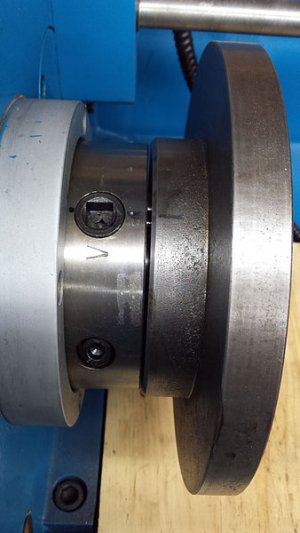

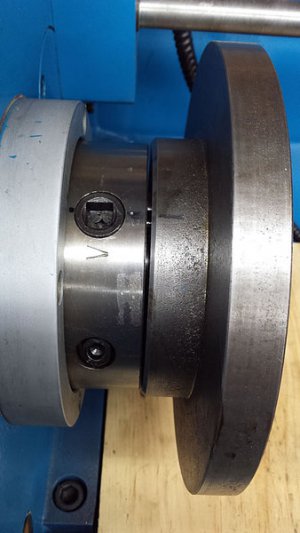

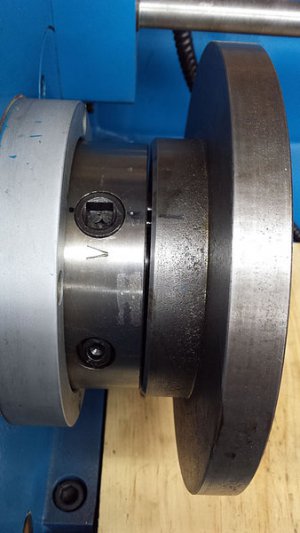

I finally got the three jaw to talk right, after a bit of work. I mounted the chuck, then tweaked it a bit using an indicator on the OD. When I got that close, I put the test bar in the jaws. I had to run the jaws around again to find the best TIR. Once I got that, I tweaked the chuck on the plate using the indicator on the test bar and the tip up next to the jaws. Best I could get was .002 TIR at the jaws, .0035 4" out. At that point I center punched dots on the jaws and chuck in the channels. I went around the chuck and used each scroll screw until I found the one that repeated the TIR. Gave that one a punch mark. Calling it "good 'nuff".

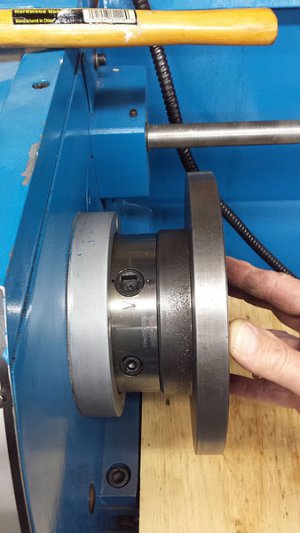

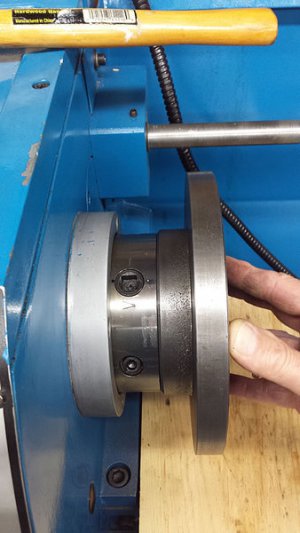

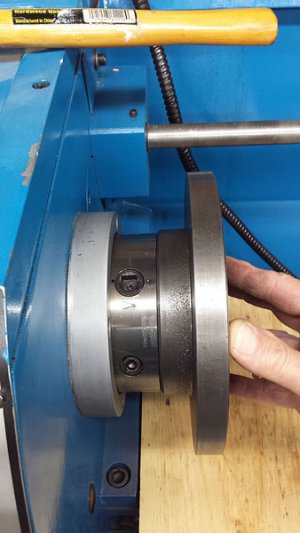

Now for the 4 jaw. The plate doesn't want to pull up to the spindle face evenly in any position, so I'm using a marker to find any tight spots on the taper and massaging the taper slowly with 320 grit/WD-40. I got it to go .003 once, but could not get the cams to repeat at any torque. It looks like a swash plate in all three positions using a breaker bar on the cams. I'll either sneak up on it or have to get another plate. It stands about .003~.004 proud before pull it in with the cams. No matter how may time I go around, there is a spot that won't pull up tight. Ran out of time to mess with it, so more on that later.