- Joined

- Nov 11, 2014

- Messages

- 111

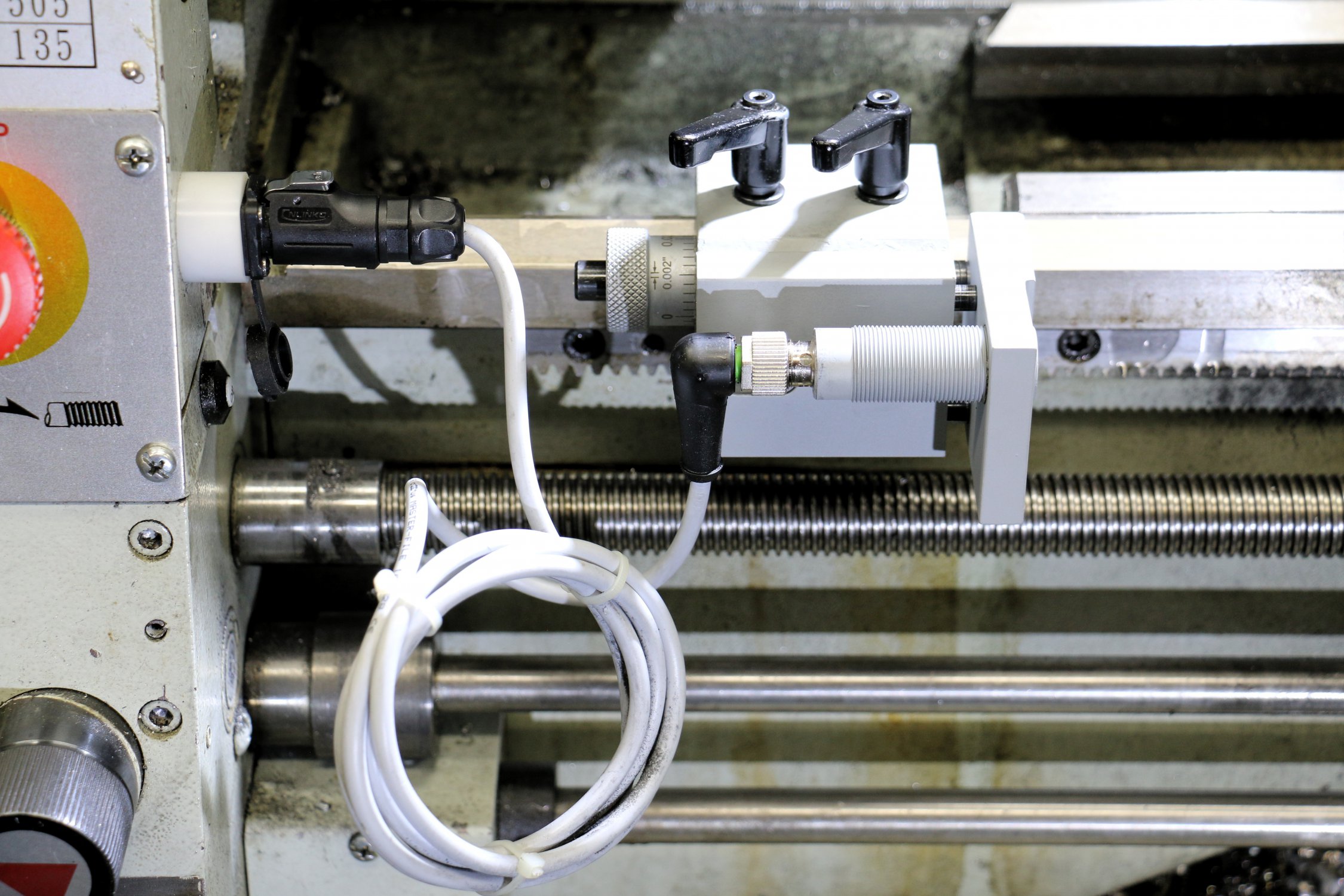

I wanted to install a threading proximity sensor on my PM 1340GT for a long time but procrastination being what it is I just got around to doing it. First, I wanted to use the existing micrometer stop and have the sensor easily removable for safe storage when not in use.

Second, since I have a VFD installed using the original lathe relays as outlined by Mark "mksj" I needed to find a way to integrate the sensor stop/start signal into the existing lathe setup.

First, the sensor micrometer stop design.

