- Joined

- Jan 24, 2015

- Messages

- 239

Dear All,

I ordered a PM25 with the DRO and X axis power feed in March, I think. It was delivered in late April, and it took me until mid May to get it installed in my shop. This machine is to be a significant upgrade from my Sherline mill.

I chose the PM25 because my shop is a very small (10' x 20') Tuff Shed (the Mannex, an annex to the garage for a man-my wife's name for the shop), with a floor that can only handle 60 lbs/sq ft of weight. Anything larger, and I would be looking at some severe floor sag. I could have modified the shop floor to take more weight, but I still would have a space problem. So, after much comparison among the smaller bench mills, I chose the PM25.

It arrived in the typical crate, which was delivered to my garage. The crate was opened, stuff inspected, and there it sat until I could get together with my brother to move it into the shop. Getting it from my garage to the shop was funny and challenging. And I have no photos. Needless to say I was icing my back for the next three days. But no animals were harmed.

We leveled the mill with some shims and my precision level, and then called it a night. The next day I fired up the lathe to check the electronicals, and found that I had one speed, high. It did not matter what position the potentiometer was placed in, it ran at max speed. I also found out that the drill chuck I ordered was not R8, which I still have to return.

I called PM, and after some monkeying around it was determined that either the potentiometer or the control board were fubar. PM then ordered a new board from the factory in China, and I left for a road trip to WI and MN. When I got back, the new board and a new potentiometer were waiting. I installed said parts, and the freaking thing worked!

My first modification of the machine was to install a tramming aid. I think I might install a second one at the bottom of head to make things more symmetrical. I also installed the X axis power feed, but can't figure out how to install the limit switch. For now, I have no limit switch as I ponder the problem.

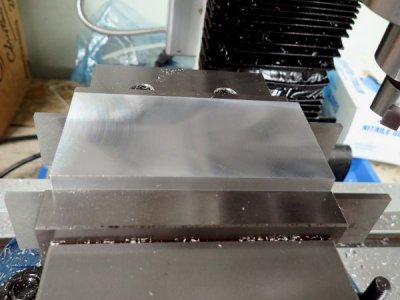

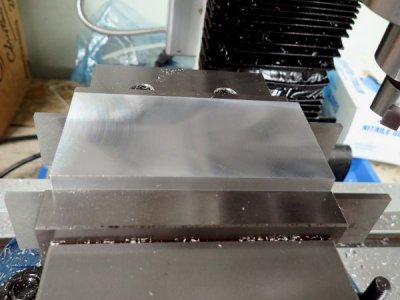

I am now tramming and so forth. I have also made some preliminary fly cuts.

I ordered a PM25 with the DRO and X axis power feed in March, I think. It was delivered in late April, and it took me until mid May to get it installed in my shop. This machine is to be a significant upgrade from my Sherline mill.

I chose the PM25 because my shop is a very small (10' x 20') Tuff Shed (the Mannex, an annex to the garage for a man-my wife's name for the shop), with a floor that can only handle 60 lbs/sq ft of weight. Anything larger, and I would be looking at some severe floor sag. I could have modified the shop floor to take more weight, but I still would have a space problem. So, after much comparison among the smaller bench mills, I chose the PM25.

It arrived in the typical crate, which was delivered to my garage. The crate was opened, stuff inspected, and there it sat until I could get together with my brother to move it into the shop. Getting it from my garage to the shop was funny and challenging. And I have no photos. Needless to say I was icing my back for the next three days. But no animals were harmed.

We leveled the mill with some shims and my precision level, and then called it a night. The next day I fired up the lathe to check the electronicals, and found that I had one speed, high. It did not matter what position the potentiometer was placed in, it ran at max speed. I also found out that the drill chuck I ordered was not R8, which I still have to return.

I called PM, and after some monkeying around it was determined that either the potentiometer or the control board were fubar. PM then ordered a new board from the factory in China, and I left for a road trip to WI and MN. When I got back, the new board and a new potentiometer were waiting. I installed said parts, and the freaking thing worked!

My first modification of the machine was to install a tramming aid. I think I might install a second one at the bottom of head to make things more symmetrical. I also installed the X axis power feed, but can't figure out how to install the limit switch. For now, I have no limit switch as I ponder the problem.

I am now tramming and so forth. I have also made some preliminary fly cuts.