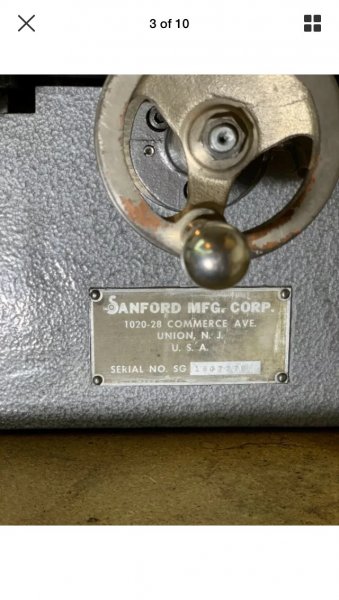

I just picked up a Sanford SG-10 surface grinder. I purchased it off of Ebay and made the 10 hour round trip from Philadelphia to Charlottsville Virginia 2 weeks ago to pick it up. Its in good shape for its age but needs a little bit to get it going.

The machine does run as you can see by the ground surface of the table and the previous owner had ground a few parts with it. I still need to get a mag chuck and it looks like I will be getting a 4x7 permanent magnetic chuck from Grizzly.

I need a few things to get it going and I was wondering if anyone can help. I am going to highlight and underline my questions so everyone doesn’t have to read everything as I tend to go into to much detail.

First, I am in need of the OD dimensions of the driver and driven flat pulleys. The original pulleys are shot. Both of them have excessive wear to the point that the belt will not even make contact in the center of the spindle pulley, just the outer edges. The motor pulley has definitely been replaced at one time or another but the spindle pulley is definitely original. Judging by the worn ridges on the face of the spindle pulley it appears as though its original diameter was right around 1”. The motor pulley is 1.5”. If no-one is able to provide me with the dimensions maybe someone could help me figure out what size the pulleys are supposed to be based off of the motor speed and the speed the spindle should be running at? From what I have gathered the motors all run at the common 3450rpm. According to lathes.co.uk the spindle speed should 5500rpm. I have used online pulley calculators and while they get you close they dont get it close enough for me. what formula do I need?

I am also under the assumption that flat belts need at least 1 pulley to be convex so that the belt tracks straight and does not run off of the pulley. Do both pulleys need to be convex? I have searched for the correct radius for the size range of pulleys I need but everywhere I look seems to give me different dimensions. Some have said that it is OK to have the center 1/3 flat and the other 2/3 with a 1 degree taper. I’ve thought about doing this but I don’t know if this will be good enough for a belt running at this speed.

Do I need to have an outer guide on one or both of the pulleys? The factory spindle pulley had a guide but I’m not sure if the motor pulley had a guide. Is it even necessary? I have found a picture of a factory spindle pulley but I have not been able to find a picture of the motor pulley. The spindle pulley in the photo from lathes.co.uk is also definnitly worn as well but it looks useable. As for the width of the belt I have 2 options I can go with. The original belt appears to have been 1/2”, at least thats what was on it when I got it. I found a vacuum cleaner belt that matches the factory belt. It is 17.5” long and a 1/2” wide. It appears to be decently made and a member from the Facebook Youtube group recommended this belt and says he uses it on his Sanford SG without any issues. My other option is a Sopko belt which I just received today. It is also 17.5” long but the width is wider at 5/8”. The belt is a Gates belt and is a special wooven fabric made for high speed. I am almost certain I will be making the pulleys to fit the 5/8” wide Sopko belt. They have a very good reputation of making long lasting smooth running belts. If anyone has any other thoughts or can give me their opinion as to why I should use one belt over the other. The vacuum cleaner belt was $6 for 2 and the Sopko was $15 plus $16 shipping.

There are 2 more things that I will need to keep it going in the future.

