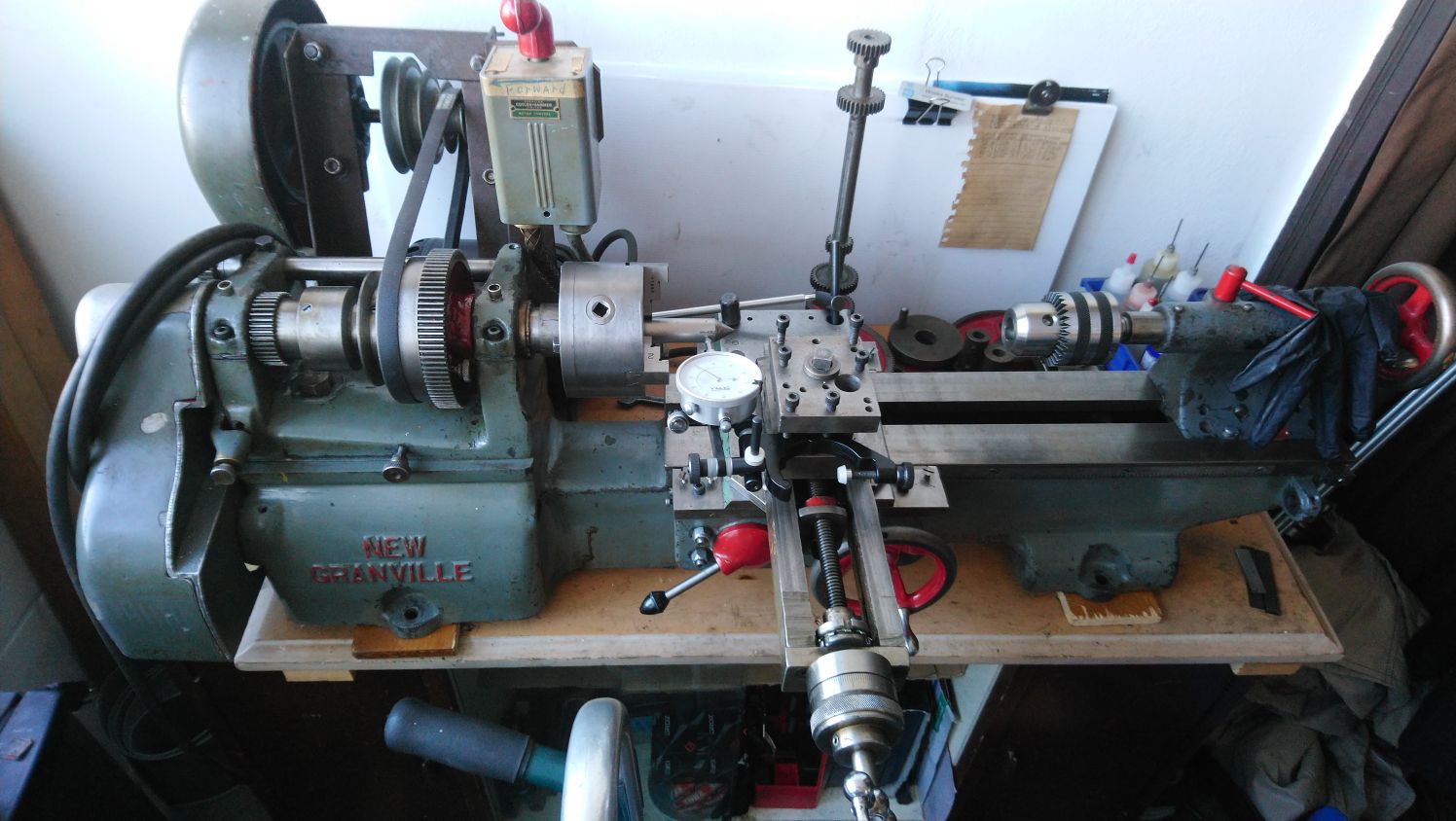

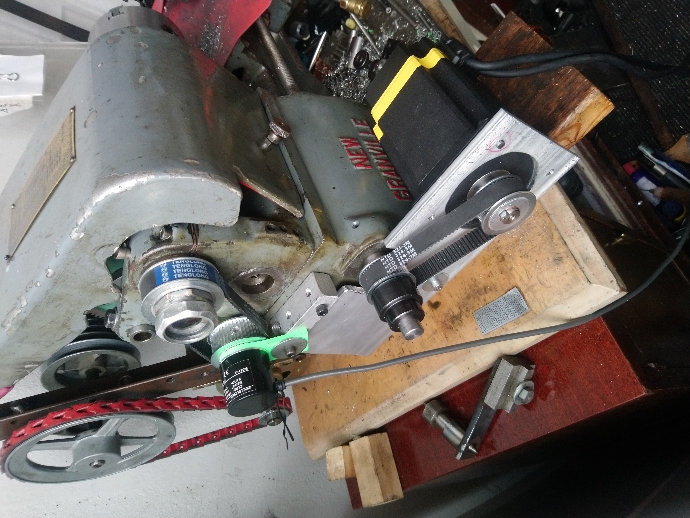

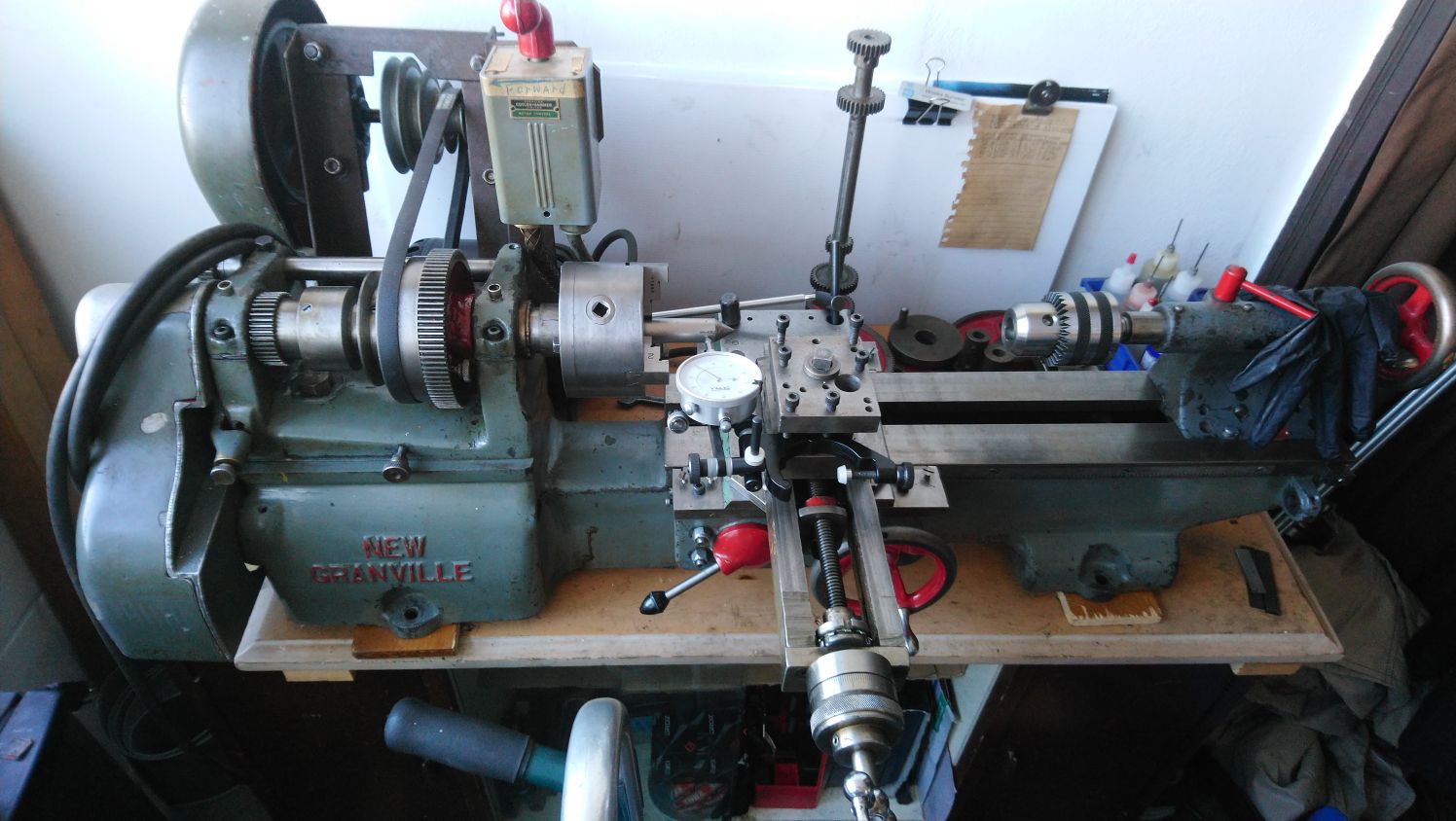

A while back I got a New Granville 7x18 gap bed lathe covered in oil/ dirt/ sawdust and in a sad state. Backgear shaft and backgears, cross slide and topslide, leadscrew and bushings, threading dial, and preload adjuster nut were all missing. It came with a saddle made from steel plate (hack job) with the original apron attached and an unusually large (I'm being conservative in that description) home made angle adjustable cross slide bolted on top. The tailstock was cut down from a much larger machine, height was perfect but alignment was terrible. Countershaft assembly was a home job, skew and out of alignment, and motor was caked with sawdust inside and out but it ran well? I think this had been modified to use as a wood lathe but there were plenty of metal chips in all the crevices too.

The lathe is similar to a Myford ML7 but with much thicker heavier castings and seems far more rigid. Had to take it there and then so it went on the back seat on a tarp and a board. Nearly burst a kidney unloading the thing (had help loading it), it weighs more than I do.

A few Myford parts do fit this machine (none I needed), but those parts are not readily available. I have seen plenty of change gears around though, but don't need any of those either. I've seen plenty of rescues on the forums, but not many this adventurous. However, when I saw it I figured it was a chance at a truly rigid mini lathe, which is all I have space for in my micro shop.

After stripping and cleaning the machine, the first project was the spindle preload adjustment nut(s). 1⅛"-24? very fine thread. Found 2 nuts in the odds bin at the local bicycle shop, some vintage bikes had a header nut in 1⅛" thread. Both fit perfectly.

Made a leadscrew, ⅝-8 LH acme. Half nuts don't look used at all but not happy with the slight slop when closed, will do for now. I'll make a whole new mechanism soon as I don't like the design they used originally.

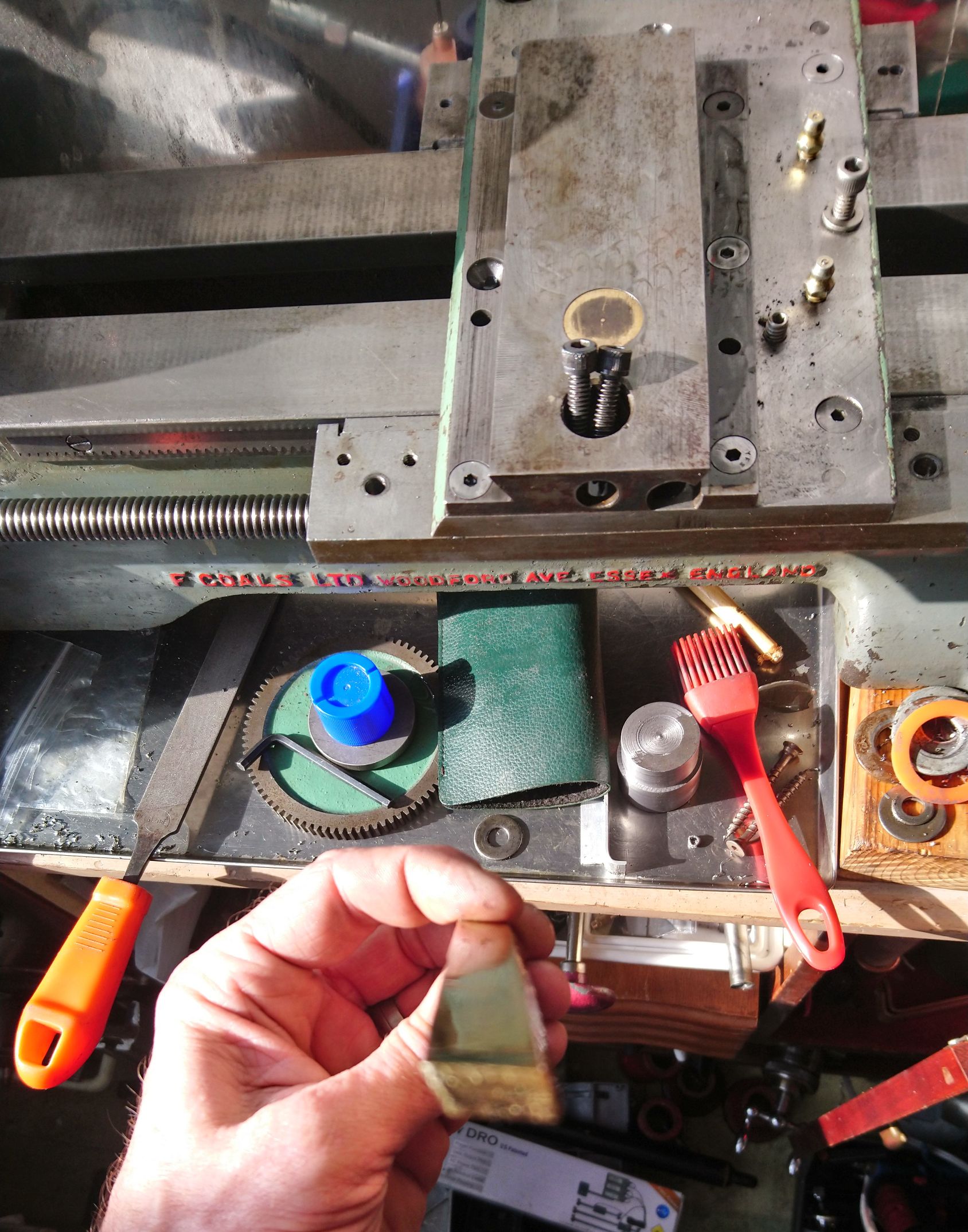

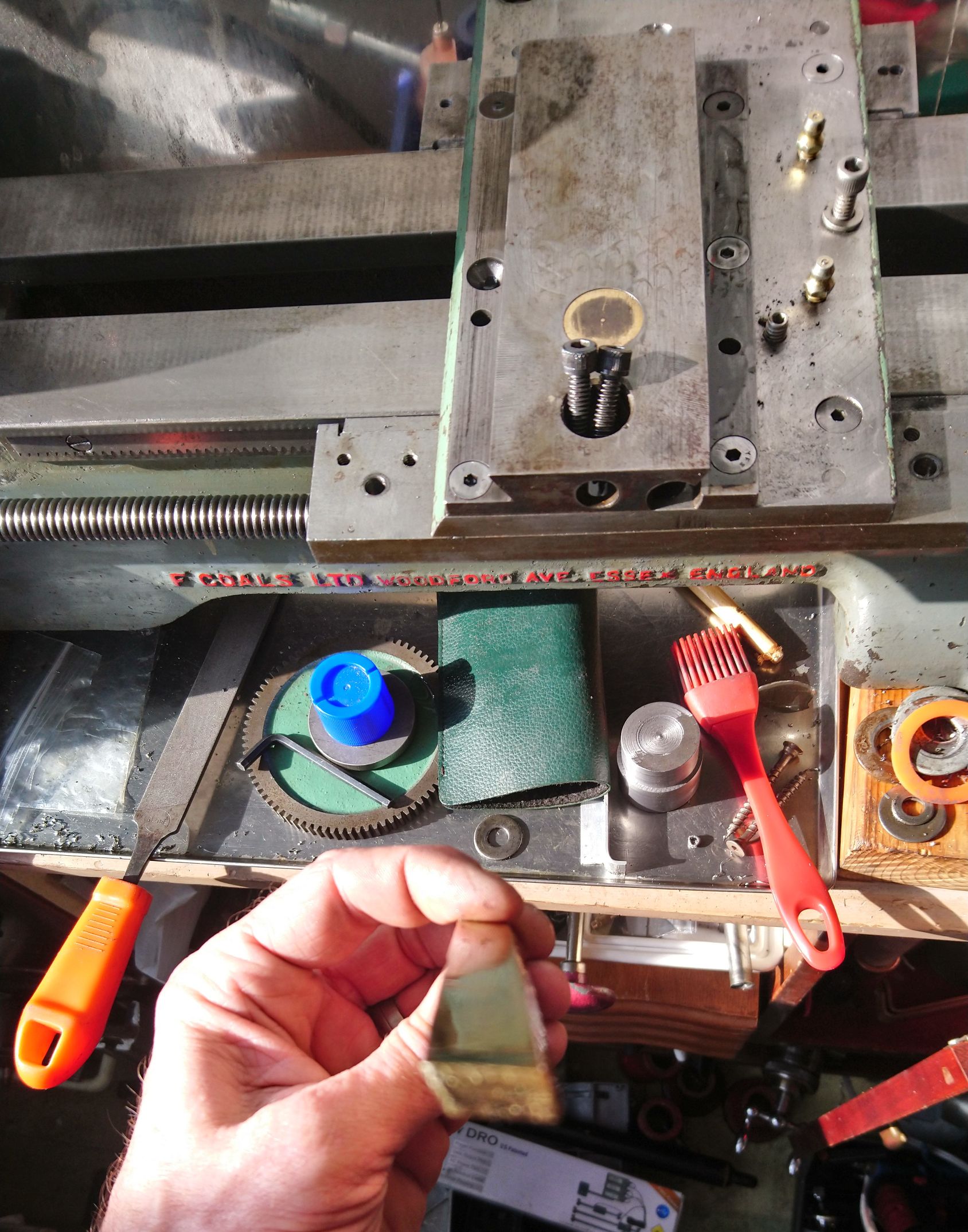

Next project was to make a tapered gib for the hardinge 9D cross slide. Didn't have my mill yet so I rough cut the brass gib with a hacksaw and sanded it by hand on the surface plate. Maybe dumb luck, but the gib fits and works perfectly.

Polished the parts of the carriage plate that contacts the ways and cut grooves to hold and distribute lube, trimmed it to fit the lathe better. Bolted the now operational 9D cross slide to the carriage. Fit isn't bad for the machine overall.

Got my hands on a new myford ml7 threading dial gear on flea Bay and made a threading dial.

First job for my new mill, which came in usable condition, almost. Recut lathe tailstock to align perfectly. Epoxied thin brass strips on the tailstock to slide on the inside of the ways.

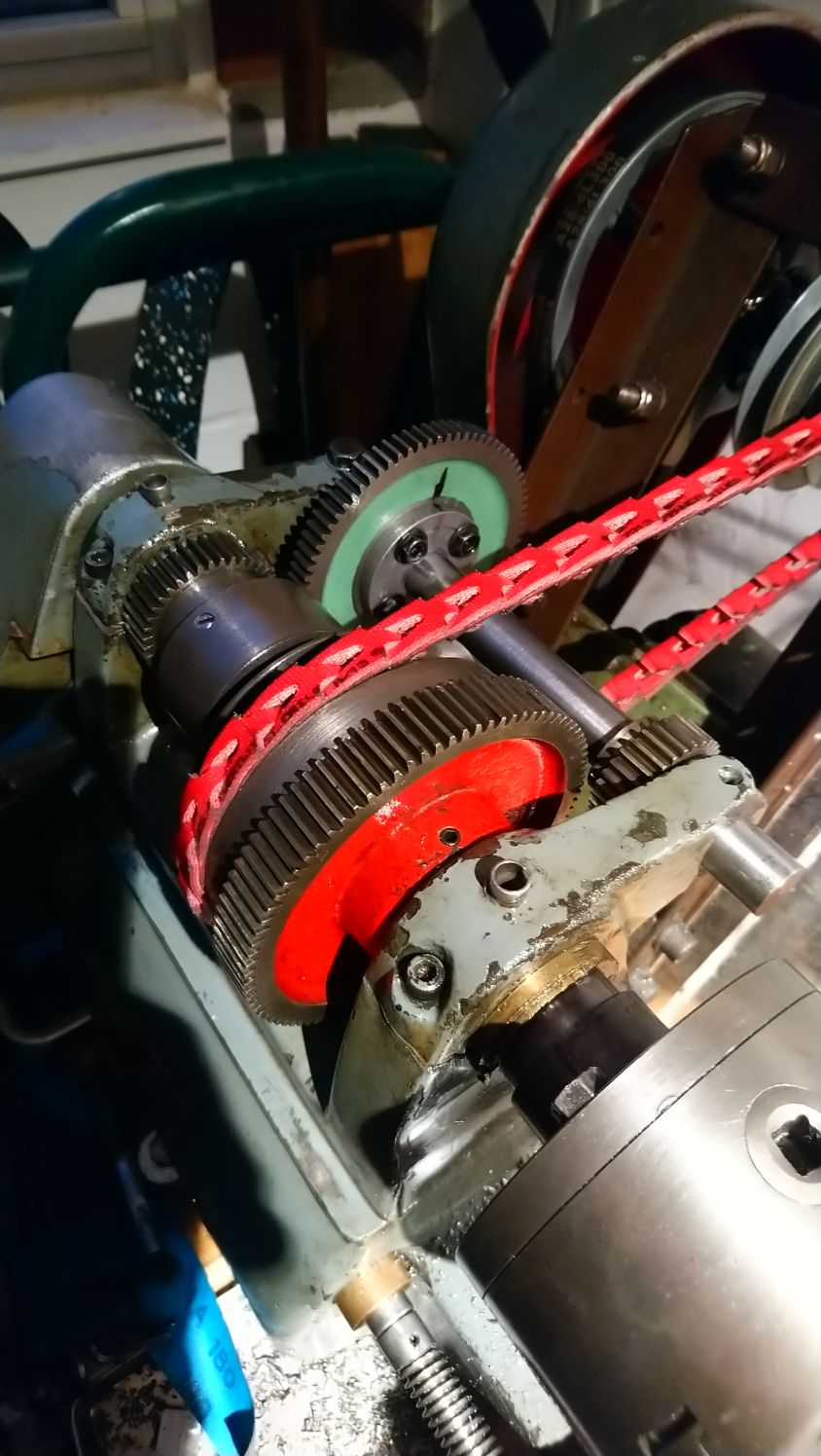

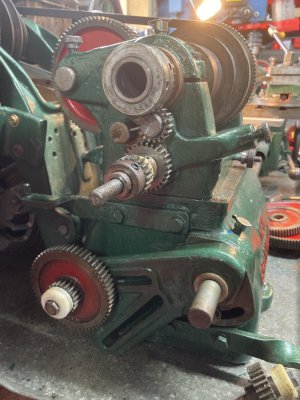

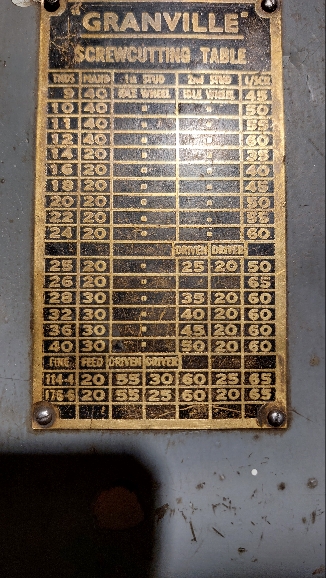

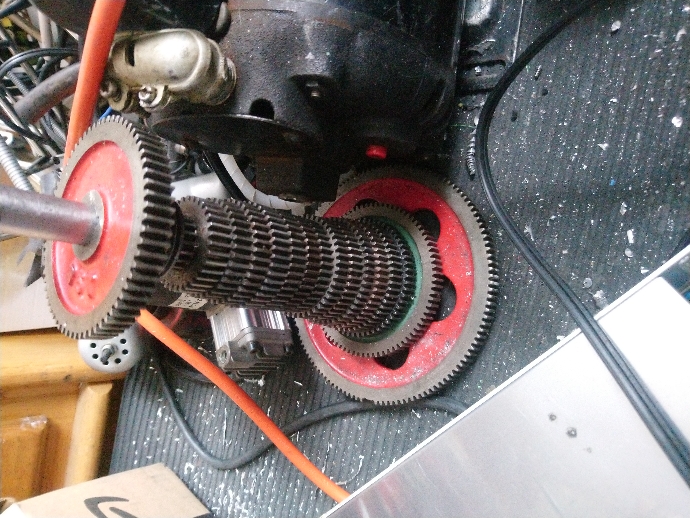

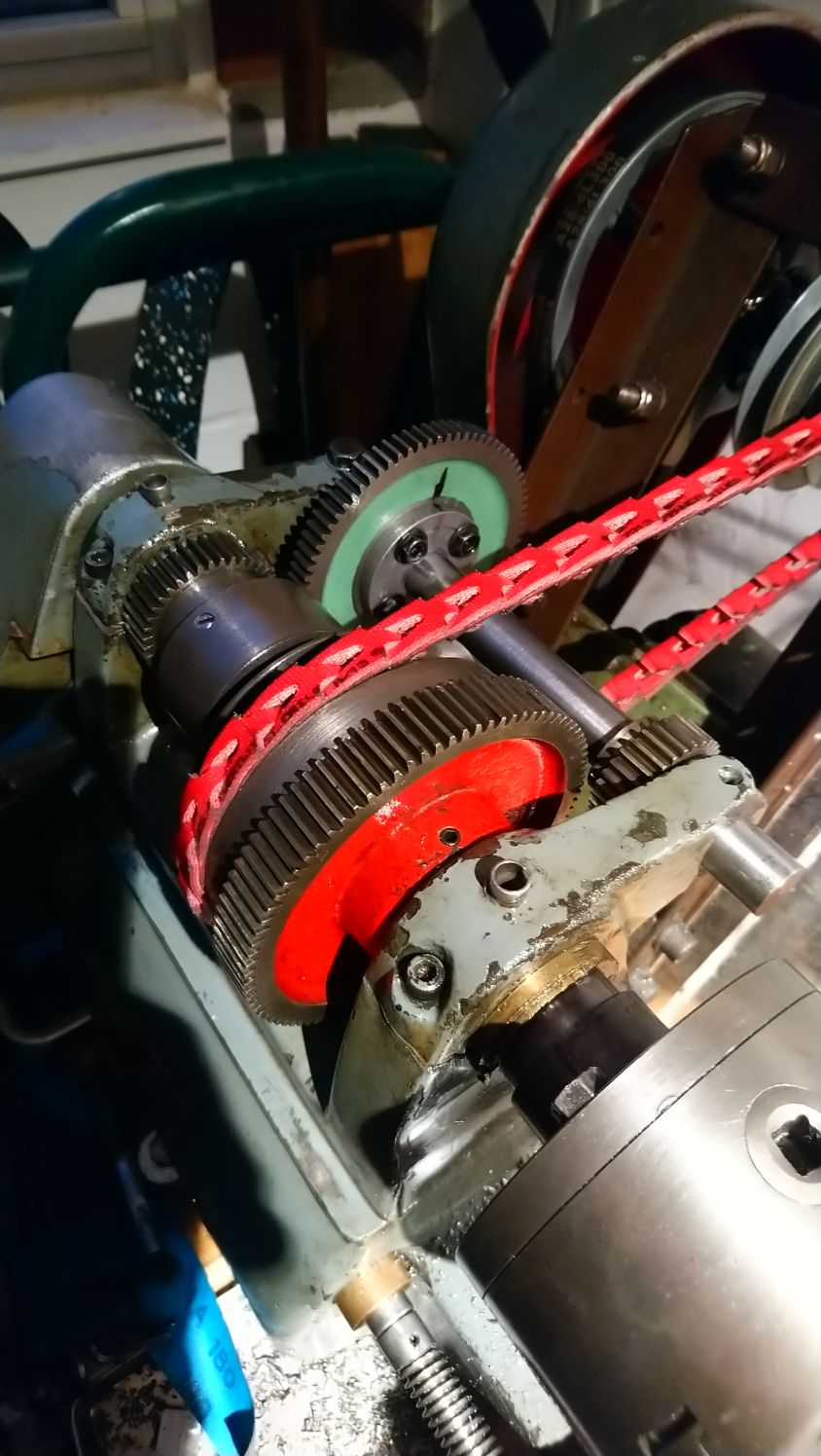

Made a shaft for the backgear and figured out what size gears I needed. All gears on the machine are 20DP. Found a nice 40 tooth gear that fit one end, modified an 80 tooth 20DP change-gear by adding a hub to either side and bolting it all together with four ¼" bolts, bored gear to fit shaft and assembled everything. Backgear runs with no extra noise which was a pleasant surprise.

