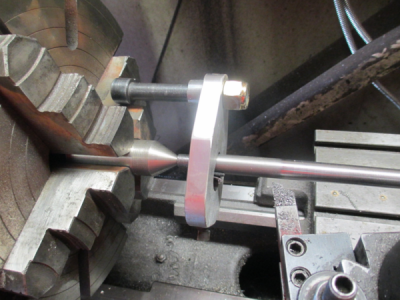

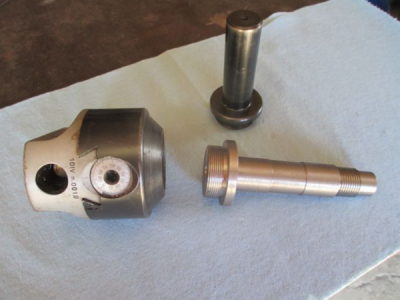

And another view

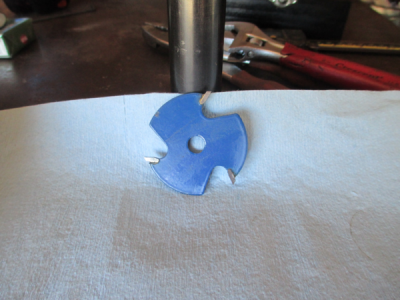

If will be a few days before I can update, waiting for my new dovetail cutter to cut the dovetail for the tool holder. I hope aluminum will work for a quick change, hope it's not too soft. I'll find out. If it doesn't work, I get some 4140 and make another.

Stay tuned for more......

The insperation for this design come from http://www.hobby-machinist.com/threads/just-finished-my-lathe-radius-and-ball-turner.61362/

I'm making it a bit different, but the same principal.

So head for the rack to find some material. Found a piece of 2x2 6061, and a piece of 1 15/16 rusty old hydraulic cylinder shaft. Not sure what it is, but has a light hard chrome surface and machines very nice. The chips come off like 41 something. And my Criterion 3 inch boring head. Ordered a few other bits & pieces from McMaster that aren't here yet.

So first make the arbor. I left the bearing journals 0.010 over so I can fit later to the reamed hole in the aluminum mount. The new DRO on my lathe is great for laying out the steps on the arbor. Should have installed one a long time ago.

For those of you who have never done this before, here is my method of threading to a shoulder.

Turn the tool upside down and run the lathe backwards. That way you are feeding away from the shoulder.

And another view

If will be a few days before I can update, waiting for my new dovetail cutter to cut the dovetail for the tool holder. I hope aluminum will work for a quick change, hope it's not too soft. I'll find out. If it doesn't work, I get some 4140 and make another.

Stay tuned for more......