- Joined

- Jan 20, 2021

- Messages

- 296

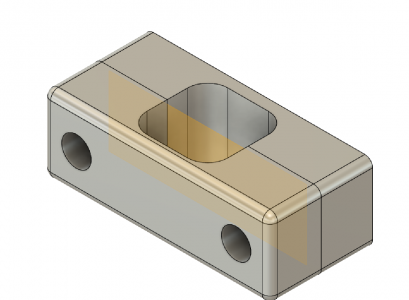

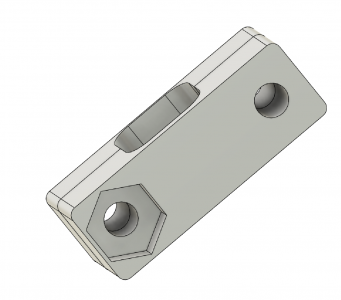

One of my design intents is to use existing fastener locations, threaded holes, etc whenever possible. This is true whether its a car, machine tool, or whatever. The Haas in my first venture into true automation. I want things tidy, up and out of the way. Drew a clamp for the Fogbuster hoses.

This first clamp is for #10 screw locations on the side of the head. Captured nut for the free end of the clamp.

This first clamp is for #10 screw locations on the side of the head. Captured nut for the free end of the clamp.