- Joined

- Oct 27, 2016

- Messages

- 286

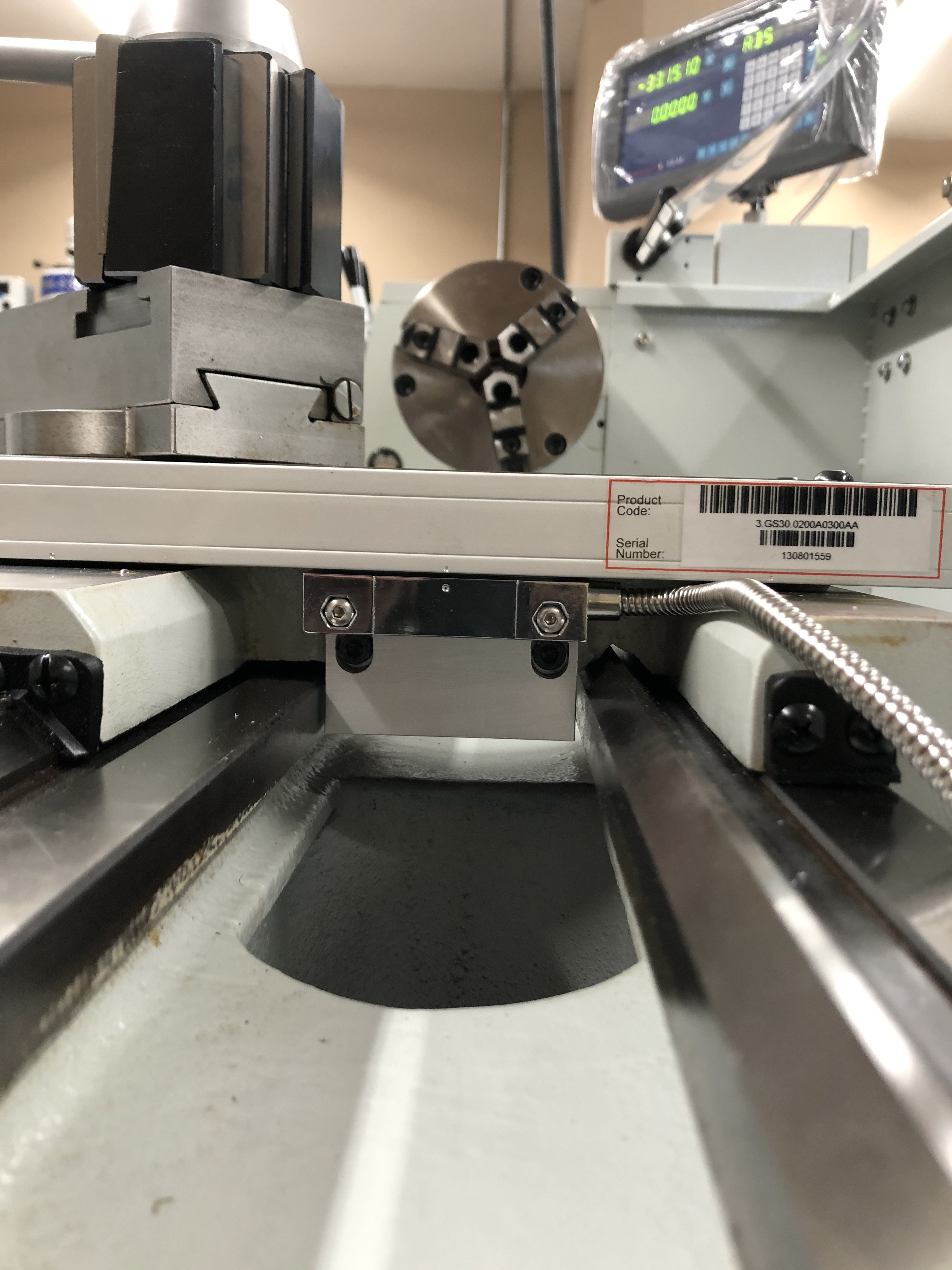

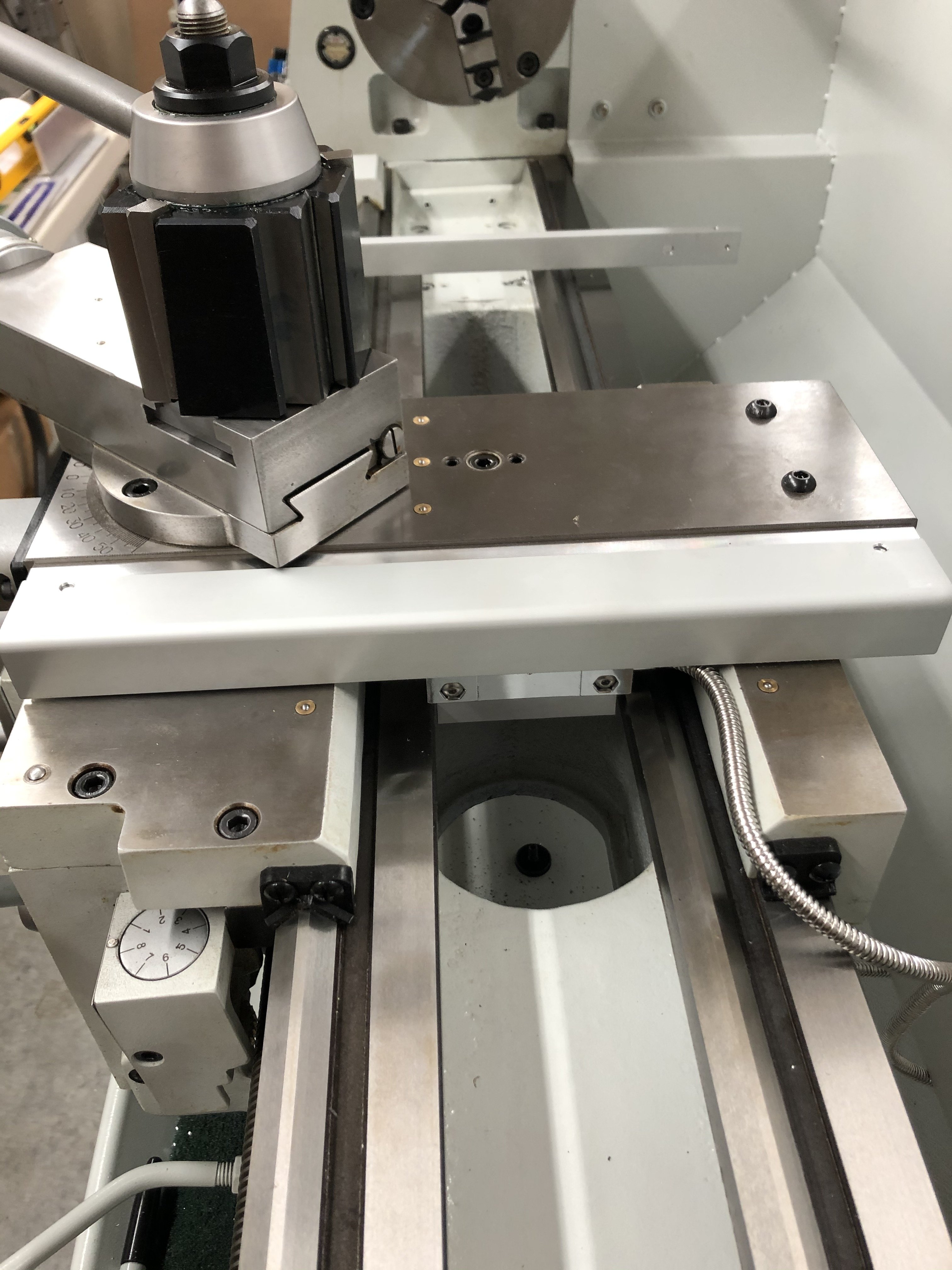