First, I need a source for 4” diameter grinding wheels for a 1/2” diameter arbor. The factory wheels were 3/8” wide but I can make do with 1/2” wide wheels if thats all I can find. I’ve seen on other forums it recommended to use tool and cutter grinder wheels but from the research I have done so far they typically use a smaller arbor and the OD is usually 3-3.5”.

Is there a way to modify the arbor diameter or does anyone know of a supplier who will make the size wheels I need? I would like to have a few wheels on hand for different materials but I don’t want to spend a small fortune for a hobby machine.

Lastly I need to make a shield that will cover the spindle’s Y-axis leadscrew and the column ways that the spindle bears on. From what I gather the left and right pieces that wrapped around the sides of the column were originally made from cast aluminum and the shield that covered the spindle was sheetmetal and it rode up and down with the spindle. There were 3 pieces with long slots the width of the spindle housing and they worked similar to the way the covers for the Z-axis work. It’s actually really complicated to explain since I do not know the correct terms for the parts. The pictures I have found online do not really show how the covers work or are constructed. I’ve yet to find a picture of the actual shields themselves. If anyone has a picture of the shields off of the column it would be greatly appreciated or if they could explain how they worked I could then make my own.

I would like to add that in my search for parts I discovered that the Axis of a surface grinder is not the same of your typical milling machine. On a surface grinder the vertical column that the spindle travels on is the Y-axis, not the Z-axis. Not that this really matters for someone to be able to help me but I figured I would mention it before I get corrected. Maybe I’m totally wrong and it is identical to a milling machine but I figured I’d try and use the correct axis so there is no confusion. Hell, I’m confused just writing this!

If anyone has any questions for me or would like to see a particular part of the machine please let me know. I would be glad to take pictures and answer any questions anyone might have. There does not appear to be a lot of information on these forums in regard to this particular machine and I would like to help change that. If anyone knows of a thread that is in these forums in regard to my questions please let me know and I will try and find it but my past searches have not given me anything I can use.

I have attached a few pictures of the machine. Some of the pictures are from the Ebay listing and I felt it was OK to use them because the machine has not changed since I took possession of it. I have also attached a few pictures of the measurements I took of the worn out pulleys.

I know this is a lot of text to read through. If anyone can offer me any advice they have I would greatly appreciate it. I will update my progess here and once I get it going I will snap some photos or maybe a video of grinding a part.

Just in case you’re curious, the history of Sanford benchtop surface grinders can be found below. These were originally manufactured in New Jersey about a half hour from me in a garage.

http://www.lathes.co.uk/sanford/

The machine does run as you can see by the ground surface of the table and the previous owner had ground a few parts with it. I still need to get a mag chuck and it looks like I will be getting a 4x7 permanent magnetic chuck from Grizzly.

I need a few things to get it going and I was wondering if anyone can help. I am going to highlight and underline my questions so everyone doesn’t have to read everything as I tend to go into to much detail.

First, I am in need of the OD dimensions of the driver and driven flat pulleys. The original pulleys are shot. Both of them have excessive wear to the point that the belt will not even make contact in the center of the spindle pulley, just the outer edges. The motor pulley has definitely been replaced at one time or another but the spindle pulley is definitely original. Judging by the worn ridges on the face of the spindle pulley it appears as though its original diameter was right around 1”. The motor pulley is 1.5”. If no-one is able to provide me with the dimensions maybe someone could help me figure out what size the pulleys are supposed to be based off of the motor speed and the speed the spindle should be running at? From what I have gathered the motors all run at the common 3450rpm. According to lathes.co.uk the spindle speed should 5500rpm. I have used online pulley calculators and while they get you close they dont get it close enough for me. what formula do I need?

I am also under the assumption that flat belts need at least 1 pulley to be convex so that the belt tracks straight and does not run off of the pulley. Do both pulleys need to be convex? I have searched for the correct radius for the size range of pulleys I need but everywhere I look seems to give me different dimensions. Some have said that it is OK to have the center 1/3 flat and the other 2/3 with a 1 degree taper. I’ve thought about doing this but I don’t know if this will be good enough for a belt running at this speed.