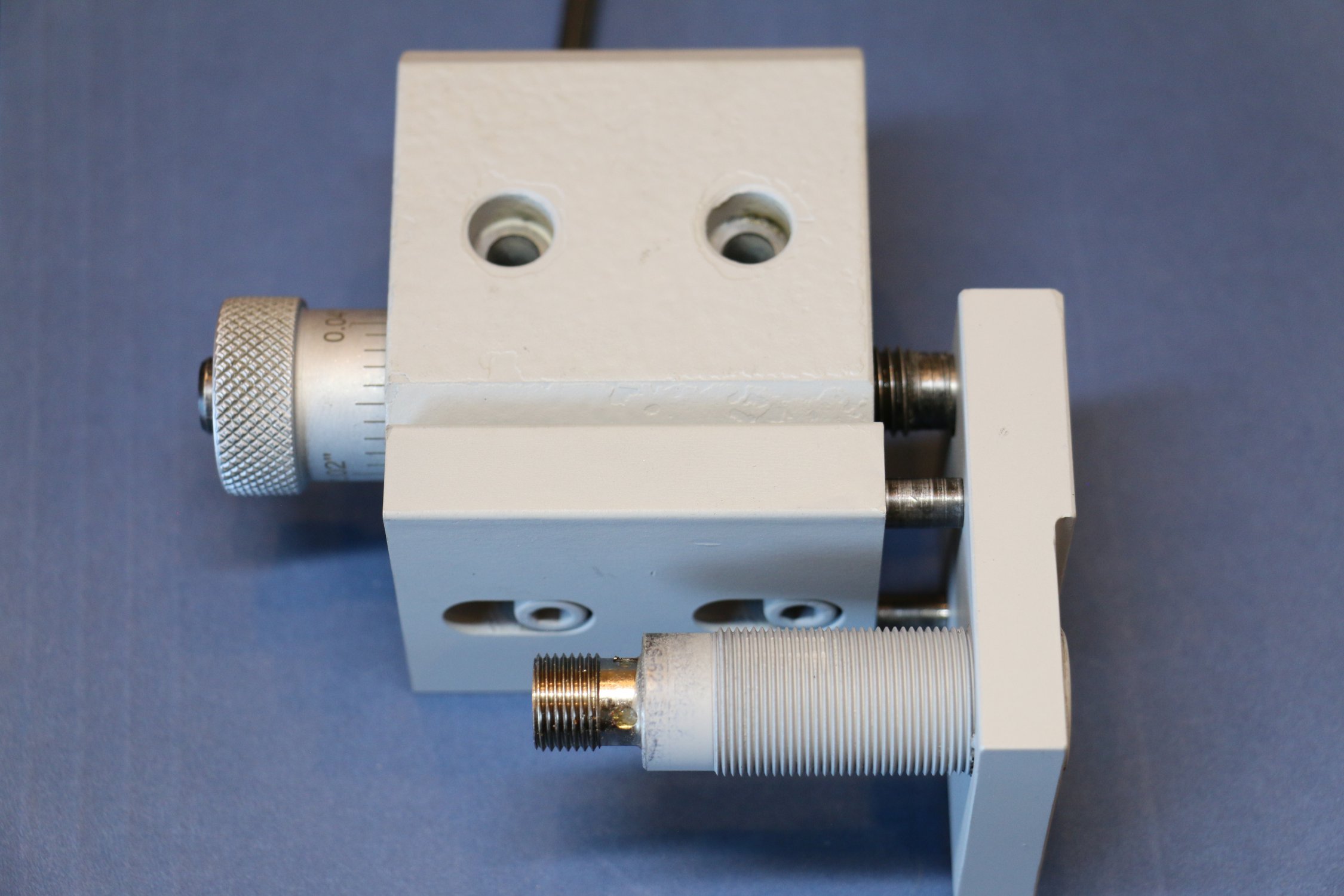

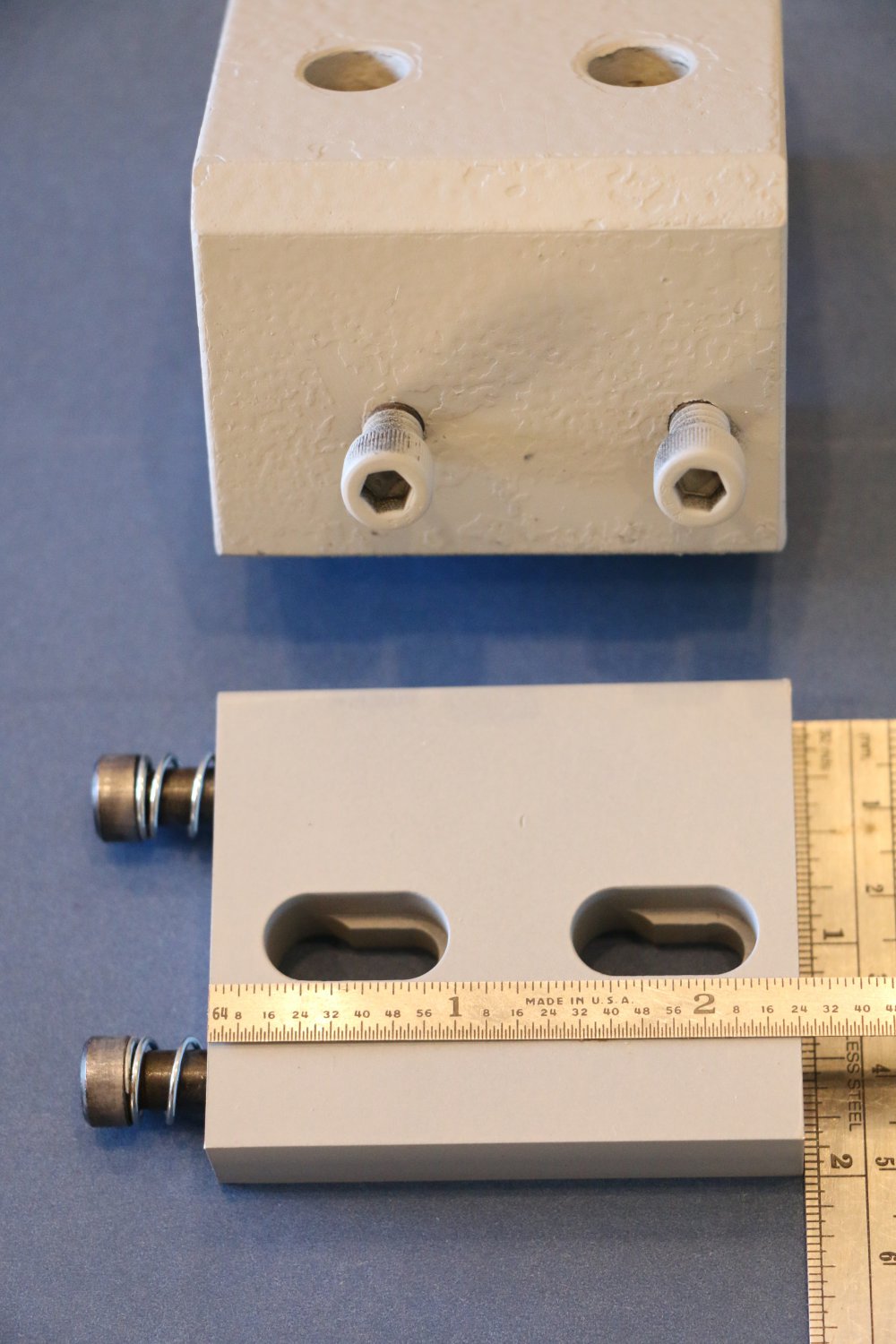

It is composed of two major components both made from 1/2" aluminum plate.