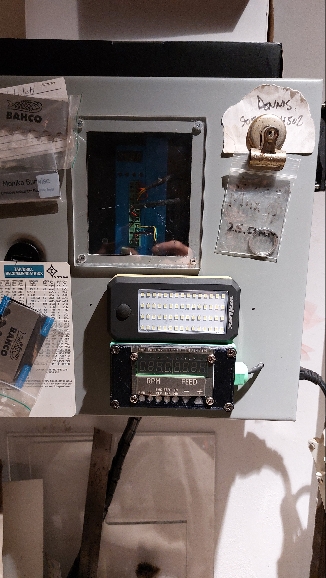

Very happy with my progress so far. Everything that was broken or missing is now fixed or replaced. Lathe is 100% functional. I don't plan to do anything to it cosmetically yet. Too busy enjoying it. Bit of an upgrade from my Craftsman Dunlap 6x18. It's a bastard machine with non-matching parts scavenged from other machines, but as luck would have it those parts are all more rigid and heavy duty than the originals. Ended up with a workhorse with 1 hp and cuts whatever I put in it with ease. Doesn't look too bad with all the original contrast colored (bright red) hand wheels, levers and knobs either.

The lathe is similar to a Myford ML7 but with much thicker heavier castings and seems far more rigid. Had to take it there and then so it went on the back seat on a tarp and a board. Nearly burst a kidney unloading the thing (had help loading it), it weighs more than I do.

A few Myford parts do fit this machine (none I needed), but those parts are not readily available. I have seen plenty of change gears around though, but don't need any of those either. I've seen plenty of rescues on the forums, but not many this adventurous. However, when I saw it I figured it was a chance at a truly rigid mini lathe, which is all I have space for in my micro shop.

After stripping and cleaning the machine, the first project was the spindle preload adjustment nut(s). 1⅛"-24? very fine thread. Found 2 nuts in the odds bin at the local bicycle shop, some vintage bikes had a header nut in 1⅛" thread. Both fit perfectly.

Made a leadscrew, ⅝-8 LH acme. Half nuts don't look used at all but not happy with the slight slop when closed, will do for now. I'll make a whole new mechanism soon as I don't like the design they used originally.

Next project was to make a tapered gib for the hardinge 9D cross slide. Didn't have my mill yet so I rough cut the brass gib with a hacksaw and sanded it by hand on the surface plate. Maybe dumb luck, but the gib fits and works perfectly.

Polished the parts of the carriage plate that contacts the ways and cut grooves to hold and distribute lube, trimmed it to fit the lathe better. Bolted the now operational 9D cross slide to the carriage. Fit isn't bad for the machine overall.

Got my hands on a new myford ml7 threading dial gear on flea Bay and made a threading dial.

First job for my new mill, which came in usable condition, almost. Recut lathe tailstock to align perfectly. Epoxied thin brass strips on the tailstock to slide on the inside of the ways.

Made a shaft for the backgear and figured out what size gears I needed. All gears on the machine are 20DP. Found a nice 40 tooth gear that fit one end, modified an 80 tooth 20DP change-gear by adding a hub to either side and bolting it all together with four ¼" bolts, bored gear to fit shaft and assembled everything. Backgear runs with no extra noise which was a pleasant surprise.

Very happy with my progress so far. Everything that was broken or missing is now fixed or replaced. Lathe is 100% functional. I don't plan to do anything to it cosmetically yet. Too busy enjoying it. Bit of an upgrade from my Craftsman Dunlap 6x18. It's a bastard machine with non-matching parts scavenged from other machines, but as luck would have it those parts are all more rigid and heavy duty than the originals. Ended up with a workhorse with 1 hp and cuts whatever I put in it with ease. Doesn't look too bad with all the original contrast colored (bright red) hand wheels, levers and knobs either.