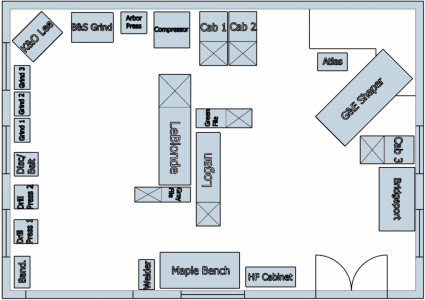

Based on the current inventory, I monkeyed around in Sketchup and came up with the layout below. The Xed out areas are the additional clear space(s) I need to open drawers, get in drawbars, etc....

View attachment 398215

The maple woodworking bench is currently a dumping/sorting ground, will eventually get replaced with a homemade metal bench I imagine and the wooden bench will go upstairs.

View attachment 398227

I'll be putting the 1959 BP J-head, Logan, Leblond and B&S grinder up on 4-5" riser feet; but for the time being, 4x4s are cribbing the mill up to a really nice working height.

View attachment 398226

Shaper corner. 1950 Atlas 7b and a 1954 G&E 20-24" Industrial. The rotary phase converter is on a small wooden pallet beneath the stairs (no pictures, strangely enough).

View attachment 398225

This spring/summer I'm planning pouring a pad off of the back of the shop, and putting up a shed roof to shelter the Kubota (and some material racks I have for stock). The air compressor and rotophase are both likely to be moving out there too. The back wall will get a little less-crowded when the compressor moves out. The downstairs 24K BTU mini-split head unit is in this picture; there's a 12K head on the 2nd floor. I over-bought a little and got a 4-zone outdoor unit, so if the 24K isn't up to the task (it should be, it's been running all winter through the really cold spells and surprisingly seemed way more than enough heating).

View attachment 398224

1949 LeBlond Dual Drive 15x40, and the 1960 Logan model 1957H 11x36 (blue) in the background

View attachment 398223

Dake 1 3/4 press and a nice Swiss Weidmann press

View attachment 398222

1975ish KO Lee model BA960 tool & cutter grinder, and a 1928 Brown & Sharpe #2 surface grinder

View attachment 398221

Delta triple-duty grinder, Clausing variable speed drill press, a Taiwanese Orbit drill press (with a tapping head), Baldor grinder, and a Delta carbide grinder (behind the straw mat)

View attachment 398220View attachment 398219