- Joined

- Dec 29, 2013

- Messages

- 631

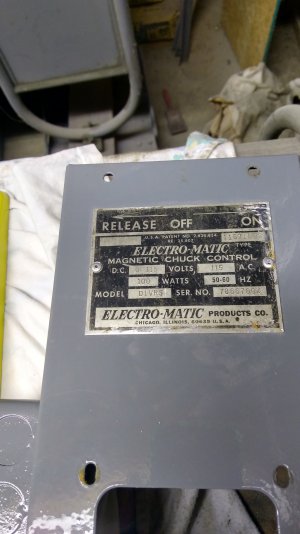

A hint worth repeating is when Your part is held by a magnetic chuck,the last thing to do before starting to grind it is to grab ahold of it and try to move it. You might never have another chance to see if it is held solidly. The first piece I ground on MY surface grinder was a tool bit. Stellite. Stellite is not magnetic. Almost launched that one! Be careful