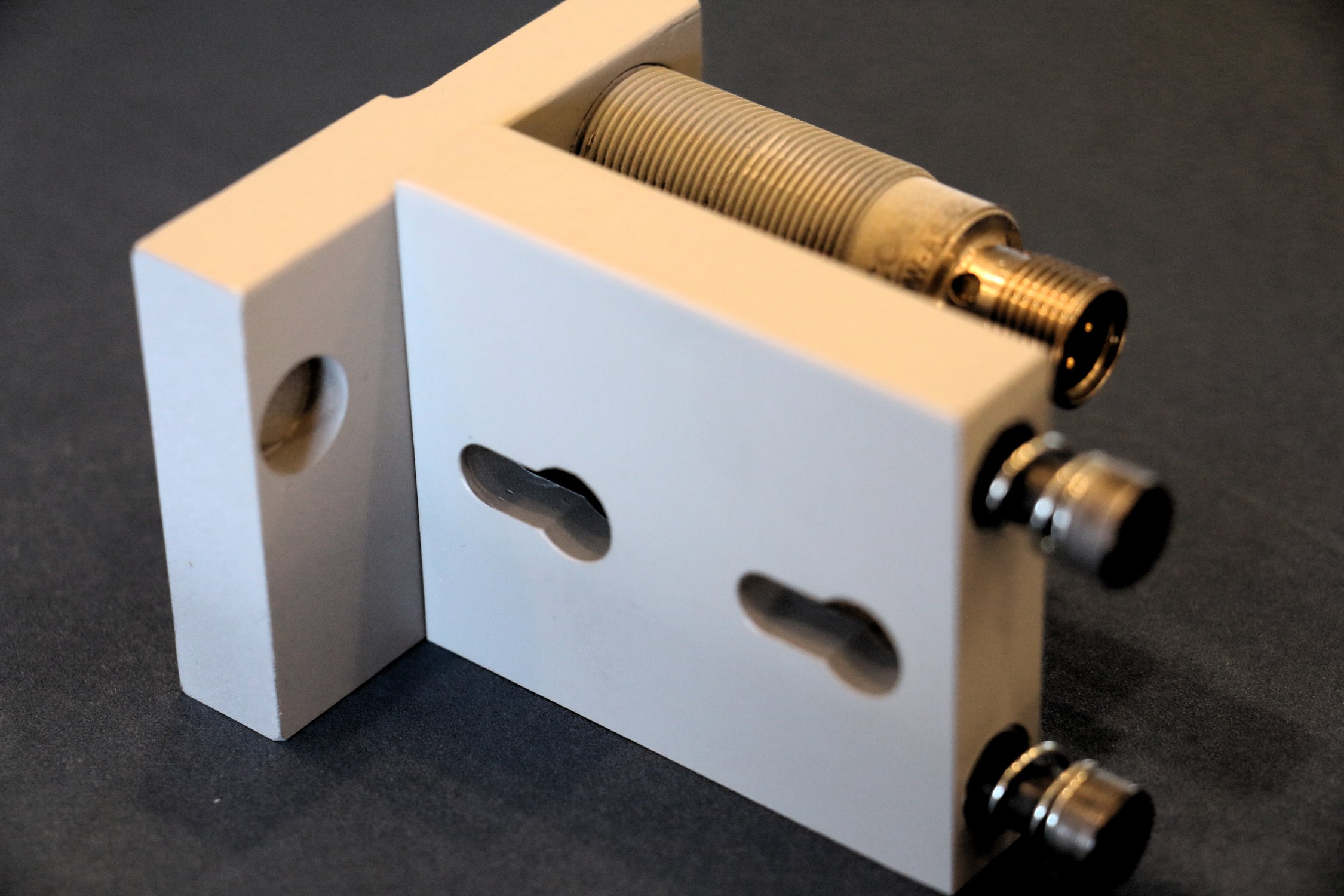

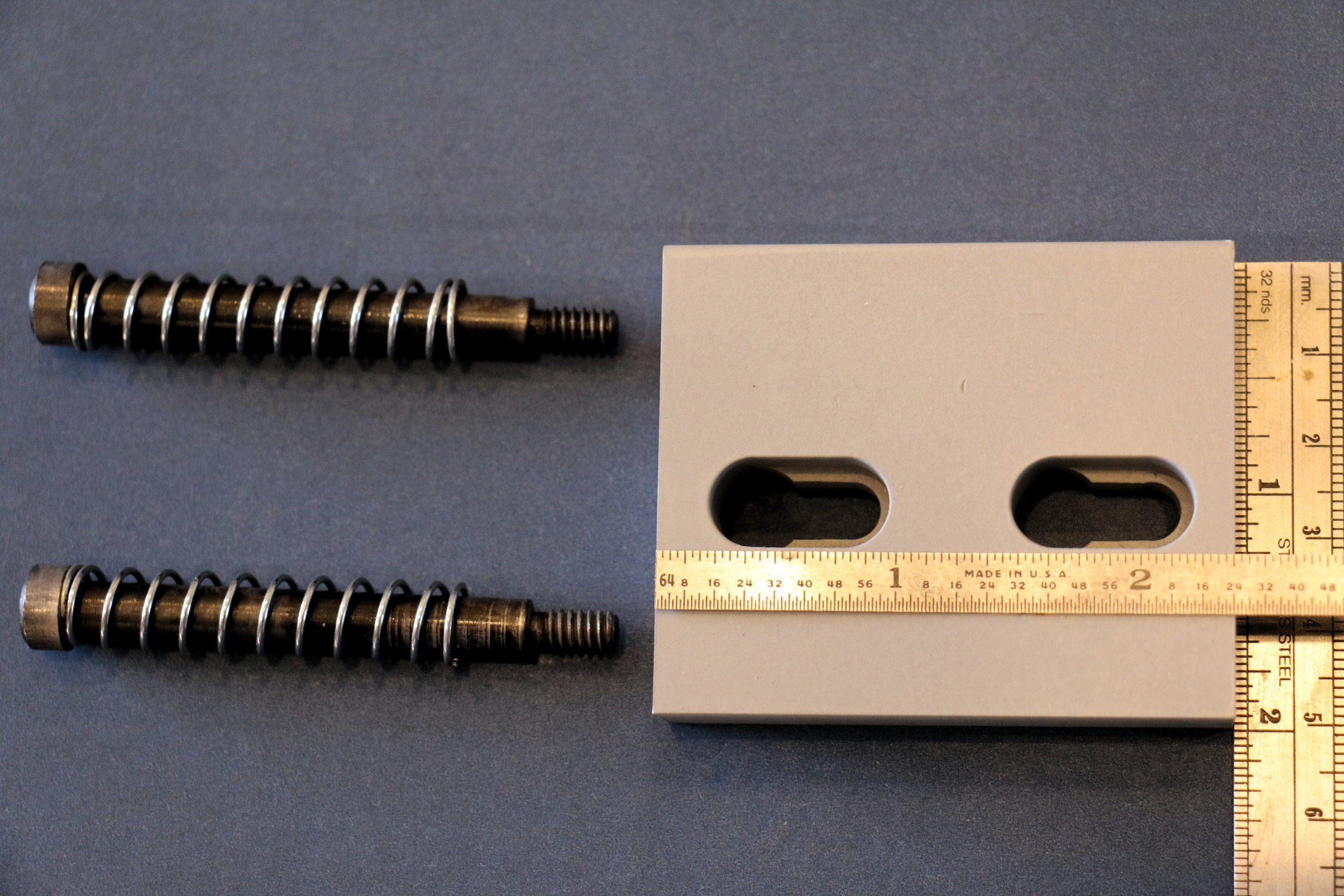

The mounting plate uses two 1/4 -20 socket screws to attach to the micrometer stop. Slots allow for slipping the plate over the socket heads then sliding to set proper location of the front plate.

The mounting plate has two holes drilled for shoulder screws and springs. These provide the force to return the front plate to the rear position.

