-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

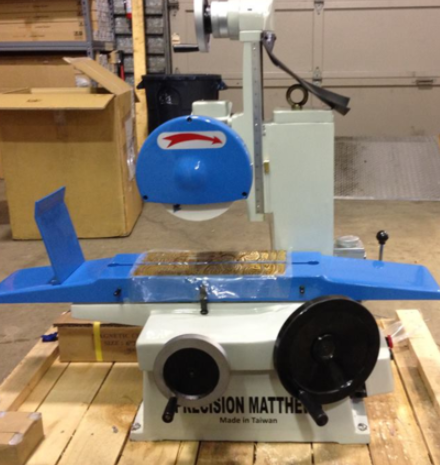

New PM Surface Grinder

- Thread starter JohnnyTK

- Start date

- Joined

- Nov 16, 2012

- Messages

- 5,596

Way back when, I remember Matt was checking about 5 different suppliers for this style of unit. He got samples, price quotes etc. The ones from China were dismissed from the running due to poor quality. The others were from Taiwan but, the price was too high given that he wanted them to use upgraded components. I'm interested in one of these and asked Matt the price today. It's a little over 3 grand but, he feels the quality is very good. I'm waiting for the exact specs. My guess, is it will be as good as a grinder in this size/weight range can get and will be on-par with the quality of his other flagship Taiwanese-made products. I suspect the one Matt has will far outshine my Frankenstein rebuild.

Enough of that until I decide if the price is worth it to me and after I see how well the KO-Lee rebuild works. I only need this for very small pieces these days.

On a technical note: If anyone has (or newly acquires) a surface grinder, you need to have dust control and really should be wearing a 90 or 95% particle mask. Just a couple minutes on the SG and you will taste metal in your mouth before you ever see the first signs of dust. The dust is a combination of metal and silicon/carbide abrasive material. -This is the stuff that causes nasty cases of bronchitis and long term, gives you lung cancer.

We get away with a lot on mills and lathes because the particles are big. Surface grinders.... The dust is practically invisible until you blow your nose and find yourself out of breath 3 days after using one.

Ray

Enough of that until I decide if the price is worth it to me and after I see how well the KO-Lee rebuild works. I only need this for very small pieces these days.

On a technical note: If anyone has (or newly acquires) a surface grinder, you need to have dust control and really should be wearing a 90 or 95% particle mask. Just a couple minutes on the SG and you will taste metal in your mouth before you ever see the first signs of dust. The dust is a combination of metal and silicon/carbide abrasive material. -This is the stuff that causes nasty cases of bronchitis and long term, gives you lung cancer.

We get away with a lot on mills and lathes because the particles are big. Surface grinders.... The dust is practically invisible until you blow your nose and find yourself out of breath 3 days after using one.

Ray

- Joined

- Jul 2, 2014

- Messages

- 7,594

Bill,So Bob: You are saying that Matt's new grinder is a cheap one that "grinds metal" and isn't very accurate? Have you even used one yet?

Hey Mike (zmotorsports): Do you have any idea what the price range on these new surface grinders will be?

All I am saying is that if I squint it looks like a lot of inexpensive import surface grinders out there that are known for being mediocre at best. That might be good enough for some users. I would in no way ever spend $3K for a SG built to that design, "premium quality" claims may or may not make it so. I have not used any surface grinder other than my B&S #2L. It is usually difficult to get a chance to run a surface grinder you do not own. I offer that chance to my buddies... I all I know about surface grinders other than mine is what I have read, and I read a lot.

- Joined

- Mar 21, 2013

- Messages

- 4,063

Bill,

All I am saying is that if I squint it looks like a lot of inexpensive import surface grinders out there that are known for being mediocre at best. That might be good enough for some users. I would in no way ever spend $3K for a SG built to that design, "premium quality" claims may or may not make it so. I have not used any surface grinder other than my B&S #2L. It is usually difficult to get a chance to run a surface grinder you do not own. I offer that chance to my buddies... I all I know about surface grinders other than mine is what I have read, and I read a lot.

Fair enough.

I'll reserve judgement until I talk to Matt and find out more about it.

- Joined

- Dec 3, 2014

- Messages

- 778

3-4 grand in a new surface grinder gets you a bucket of compromises, that is not opinion, its fact. It does not matter if that machine came from mainland or Taiwan its a poor platform for surface grinding, nothing rigid about that design, it was built to be lightweight and inexpensive. Good surface finish requires rigidity, rigidity, rigidity. Bob Korves nailed it when he said it a mediocre at best design. The sheet metal stand alone speaks volumes. If surface finish is of little concern this machine might be of interest but I would steer any of my friends in a different direction.

A

Alan H.

Forum Guest

Register Today

DB, share some more insights with us.

I hear your opinion on the stand. But looks like some significant metal above the stand.

I hear your opinion on the stand. But looks like some significant metal above the stand.

- Joined

- Jul 2, 2014

- Messages

- 7,594

The other thing I do not like about the generic machine design as viewed in post 1 and post 16 is its inability to support coolant, unless you allow it to be total loss on the floor. Surface grinding without some sort of liquid coolant is a dusty and unhealthy mess, makes it easy to burn the metal, tends to warp the workpiece, changes the dimensions, and leaves a poor finish. I am sure the machine has its usefulness, but it is unlikely it can fill common expectations of what a surface grinder should do in the shop. To be fair, many big, heavy, old, and worn out surface grinders fit into the same category. I truly hope that Matt can bring to market a useful SG at an affordable cost, there is a real need for one.

- Joined

- Nov 16, 2012

- Messages

- 5,596

After my inquiry, Matt sent an email to mention this unit was the best combination of quality and price he could find. In his words (and this should come as no surprise) it will not perform like a $10,000 grinder. Apparently, he's been keeping a few in stock for a few years now but, most are sold on a special-order basis. He's gotten no complaints at all about them in the last few years. He does not think these will sell like hotcakes. FWIW, MSC sells the same unit and charges nearly $1000 more for it.

As for me... I happen to notice that Tormach sells a CNC version of this for just under $4000.

At that price point, I can all but certainly guarantee it is a converted Chinese unit. The video shows the quality of the finished part which is very good.

As many of you know, I'm doing a surface grinder conversion of an old KO Lee grinder. I just did the first test yesterday and the results were surprising. https://www.hobby-machinist.com/threads/ko-lee-cutter-grinder-revamp.65608/

The design decisions made in that spindle are not outlined in that thread but, since the KO Lee unit only weighs about 150lbs I knew another approach had to be taken. It seems to be working so far. BTW, in the future when I use the grinder (and my procedures when I had the full-size unit) was to use kool mist to keep dust under control. Paper towels bunched-up at the base of the mag chuck absorbs all the run-off.

Ray

As for me... I happen to notice that Tormach sells a CNC version of this for just under $4000.

At that price point, I can all but certainly guarantee it is a converted Chinese unit. The video shows the quality of the finished part which is very good.

As many of you know, I'm doing a surface grinder conversion of an old KO Lee grinder. I just did the first test yesterday and the results were surprising. https://www.hobby-machinist.com/threads/ko-lee-cutter-grinder-revamp.65608/

The design decisions made in that spindle are not outlined in that thread but, since the KO Lee unit only weighs about 150lbs I knew another approach had to be taken. It seems to be working so far. BTW, in the future when I use the grinder (and my procedures when I had the full-size unit) was to use kool mist to keep dust under control. Paper towels bunched-up at the base of the mag chuck absorbs all the run-off.

Ray

- Joined

- Mar 21, 2013

- Messages

- 4,063

The other thing I do not like about the generic machine design as viewed in post 1 and post 16 is its inability to support coolant, unless you allow it to be total loss on the floor. Surface grinding without some sort of liquid coolant is a dusty and unhealthy mess, makes it easy to burn the metal, tends to warp the workpiece, changes the dimensions, and leaves a poor finish. I am sure the machine has its usefulness, but it is unlikely it can fill common expectations of what a surface grinder should do in the shop. To be fair, many big, heavy, old, and worn out surface grinders fit into the same category. I truly hope that Matt can bring to market a useful SG at an affordable cost, there is a real need for one.

We had a small SG in my mentor's pistolsmithing business and we used to splash a little coolant on the part before doing each pass/series of passes, and then again before the next. Made for a better finish and kept the part cooler.

If I were to ever have one of these (I know a couple of 'smiths that have the Grizz offering) I'd want to put a Fogbuster on it.