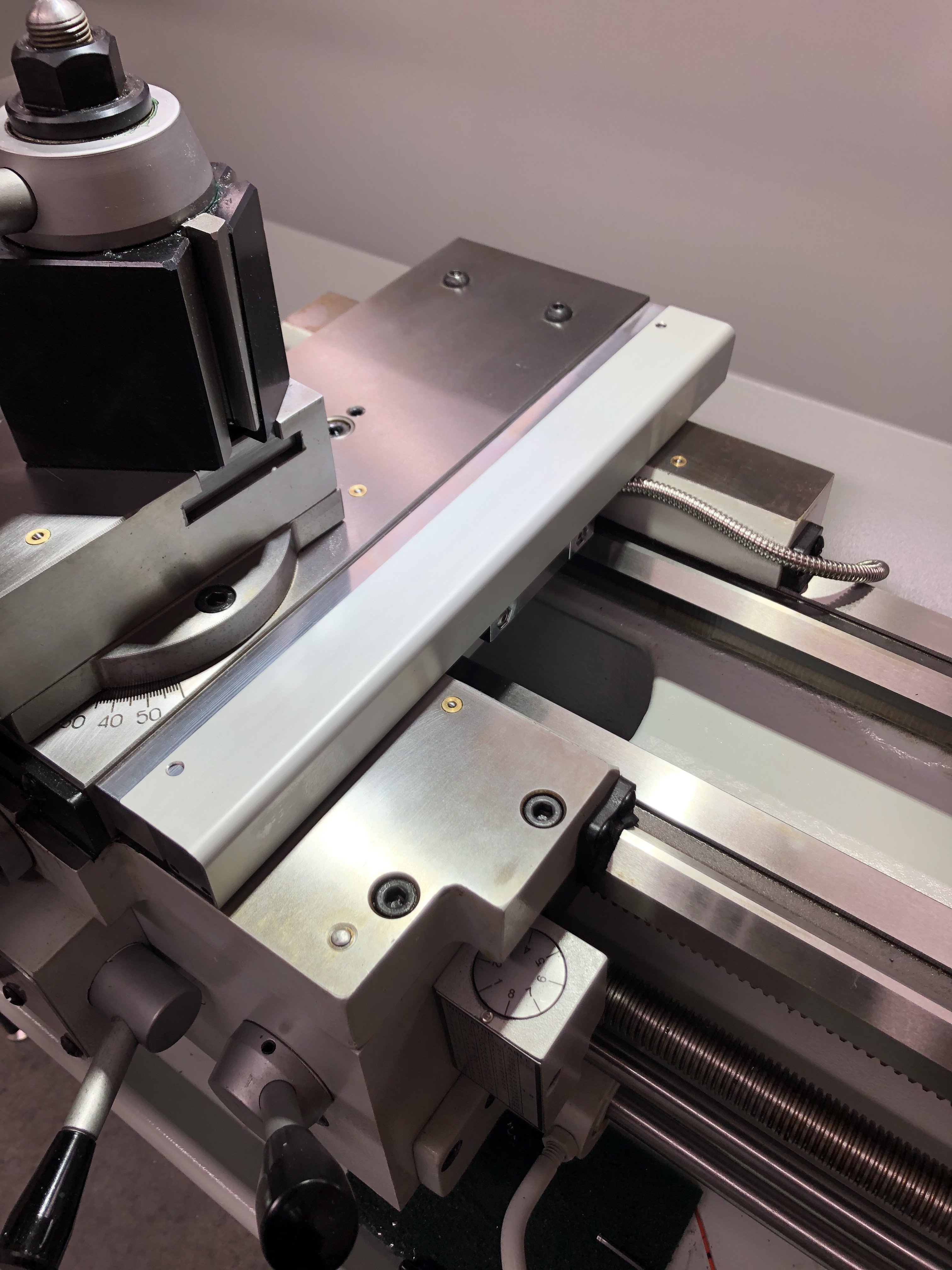

I am almost finished with the DRO install, man that cross slide install took way too long.

It's actually good to take on something like this as it sure improves my skills on my machines.