Do I need to have an outer guide on one or both of the pulleys? The factory spindle pulley had a guide but I’m not sure if the motor pulley had a guide. Is it even necessary? I have found a picture of a factory spindle pulley but I have not been able to find a picture of the motor pulley. The spindle pulley in the photo from lathes.co.uk is also definnitly worn as well but it looks useable. As for the width of the belt I have 2 options I can go with. The original belt appears to have been 1/2”, at least thats what was on it when I got it. I found a vacuum cleaner belt that matches the factory belt. It is 17.5” long and a 1/2” wide. It appears to be decently made and a member from the Facebook Youtube group recommended this belt and says he uses it on his Sanford SG without any issues. My other option is a Sopko belt which I just received today. It is also 17.5” long but the width is wider at 5/8”. The belt is a Gates belt and is a special wooven fabric made for high speed. I am almost certain I will be making the pulleys to fit the 5/8” wide Sopko belt. They have a very good reputation of making long lasting smooth running belts. If anyone has any other thoughts or can give me their opinion as to why I should use one belt over the other. The vacuum cleaner belt was $6 for 2 and the Sopko was $15 plus $16 shipping.

There are 2 more things that I will need to keep it going in the future.

First, I need a source for 4” diameter grinding wheels for a 1/2” diameter arbor. The factory wheels were 3/8” wide but I can make do with 1/2” wide wheels if thats all I can find. I’ve seen on other forums it recommended to use tool and cutter grinder wheels but from the research I have done so far they typically use a smaller arbor and the OD is usually 3-3.5”.

Is there a way to modify the arbor diameter or does anyone know of a supplier who will make the size wheels I need? I would like to have a few wheels on hand for different materials but I don’t want to spend a small fortune for a hobby machine.

Lastly I need to make a shield that will cover the spindle’s Y-axis leadscrew and the column ways that the spindle bears on. From what I gather the left and right pieces that wrapped around the sides of the column were originally made from cast aluminum and the shield that covered the spindle was sheetmetal and it rode up and down with the spindle. There were 3 pieces with long slots the width of the spindle housing and they worked similar to the way the covers for the Z-axis work. It’s actually really complicated to explain since I do not know the correct terms for the parts. The pictures I have found online do not really show how the covers work or are constructed. I’ve yet to find a picture of the actual shields themselves. If anyone has a picture of the shields off of the column it would be greatly appreciated or if they could explain how they worked I could then make my own.

I would like to add that in my search for parts I discovered that the Axis of a surface grinder is not the same of your typical milling machine. On a surface grinder the vertical column that the spindle travels on is the Y-axis, not the Z-axis. Not that this really matters for someone to be able to help me but I figured I would mention it before I get corrected. Maybe I’m totally wrong and it is identical to a milling machine but I figured I’d try and use the correct axis so there is no confusion. Hell, I’m confused just writing this!

If anyone has any questions for me or would like to see a particular part of the machine please let me know. I would be glad to take pictures and answer any questions anyone might have. There does not appear to be a lot of information on these forums in regard to this particular machine and I would like to help change that. If anyone knows of a thread that is in these forums in regard to my questions please let me know and I will try and find it but my past searches have not given me anything I can use.

I have attached a few pictures of the machine. Some of the pictures are from the Ebay listing and I felt it was OK to use them because the machine has not changed since I took possession of it. I have also attached a few pictures of the measurements I took of the worn out pulleys.

I know this is a lot of text to read through. If anyone can offer me any advice they have I would greatly appreciate it. I will update my progess here and once I get it going I will snap some photos or maybe a video of grinding a part.

Just in case you’re curious, the history of Sanford benchtop surface grinders can be found below. These were originally manufactured in New Jersey about a half hour from me in a garage.

http://www.lathes.co.uk/sanford/