- Joined

- Aug 1, 2016

- Messages

- 25

Don't post much, but have been reading the forums for a bit. Keep meaning to post some stuff about my garage and tools but never seem to have time.

Anyway, have been setting up a small basement machine shop. I had previously acquired a Harbor Freight micro mill (basically Sieg X1 mill/drill) and have some tooling for it. Other basic tools I have, or have restored: Rockwell/Delta 14" wood/metal band saw, HF 4x6" horizontal band saw, Rockwell/Delta 6+6 Drill Press, Hobart 140 MIG welder, and some misc wood working stuff.

It was a used machine and was a entry into the metal working arena. I had been looking for a lathe, and this popped up nearby.

At first I thought it was a regular old South Bend 9C since it has change gears. Once I did some more research I realized this was a much earlier lathe. The serial number dates it to 1928 and this is a "Junior" 9" lathe.

Its definitely not like-new, but it seems to have been at least somewhat cared for. Decent paint, covered in oil still, and with a small bit of tooling and what I believe is the complete set of change gears. I still need to inventory all of the gears to make sure all are there.

It is so old that it was sold with the ceiling mount line-shaft transmission, rather than with an electric motor. The lathe came with a very old Bendix washing machine motor, obviously not original. The line-shaft transmission is interesting, it has two large flat belt pulleys to link this into the wider shop belt system, and a left-right shifter mechanism that pushes a cone over, engages a pawl and causes a friction clutch type mechanism to expand inside of the pulley, which when engaged causes the inner shaft to rotate and therefore turn the three step pulley and engage the lathe.

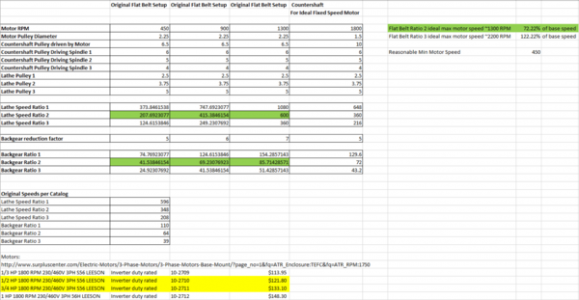

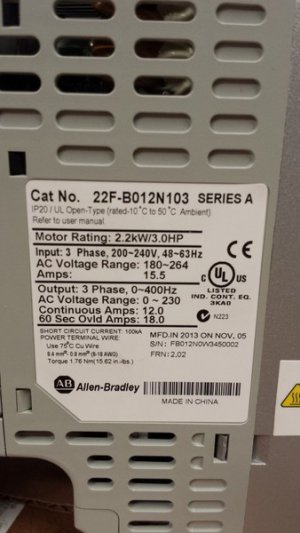

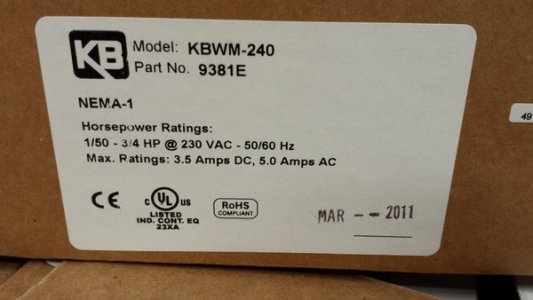

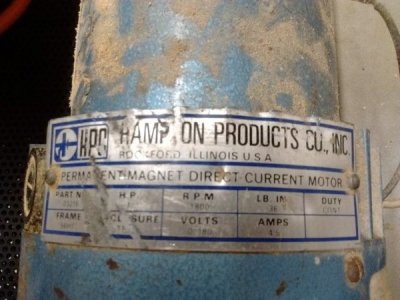

I am not planning on reusing the motor supplied, will likely either find a 3 phase motor and add VFD or find a treadmill/DC motor and controller. I work with VFDs a lot for work and am comfortable on the electronics side of either solution. However I will need to figure out a pulley and belt solution to get the right speed ranges.

There is definitely some damage on the lathe from prior mishaps. The chuck has clearly been dropped a few times, although only the inner parts of the lathe bed seem damaged, not the outer ways. This Junior lathe has a wider bed than the newer "Workshop" lathes I believe, being derived from the earlier 10" lathe.

The compound has also clearly been crashed into the chuck a number of times. One tooth is missing on the back gear. I hope that with just one tooth out, it will still run smooth enough. The main large hand wheel on the apron is a bit wobbly, but otherwise the controls seem tight enough with what appears to be reasonable back lash.

I don't see any evidence of a ridge on the ways, and only minor knicks on the actual ways themselves.

Otherwise the lathe came with a few bits of tooling.

At some point someone cut a drum in half and welded some angle iron together to make a removable chip pan.

I definitely am not a lathe expert, having only run one a few times.

Today I degreased and cleaned up the cast iron legs and got a coat of Rustoleum primer on them. It appears the lathe has been repainted standard Rustoleum Smoke Gray so I will be doing the same on the legs and chip pan to match.

So my overall to-do:

1. Get legs painted

2. Figure out leveling feet solution

3. Remount lathe to legs and get level

4. Figure out motor/drive belt and pulleys

5. Get appropriate oils and grease

6. Test the lathe! Was not able to run under power so next I will need to evaluate what I actually have.

If all seems well once under power I will then start trying to do more with it. I would like to get a drill chuck for the tail stock, need to learn to grind some tooling and just start learning the lathe.

It wasn't quite what I was looking for (was trying for a Model A with QC box) but the price was quite right, being approximately the cost of a used HF 7x10 lathe.

Thanks for looking!

Bill

Anyway, have been setting up a small basement machine shop. I had previously acquired a Harbor Freight micro mill (basically Sieg X1 mill/drill) and have some tooling for it. Other basic tools I have, or have restored: Rockwell/Delta 14" wood/metal band saw, HF 4x6" horizontal band saw, Rockwell/Delta 6+6 Drill Press, Hobart 140 MIG welder, and some misc wood working stuff.

It was a used machine and was a entry into the metal working arena. I had been looking for a lathe, and this popped up nearby.

At first I thought it was a regular old South Bend 9C since it has change gears. Once I did some more research I realized this was a much earlier lathe. The serial number dates it to 1928 and this is a "Junior" 9" lathe.

Its definitely not like-new, but it seems to have been at least somewhat cared for. Decent paint, covered in oil still, and with a small bit of tooling and what I believe is the complete set of change gears. I still need to inventory all of the gears to make sure all are there.

It is so old that it was sold with the ceiling mount line-shaft transmission, rather than with an electric motor. The lathe came with a very old Bendix washing machine motor, obviously not original. The line-shaft transmission is interesting, it has two large flat belt pulleys to link this into the wider shop belt system, and a left-right shifter mechanism that pushes a cone over, engages a pawl and causes a friction clutch type mechanism to expand inside of the pulley, which when engaged causes the inner shaft to rotate and therefore turn the three step pulley and engage the lathe.

I am not planning on reusing the motor supplied, will likely either find a 3 phase motor and add VFD or find a treadmill/DC motor and controller. I work with VFDs a lot for work and am comfortable on the electronics side of either solution. However I will need to figure out a pulley and belt solution to get the right speed ranges.

There is definitely some damage on the lathe from prior mishaps. The chuck has clearly been dropped a few times, although only the inner parts of the lathe bed seem damaged, not the outer ways. This Junior lathe has a wider bed than the newer "Workshop" lathes I believe, being derived from the earlier 10" lathe.

The compound has also clearly been crashed into the chuck a number of times. One tooth is missing on the back gear. I hope that with just one tooth out, it will still run smooth enough. The main large hand wheel on the apron is a bit wobbly, but otherwise the controls seem tight enough with what appears to be reasonable back lash.

I don't see any evidence of a ridge on the ways, and only minor knicks on the actual ways themselves.

Otherwise the lathe came with a few bits of tooling.

At some point someone cut a drum in half and welded some angle iron together to make a removable chip pan.

I definitely am not a lathe expert, having only run one a few times.

Today I degreased and cleaned up the cast iron legs and got a coat of Rustoleum primer on them. It appears the lathe has been repainted standard Rustoleum Smoke Gray so I will be doing the same on the legs and chip pan to match.

So my overall to-do:

1. Get legs painted

2. Figure out leveling feet solution

3. Remount lathe to legs and get level

4. Figure out motor/drive belt and pulleys

5. Get appropriate oils and grease

6. Test the lathe! Was not able to run under power so next I will need to evaluate what I actually have.

If all seems well once under power I will then start trying to do more with it. I would like to get a drill chuck for the tail stock, need to learn to grind some tooling and just start learning the lathe.

It wasn't quite what I was looking for (was trying for a Model A with QC box) but the price was quite right, being approximately the cost of a used HF 7x10 lathe.

Thanks for looking!

Bill