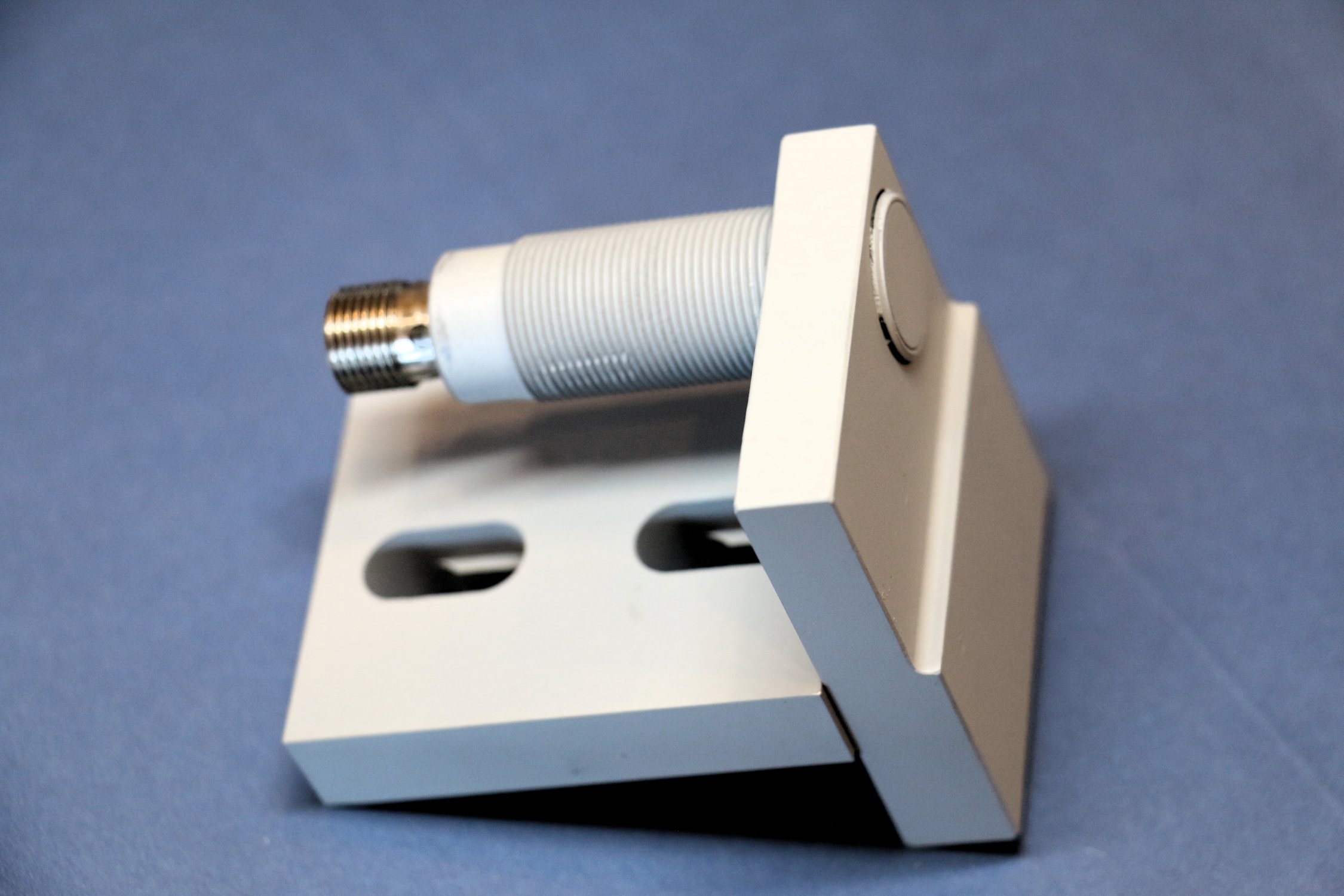

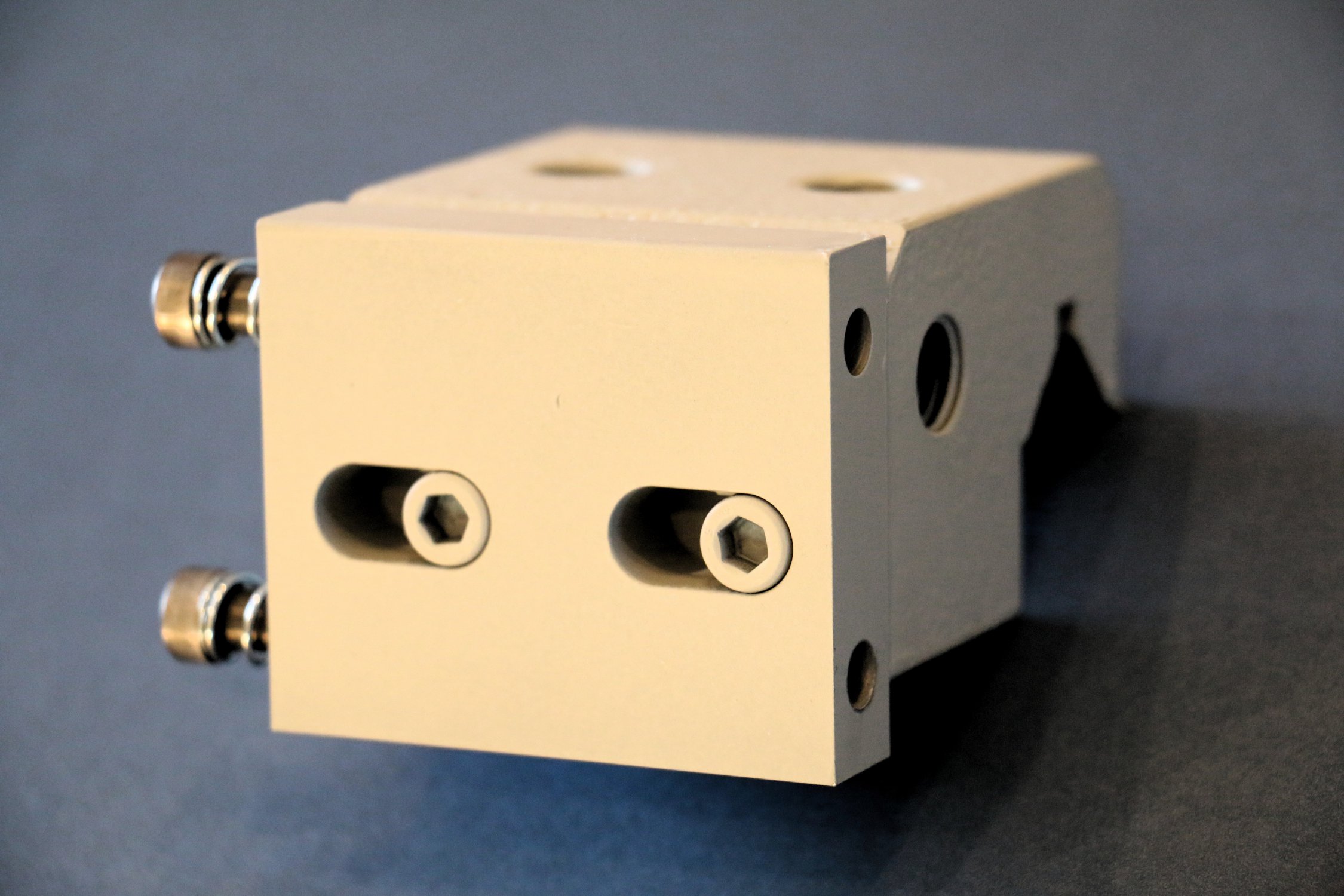

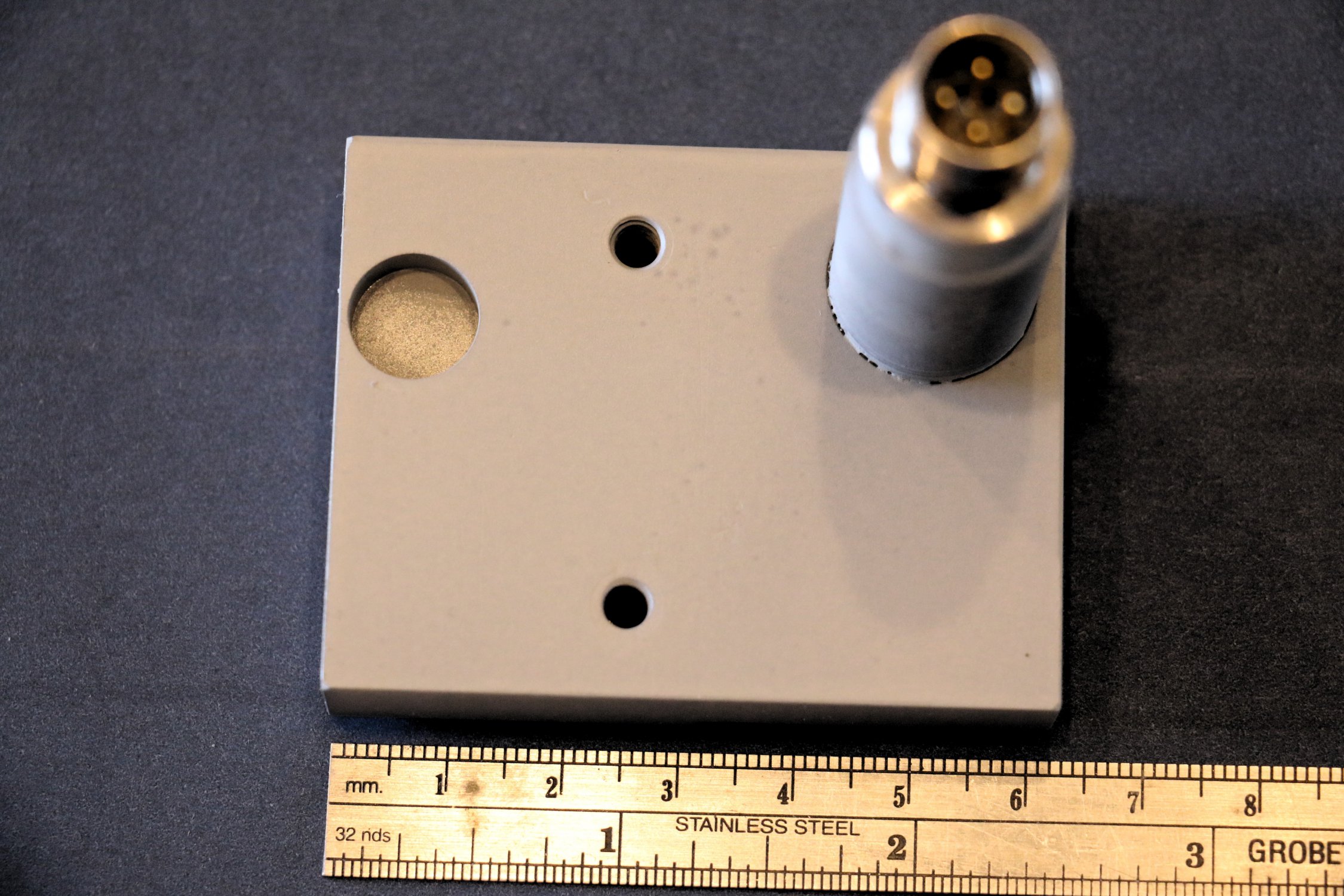

The front plate houses the prox sensor and attaches via the shoulder screws. It has a slot cut to allow the face of the sensor to be recessed preventing the sensor from contacting the carriage.

