-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Cnc Build Full Enclosure And Auto Tool Changer

- Thread starter native34

- Start date

I'm still working out the details for the tool changer, so I don't have everything worked out yet. The first place I wanted to start was to get the pull stud tooling and spindle working before I start the tool changer. I have some ideas on what I think the tool changer will look like and how it will function but nothing carved in stone. I will keep you posted as I start getting to that point of my build. I do know it will incorporate the R8 spindle that ships with every machine of this type.

- Joined

- Jul 23, 2014

- Messages

- 347

Dude! You know how they say dog years are like 7 human years? You just did about 20 years worth of work on my timeline! I dang near ordered electronics three or four times now. That has only taken me 18 months...to almost do.

Are you going with steppers or servos, and what size? Counterbalance the z?

Are you going with steppers or servos, and what size? Counterbalance the z?

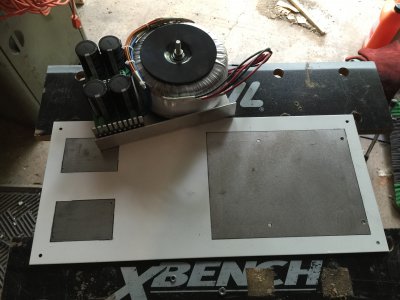

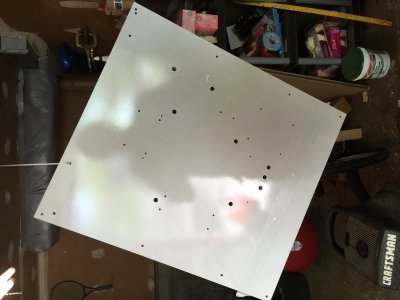

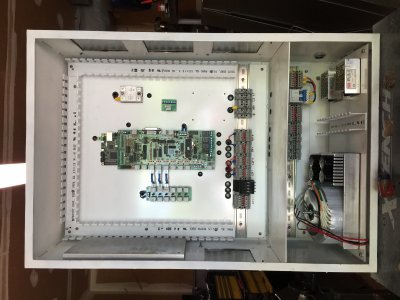

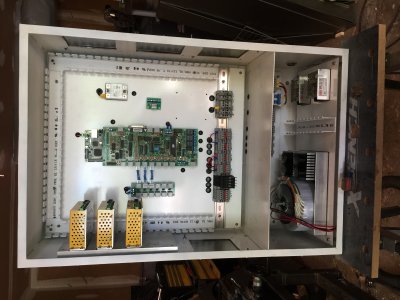

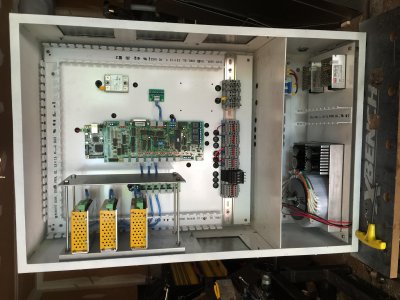

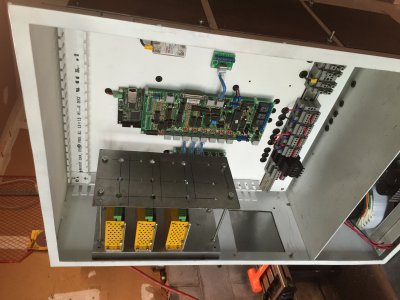

My mill is up and running, finally. I am having a slight problem with the outer profile of my parts coming out oversized. I went with Servos, 850oz KL34-170-72, C32 multifunctin board, Ethernet smooth stepper, various other boards. The drives i got from cnc4pc as well. they are DG4s8020 drives made by cncdrive.com.