I've wanted to get a small mill for many years, initially I planned on a Grizzly G0704, then changed to a PM25 and considered many others along the way. But the procurement just kept slipping further and further out. I've been "getting by" with a Grizzly G0516 which is a combo 10x21 lathe and Mini Mill which I've had since 2003. The lathe is pretty capable but the Mini Mill is very limiting and the lathe cross slide is rather small and strange for a mill table. I'd like to get a better lathe, but I need the mill too so I really need to upgrade the mill first. Then maybe I'll be looking at lathes...

Recently I decided to just get on with ordering something, and was preparing to order a PM25 when the PM728 popped up. I waited and waited to see them in the field, but nothing was showing up, so finally I bit the bullet and made the order.

A few days before Christmas I got the tracking email and Saia LTL Freight had the package. There were a lot of tracking updates until it departed Chicago late in the week before Christmas, then all updates stopped. There were no estimates of delivery, no updates on where it was, just silence.

The day after Christmas my wife took the call saying it would be at the terminal in a day or two. Still no tracking updates, no estimates online. It hit the terminal early Friday morning and suddenly there were tracking updates online.

I had requested "hold at terminal", as I had done with the lathe years ago, as it works out better for me. We are on a cul-de-sac and big trucks are not happy delivering here, and my long sloping driveway is not fun to deal with. So I take a small flatbed trailer to the depot, they forklift the crate onto it, and I back it up wherever I want it. The trailer is much lower than my truck bed, and can be tilted if that is needed.

I made the trek to the Saia depot Friday afternoon and the very helpful people at the depot forked the crate on the pallet onto my trailer. They helped me remove the shipping pallet from under the crate, and I strapped it down thoroughly for the ride home. I screwed some 2x4's to the trailer bed in front to insure it would not slide forward during hard braking. I brought new straps and cranked them down till the crate was complaining so it would not be passing me on the freeway.

I used a hydraulic lift table to bring the mill from the trailer into the garage and up to workbench height and slide it onto a polyethylene cutting board which I can move easily. All the moving effort has been easy for two adults, no heavy lifting, just sliding an inch or so at a time. The cutting board wants to slide on the bench so I had to keep moving it back under the mill as we progressed. In summary the hydraulic lift table cart was excellent and made the job easy. A shop crane wasn't practical due to the gradient of the driveway and the low clearance under the workbench.

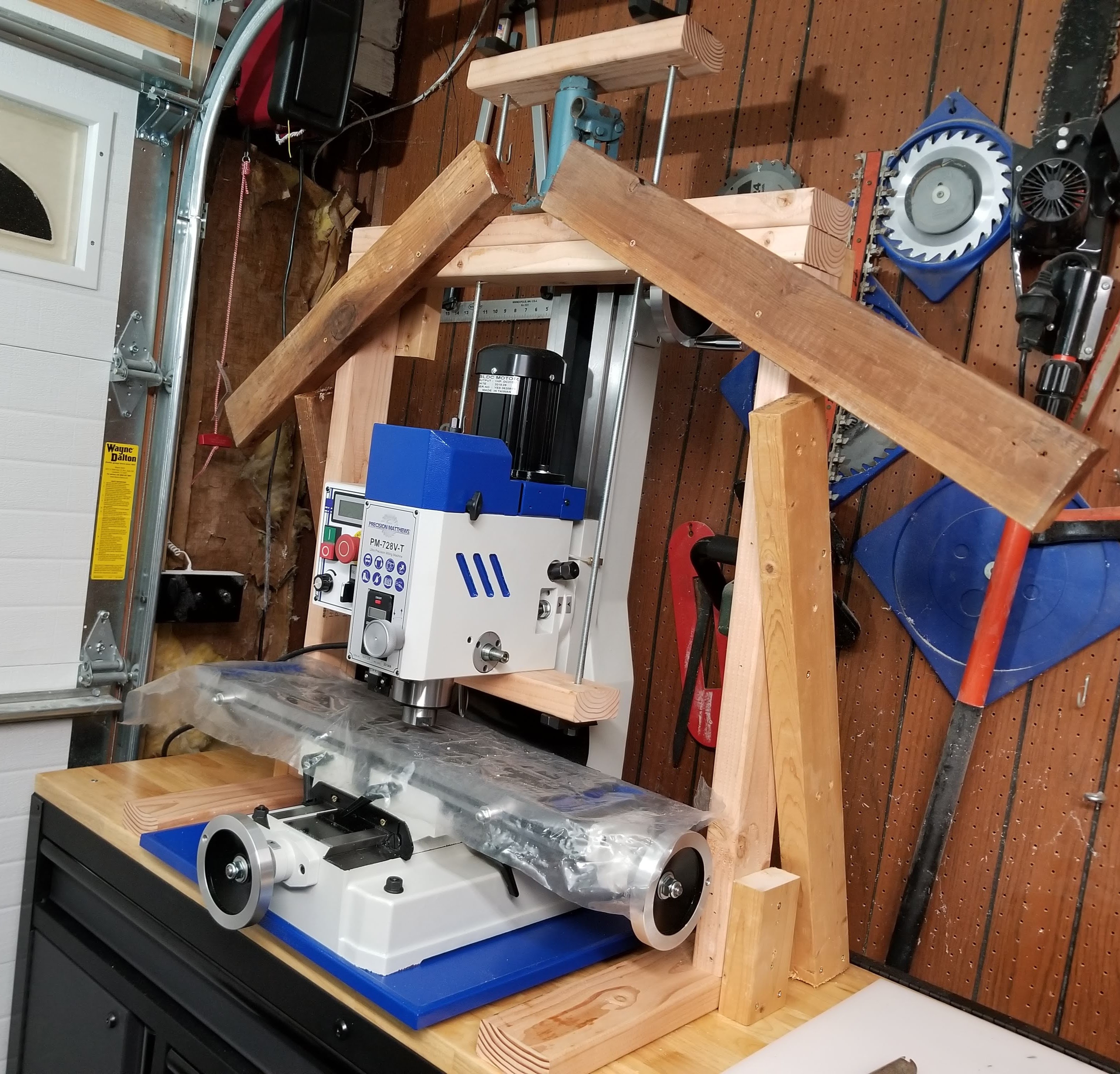

Then I built a temporary gantry and used a hydraulic jack and some threaded rods to lift it and position the drip tray underneath, an easy one man job. Here it has just landed:

So now it is in position on the mobile workbench with plenty of drawers to contain the tooling:

My plans are to use it manually for awhile as I prepare to convert it to CNC. This conversion is not going to be easy as there are no CNC kits available for the new mill. I may do a bootstrap conversion, making 3D printed parts and later converting to machined parts. I have been collecting a lot of the CNC controls parts for awhile so I have a Linux CNC system and Mesa boards as well as closed loop stepper motors and electronics in boxes. I've been doing 3D design and printing for a couple of years but this will be my first CNC conversion, which I've been reading about for years.

So it begins!

Recently I decided to just get on with ordering something, and was preparing to order a PM25 when the PM728 popped up. I waited and waited to see them in the field, but nothing was showing up, so finally I bit the bullet and made the order.

A few days before Christmas I got the tracking email and Saia LTL Freight had the package. There were a lot of tracking updates until it departed Chicago late in the week before Christmas, then all updates stopped. There were no estimates of delivery, no updates on where it was, just silence.

The day after Christmas my wife took the call saying it would be at the terminal in a day or two. Still no tracking updates, no estimates online. It hit the terminal early Friday morning and suddenly there were tracking updates online.

I had requested "hold at terminal", as I had done with the lathe years ago, as it works out better for me. We are on a cul-de-sac and big trucks are not happy delivering here, and my long sloping driveway is not fun to deal with. So I take a small flatbed trailer to the depot, they forklift the crate onto it, and I back it up wherever I want it. The trailer is much lower than my truck bed, and can be tilted if that is needed.

I made the trek to the Saia depot Friday afternoon and the very helpful people at the depot forked the crate on the pallet onto my trailer. They helped me remove the shipping pallet from under the crate, and I strapped it down thoroughly for the ride home. I screwed some 2x4's to the trailer bed in front to insure it would not slide forward during hard braking. I brought new straps and cranked them down till the crate was complaining so it would not be passing me on the freeway.

I used a hydraulic lift table to bring the mill from the trailer into the garage and up to workbench height and slide it onto a polyethylene cutting board which I can move easily. All the moving effort has been easy for two adults, no heavy lifting, just sliding an inch or so at a time. The cutting board wants to slide on the bench so I had to keep moving it back under the mill as we progressed. In summary the hydraulic lift table cart was excellent and made the job easy. A shop crane wasn't practical due to the gradient of the driveway and the low clearance under the workbench.

Then I built a temporary gantry and used a hydraulic jack and some threaded rods to lift it and position the drip tray underneath, an easy one man job. Here it has just landed:

So now it is in position on the mobile workbench with plenty of drawers to contain the tooling:

My plans are to use it manually for awhile as I prepare to convert it to CNC. This conversion is not going to be easy as there are no CNC kits available for the new mill. I may do a bootstrap conversion, making 3D printed parts and later converting to machined parts. I have been collecting a lot of the CNC controls parts for awhile so I have a Linux CNC system and Mesa boards as well as closed loop stepper motors and electronics in boxes. I've been doing 3D design and printing for a couple of years but this will be my first CNC conversion, which I've been reading about for years.

So it begins!