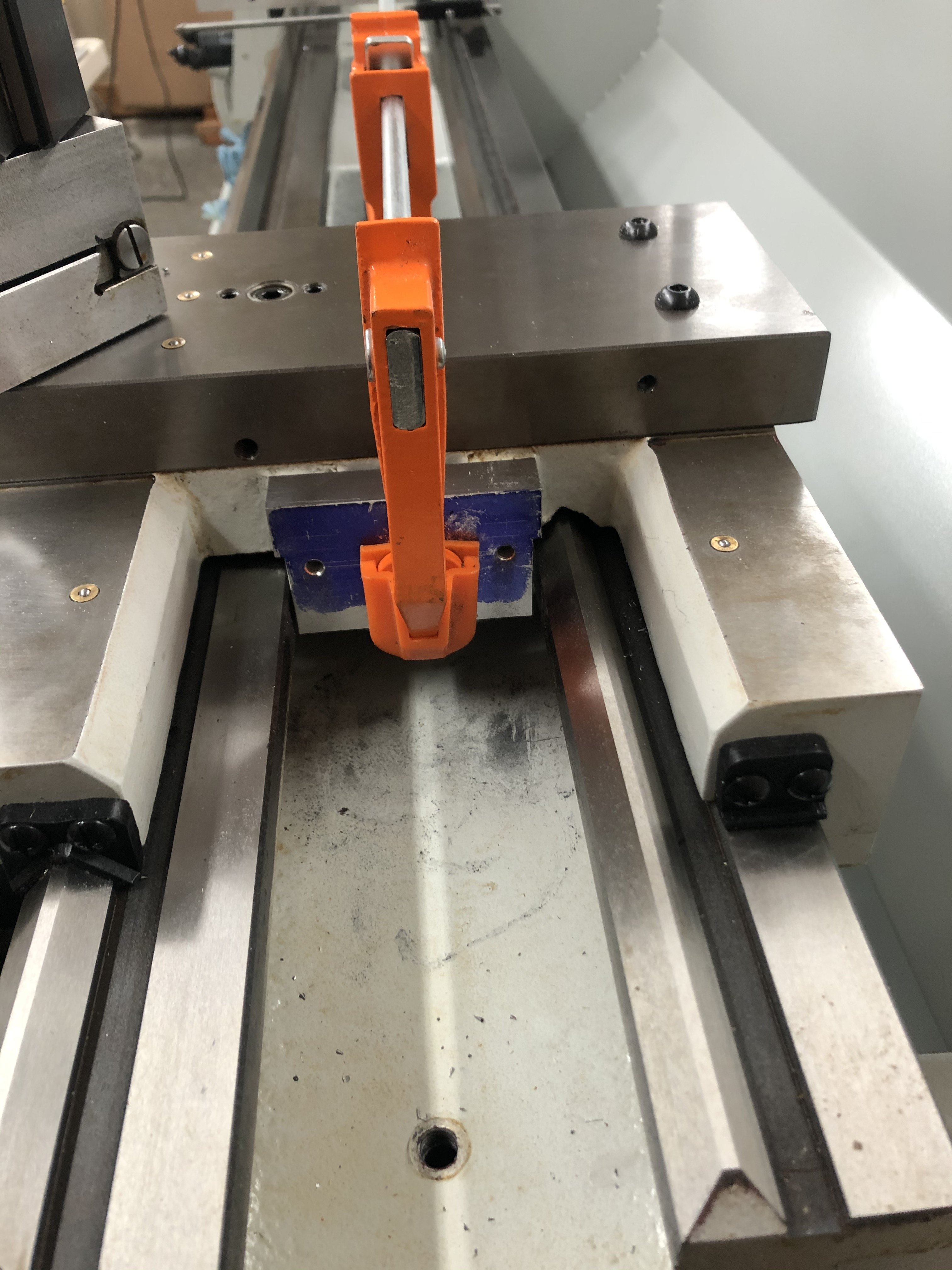

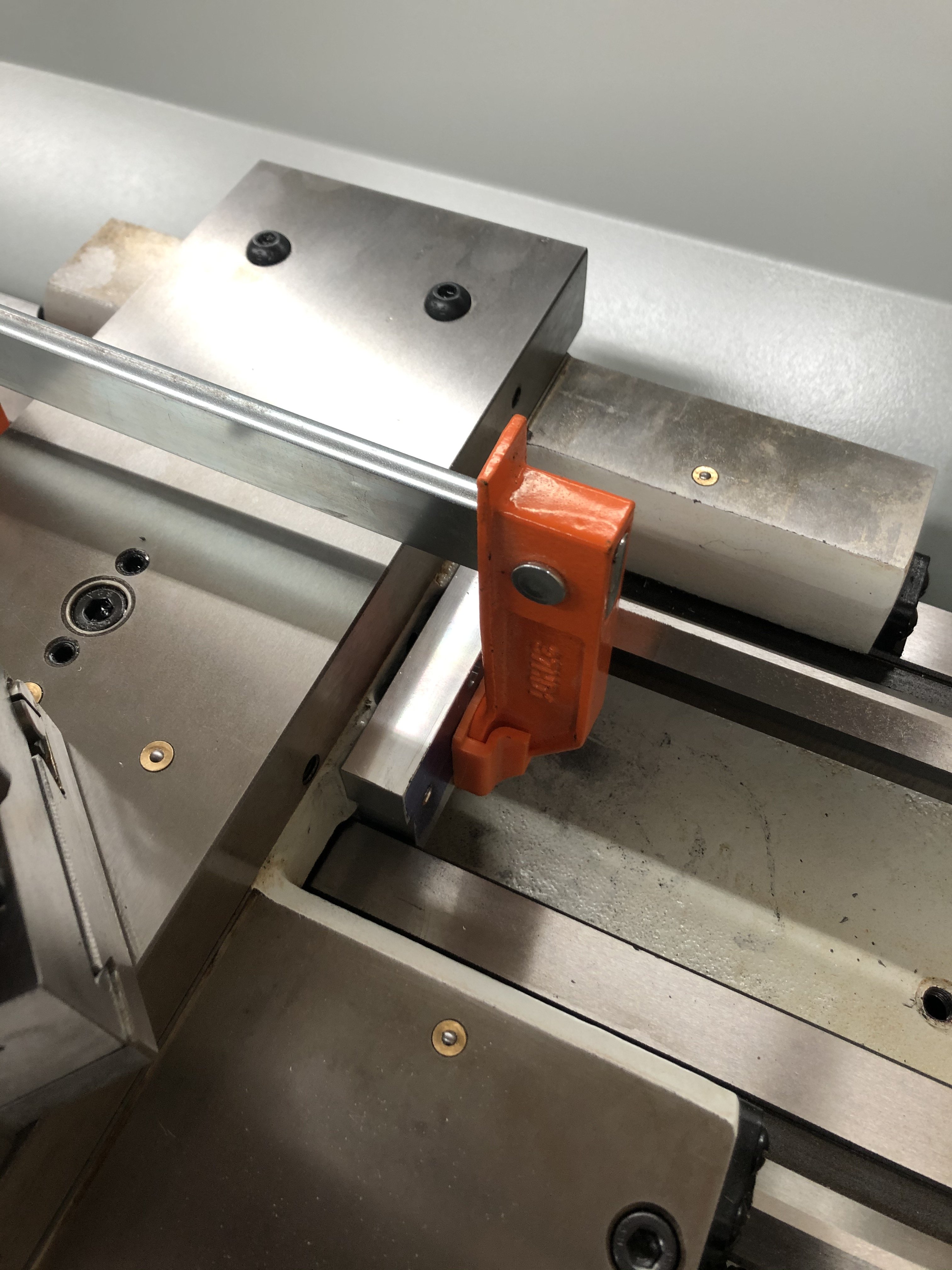

The little mounting bracket that holds the read head was a really challenging part to get right, the first one didn't work out, so I thought about the mounting process a little more and came up with a way to get it installed with a bit of adjustment built-in.

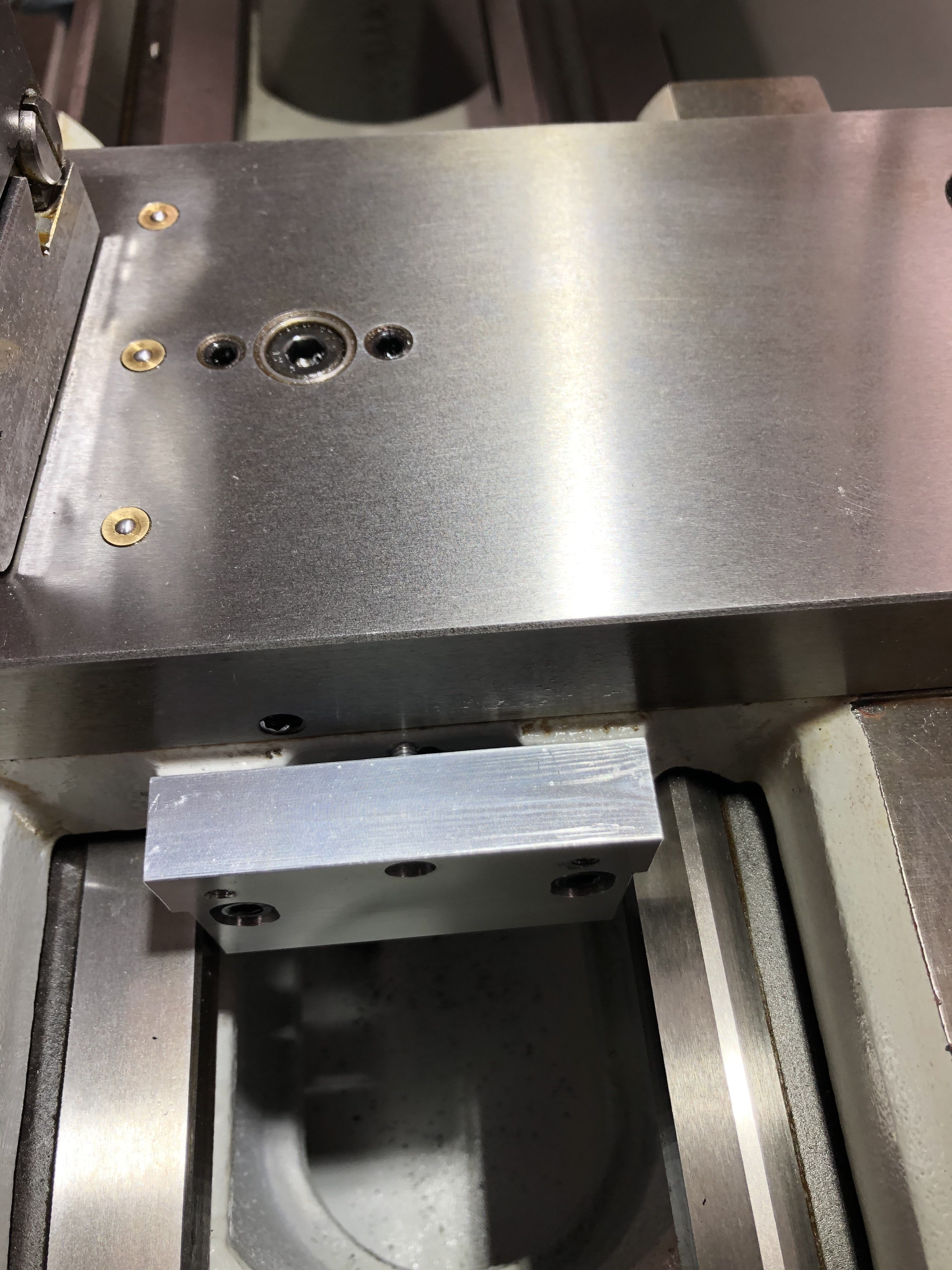

Also needed to make a long drill bit to reach these holes.

I then made Rev.2 and got a little aggressive with the face mill and made it too thin, so I needed to trim the spacer bracket to match, it was a little bit of 2 steps forward 1 back, it looks pretty good but then it's going to covered up with a cover, so much for my nice workmanship, it won't even be seen.

I installed a jack screw at the top center to adjust the plate as it had a slight tilt inwards at the top, probably would have been OK but might as well get it straight.

Testing the position of the cover, not sure if I'll use this one or make a custom made one.

I still need to add a hex bolt and make a cut away in the spacer to be able to lock the cross slide as others have done.

OK that's about all for now, I've still got a bit of work left on cable management and still need to cleanup my shop as it's a mess after all the milling and drilling today.

David.

It's actually good to take on something like this as it sure improves my skills on my machines.

The little mounting bracket that holds the read head was a really challenging part to get right, the first one didn't work out, so I thought about the mounting process a little more and came up with a way to get it installed with a bit of adjustment built-in.

Also needed to make a long drill bit to reach these holes.

I then made Rev.2 and got a little aggressive with the face mill and made it too thin, so I needed to trim the spacer bracket to match, it was a little bit of 2 steps forward 1 back, it looks pretty good but then it's going to covered up with a cover, so much for my nice workmanship, it won't even be seen.

I installed a jack screw at the top center to adjust the plate as it had a slight tilt inwards at the top, probably would have been OK but might as well get it straight.

Testing the position of the cover, not sure if I'll use this one or make a custom made one.

I still need to add a hex bolt and make a cut away in the spacer to be able to lock the cross slide as others have done.

OK that's about all for now, I've still got a bit of work left on cable management and still need to cleanup my shop as it's a mess after all the milling and drilling today.

David.

Last edited: