- Joined

- Nov 5, 2018

- Messages

- 100

This one had some thick rubber under the part where the lathe attaches to the base. The cabinet is sitting on a finished concrete floor and I checked the bed for level and it looks good. Would you still recommend making the leveling feet?Looks good! That cabinet looks to be in good shape.

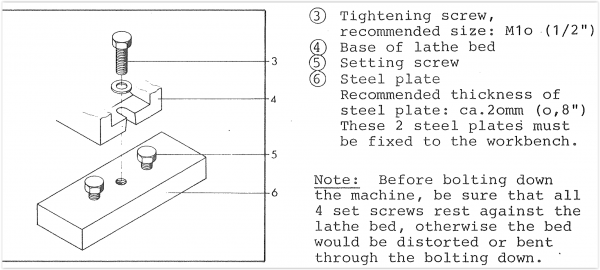

The Compact 8 was intended to be bolted flat to the cabinet and the lathe was leveled by shimming/leveling the cabinet itself. Needless to say, this is tedious. On my friend's lathe, we installed leveling bolts under the feet to greatly ease leveling adjustments and I would highly recommend you consider doing the same.

This is what sits under my Super 11CD and also under my friend's Compact 8:

View attachment 279617

You would need to do a little drilling and tapping but it is well worth doing, and now is the time.

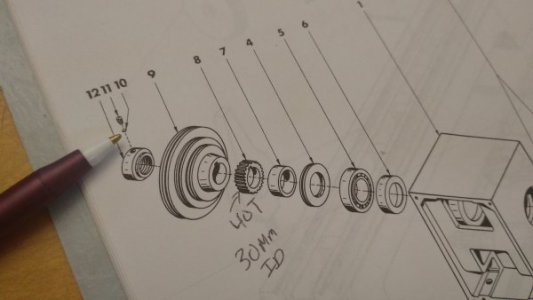

I looked at mine and I see it has been painted. I guess you are right, a small piece of brass to prevent the thread from galling. I soppose you would need to preload the spindle bearings.I ddont know if you have a manual or if its mentioned in the manual but I guess you tighten the nut untill you get no axial and radial play and run it at the fastest speed for fifteen minutes. If it gets warm but not hot you are good to go. I dont want to break the paint seal under mine but I am sure its just a protective insert.I have started reassembling the headstock and noticed a missing part on the spindle nut. I have attached a picture of the missing part I found in the parts manual. It is part #10 on the illustration and labled as "Disk". I'm assuming the disk is made of aluminum, plastic or brass to protect the threads on the spindle from the steel set screw. Is that correct? If so I can make a new one without any problems, but I'm just wanting to make sure I'm understanding what it looks like I'm seeing correctly.

Thanks for any thoughts about this part!View attachment 279698