- Joined

- May 20, 2014

- Messages

- 191

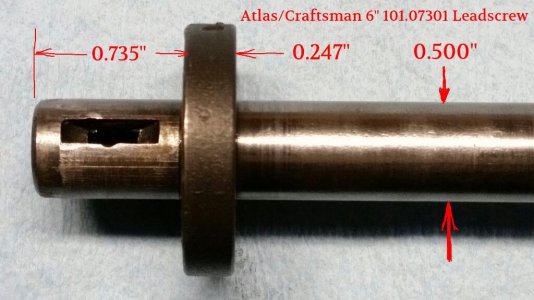

I've been meaning to replace the 65 year old leadscrew on my Atlas/Craftsman 6x18 101.07301 6" lathe for over 25 years.

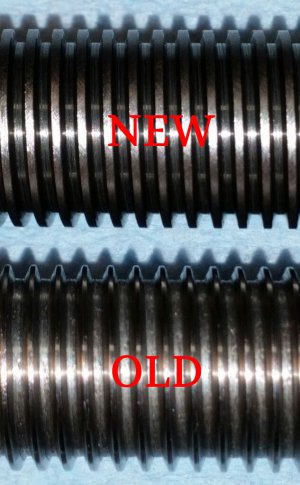

The Acme threads look like V-threads in the middle of the screw.

I had investigated 3 options:

1- Cut/machine/join a piece of precision Acme threaded rod to the original.

-- Couldn't find precision 1/2" - 16 TPI Acme rod, without expensive special order.

2- Acquire an eBay item.

-- After looking at various eBay $25-$100 offerings, I just knew there would be wear and other secret problems.

3- Buy a new one from Clausing or Sears.

-- Sears wanted $180, Clausing $148

The new LeadScrew from Clausing arrived in 3 days in a stout cardboard tube.

It had been pickled and wrapped very thoroughly.:ups:

The original part number, L9-35, has been superceded by part number 3950-16, which includes the fitted thrust collar.

The parts support representative at Clausing said they had been out-of-stock, and have replenished the supply from a new run in September 2014.

Clausing Service Center

2019 North Pitcher St.

Kalamazoo, Michigan 49007-1822

(800) 323-0972

The Acme threads look like V-threads in the middle of the screw.

I had investigated 3 options:

1- Cut/machine/join a piece of precision Acme threaded rod to the original.

-- Couldn't find precision 1/2" - 16 TPI Acme rod, without expensive special order.

2- Acquire an eBay item.

-- After looking at various eBay $25-$100 offerings, I just knew there would be wear and other secret problems.

3- Buy a new one from Clausing or Sears.

-- Sears wanted $180, Clausing $148

The new LeadScrew from Clausing arrived in 3 days in a stout cardboard tube.

It had been pickled and wrapped very thoroughly.:ups:

The original part number, L9-35, has been superceded by part number 3950-16, which includes the fitted thrust collar.

The parts support representative at Clausing said they had been out-of-stock, and have replenished the supply from a new run in September 2014.

Clausing Service Center

2019 North Pitcher St.

Kalamazoo, Michigan 49007-1822

(800) 323-0972

Last edited by a moderator: