- Joined

- Aug 19, 2014

- Messages

- 225

I blame this loss of savings mostly on Enco. Two 30% off offers in a row is just more than a guy can handle when he's pining for some new tool. So a new Enco 12 x 36 Model 411-0105 bench lathe is my big investment for the year. Looked and looked at used and others. Oil boom has sucked up most decent machines and what does show up is somewhat over priced or just ratted out. Not a lot of manufacturing/job shop stuff in west Texas anyway. Helping to push me into it was a discussion over on the 12x36 Yahoo group. There is a post from someone that just bought this same machine in July. He said it came equipped much like the Griz 4003 including a piston type tool post. Didn't match the catalog, looked better out of the box so to speak. And it turned out to be just so, so far.

I'll try to blog/detail my experience with this thing and maybe that will help someone down the road with a purchase.

------

The trucking company kinda forgot to call, so when I called Enco to get a delivery update it turned out it was sitting on the doc at the local Southeastern Freight terminal. I took a long lunch from work to run home and get the truck and flat bed trailer, then go pick it up.

The end by the lift is for sure the heavy end. Gross weight per box is 530 kg/1166 lbs.

Secured for the trip to the shop.

- - - Updated - - -

Copy of the Enco catalog page at time of purchase. Their site is really weird. A search on "lathe" or clicking through to the Machinery, Lathes, Lathes-Bench, Brand Enco does not show the purchased part number. It's in the catalog and can be located on a different web page with google - http://www.use-enco.com/1/1/96912-bench ... -0105.html As you'll see below, the real deal differes from the picture a bit.

- - - Updated - - -

Snatching it off the trailer was a bit of a trick. It took a couple of tries to find a decent balance point.

With the wife's guiding hand, it rests on the hoist.

- - - Updated - - -

After a bit of finagling, I got it off the hoist on to the floor. Nothing like the picture, is it? It does match the description posted on the Yahoo 12x36 group by a recent purchaser. The splash guard is behind the machine and the chip pan is propped on the mower. The QCTP is a Series 200 and it came with a -201 and -202 tool holder. Tool box, cool red oil can, big 4 jaw chuck and the usual misc. The work light has what looks like a regular bulb in it, so I may hack that to LED. Nice to have for any reason. Not sure what I was expecting, but having spent years with a 9x20 this thing is HUGE. The overall condition of the machine is good and a bit greasy/dirty. Going to use a lot of WD-40 cleaning on this guy.

It'll be a little while before it's running. I'll start on the stand now that I have the chip pan to use for a pattern. I plan to run 12-3 to the machine for both 240 and 120 service on the stand. I sourced some Cooper Wiring twist lock 20 amp plugs from Amazon, way cheaper than HD or Lowes. 50' of 12-3 is around $60.

Gearbox Face plate. End cover on the left is cast fiberglass.

Aerial view

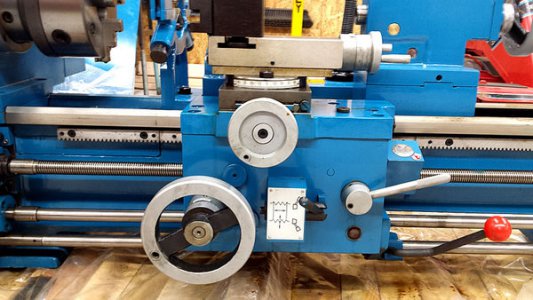

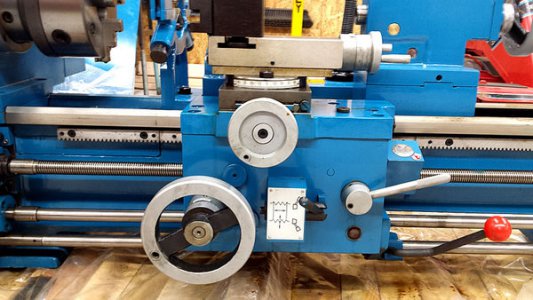

Carriage

- - - Updated - - -

Finally got the thing off the skid and on wheels. That's not a balance point, but it was enough to let me lift the tail end and slide the skid out from under. The lathe is now parked off to the side - I still have to get a sick race car in here this weekend for some tuning so I'm trying to clear a space. The home made roller under the headstock uses some casters that I got off a scrapped IT server bench rated at around 1000 lbs. I usually have a transmission or engine block on it.

Sizing up the eventual parking space.

The tool box contained with this cool bright red oil can. I took a picture and showed it to a lady I work with that is from Malaysia. She read the company name and said "Those are the same people that sell rice wine." Diversified economy, indeed.

Stand build is next, will be on that in a few days. Depends on time available for shop work.

I'll try to blog/detail my experience with this thing and maybe that will help someone down the road with a purchase.

------

The trucking company kinda forgot to call, so when I called Enco to get a delivery update it turned out it was sitting on the doc at the local Southeastern Freight terminal. I took a long lunch from work to run home and get the truck and flat bed trailer, then go pick it up.

The end by the lift is for sure the heavy end. Gross weight per box is 530 kg/1166 lbs.

Secured for the trip to the shop.

- - - Updated - - -

Copy of the Enco catalog page at time of purchase. Their site is really weird. A search on "lathe" or clicking through to the Machinery, Lathes, Lathes-Bench, Brand Enco does not show the purchased part number. It's in the catalog and can be located on a different web page with google - http://www.use-enco.com/1/1/96912-bench ... -0105.html As you'll see below, the real deal differes from the picture a bit.

- - - Updated - - -

Snatching it off the trailer was a bit of a trick. It took a couple of tries to find a decent balance point.

With the wife's guiding hand, it rests on the hoist.

- - - Updated - - -

After a bit of finagling, I got it off the hoist on to the floor. Nothing like the picture, is it? It does match the description posted on the Yahoo 12x36 group by a recent purchaser. The splash guard is behind the machine and the chip pan is propped on the mower. The QCTP is a Series 200 and it came with a -201 and -202 tool holder. Tool box, cool red oil can, big 4 jaw chuck and the usual misc. The work light has what looks like a regular bulb in it, so I may hack that to LED. Nice to have for any reason. Not sure what I was expecting, but having spent years with a 9x20 this thing is HUGE. The overall condition of the machine is good and a bit greasy/dirty. Going to use a lot of WD-40 cleaning on this guy.

It'll be a little while before it's running. I'll start on the stand now that I have the chip pan to use for a pattern. I plan to run 12-3 to the machine for both 240 and 120 service on the stand. I sourced some Cooper Wiring twist lock 20 amp plugs from Amazon, way cheaper than HD or Lowes. 50' of 12-3 is around $60.

Gearbox Face plate. End cover on the left is cast fiberglass.

Aerial view

Carriage

- - - Updated - - -

Finally got the thing off the skid and on wheels. That's not a balance point, but it was enough to let me lift the tail end and slide the skid out from under. The lathe is now parked off to the side - I still have to get a sick race car in here this weekend for some tuning so I'm trying to clear a space. The home made roller under the headstock uses some casters that I got off a scrapped IT server bench rated at around 1000 lbs. I usually have a transmission or engine block on it.

Sizing up the eventual parking space.

The tool box contained with this cool bright red oil can. I took a picture and showed it to a lady I work with that is from Malaysia. She read the company name and said "Those are the same people that sell rice wine." Diversified economy, indeed.

Stand build is next, will be on that in a few days. Depends on time available for shop work.

Last edited by a moderator: