I put the prop shaft together this morning, drilled and bored the 11mm stainless, only took 3 tries to get it right... the rest was pretty strait forward, run a die over the end to thread it and drill a cross hole for the drive pin for the prop.

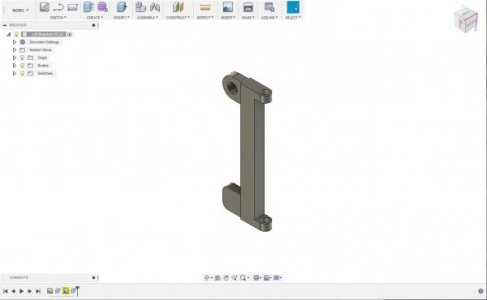

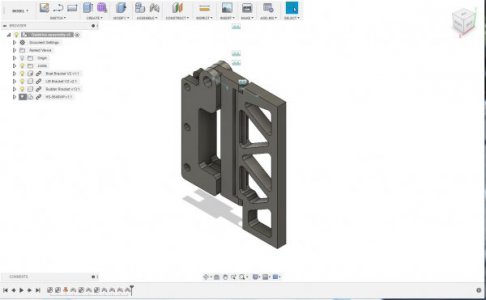

here is the motor mounted with the lovejoy coupler installed

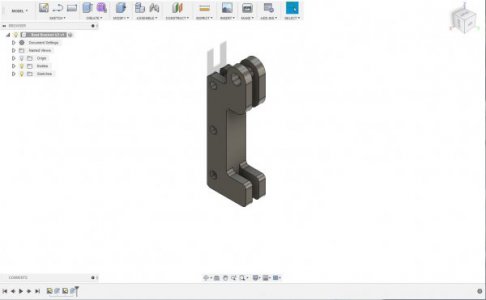

the tail section with the bearings and seal in place.

shaft in.

Prop installed.

Motor on, it goes together really easy.

The wires will come out through a hole into the shaft coming down to the motor from the boat then the nose cone can go back on.

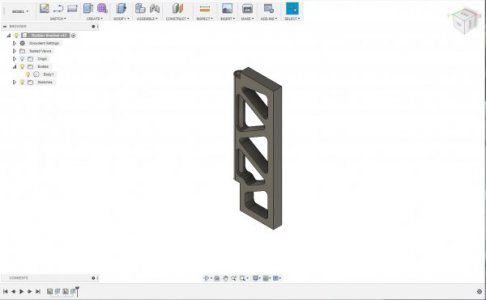

I got a foot of aero tube for the shaft,

I don't have a TIG welder so I'm going to build a jig to hold it all together and take it to someone to weld the shaft and scag on.

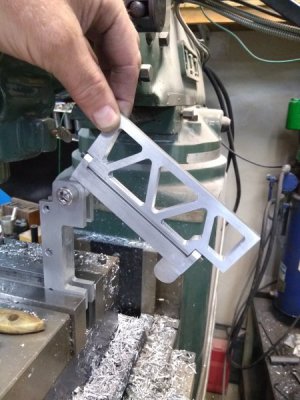

I'm also working on the mounting bracket for the back of the Kayak so that's coming up soon.

I'm off to get more sandpaper so I can finish the polishing and drill the holes for the wires and pin wrench.

Thanks for all the encouraging words.