The rear has a cut out for the micrometer shaft. Since the shaft sits proud of the micrometer stop face the recess allows the front plate to sit flat against the micrometer stop.

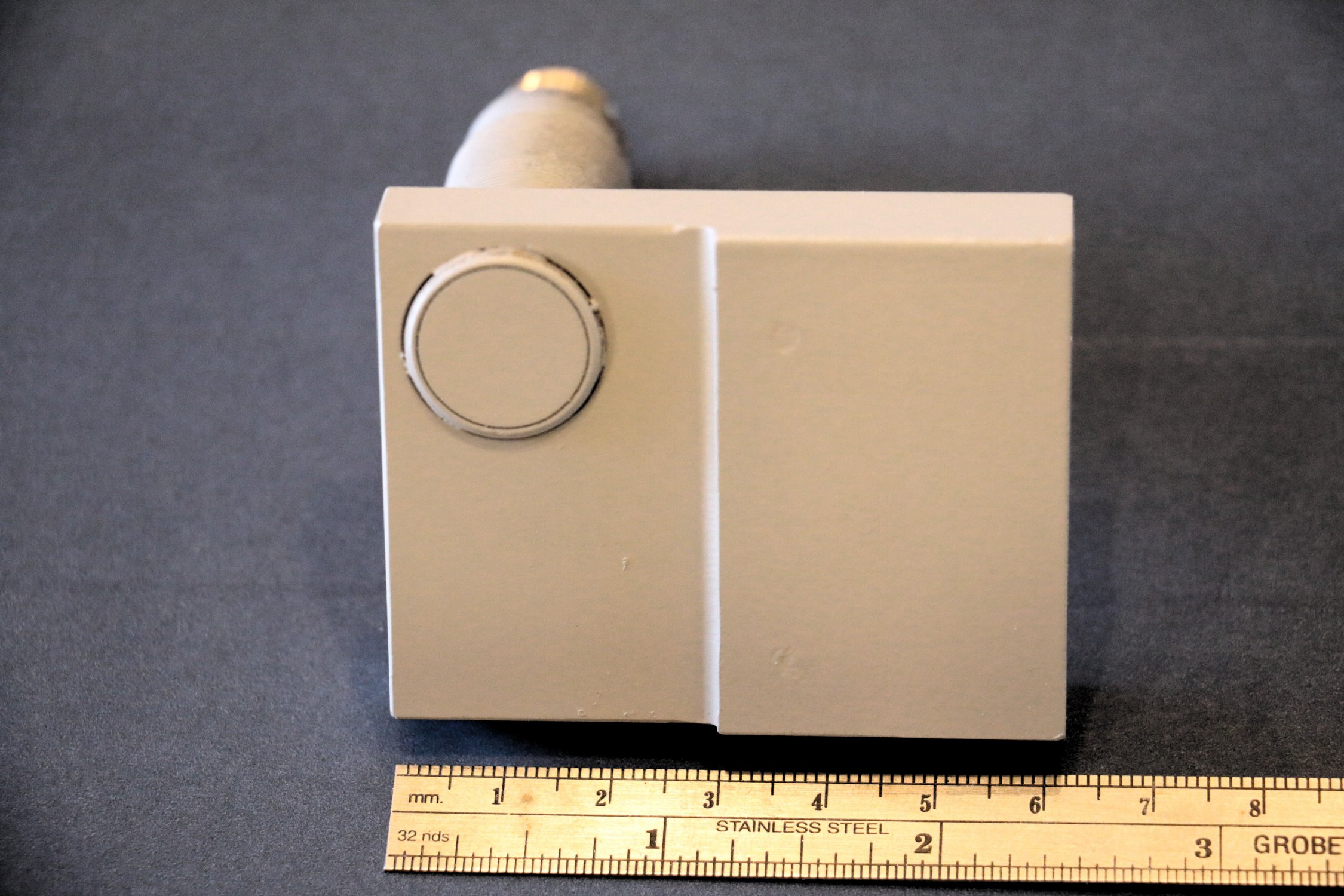

Mounted on the lathe. Note quick detach plug and panel mount attached to the head stock.

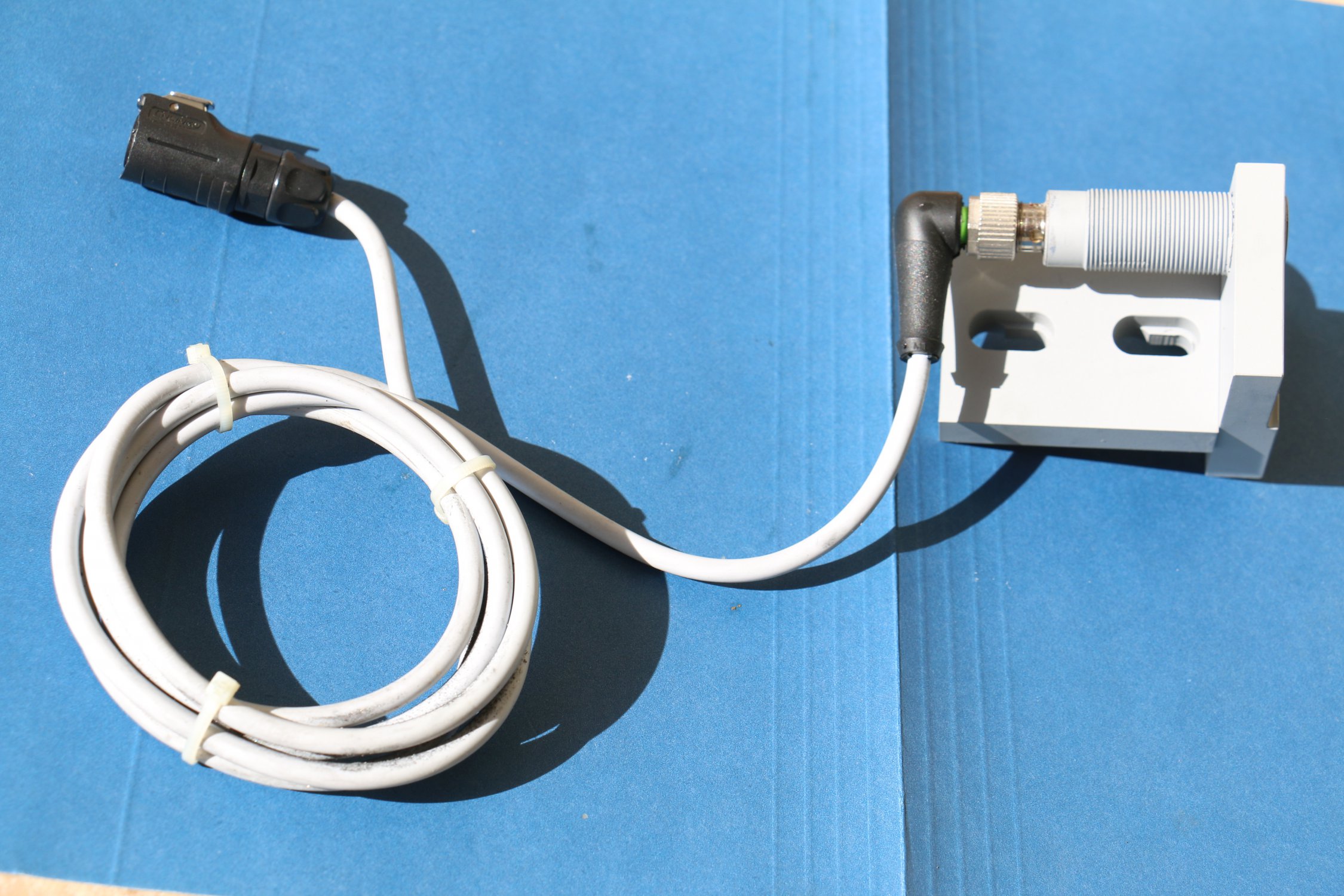

Complete unit. Removal/mounting via two socket screws and quick attach cable mount.

The way I Incorporated the sensor into the lathe control circuit was a version used by bench https://www.hobby-machinist.com/thr...-control-board-and-switches.49022/post-446310

Setup works great. Cut a 1-3/8 x 24 tpi thread in 17-4 SS @ 500 rpm to a close shoulder. Stopped +/- 0.002 on each pass.

Thanks Mark and "bench" for providing the background info to make this possible.

Second, since I have a VFD installed using the original lathe relays as outlined by Mark "mksj" I needed to find a way to integrate the sensor stop/start signal into the existing lathe setup.

First, the sensor micrometer stop design.

It is composed of two major components both made from 1/2" aluminum plate.

The mounting plate uses two 1/4 -20 socket screws to attach to the micrometer stop. Slots allow for slipping the plate over the socket heads then sliding to set proper location of the front plate.

The mounting plate has two holes drilled for shoulder screws and springs. These provide the force to return the front plate to the rear position.

The front plate houses the prox sensor and attaches via the shoulder screws. It has a slot cut to allow the face of the sensor to be recessed preventing the sensor from contacting the carriage.

The rear has a cut out for the micrometer shaft. Since the shaft sits proud of the micrometer stop face the recess allows the front plate to sit flat against the micrometer stop.

Mounted on the lathe. Note quick detach plug and panel mount attached to the head stock.

Complete unit. Removal/mounting via two socket screws and quick attach cable mount.

The way I Incorporated the sensor into the lathe control circuit was a version used by bench https://www.hobby-machinist.com/thr...-control-board-and-switches.49022/post-446310

Setup works great. Cut a 1-3/8 x 24 tpi thread in 17-4 SS @ 500 rpm to a close shoulder. Stopped +/- 0.002 on each pass.

Thanks Mark and "bench" for providing the background info to make this possible.

Last edited: