- Joined

- May 8, 2018

- Messages

- 336

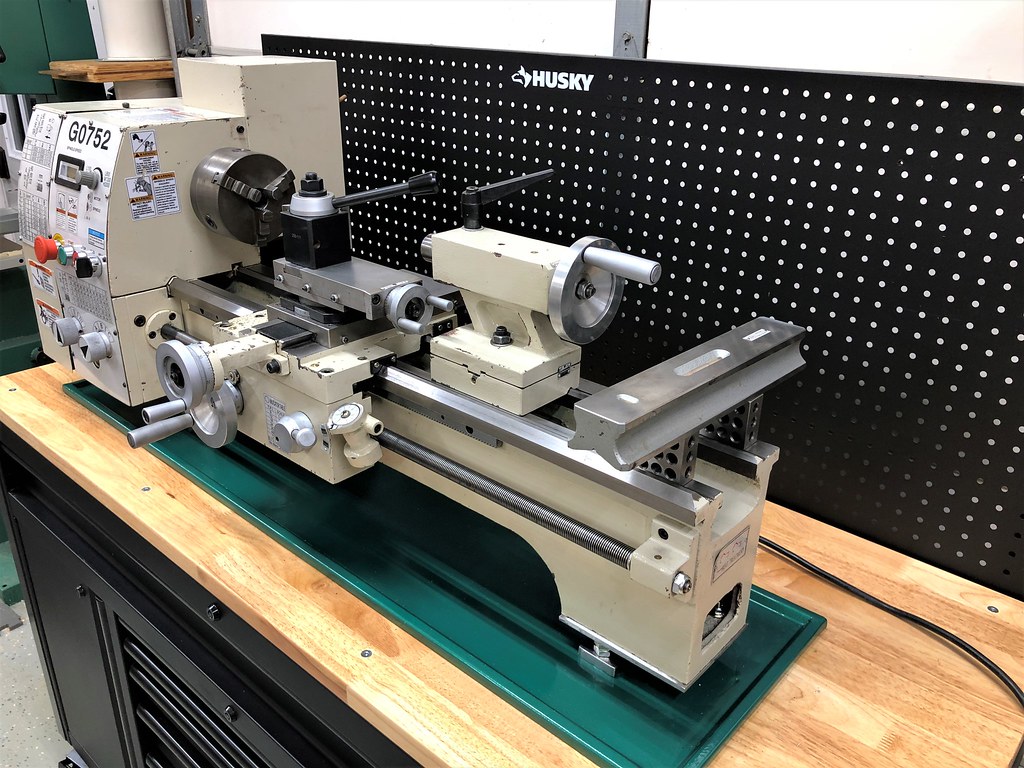

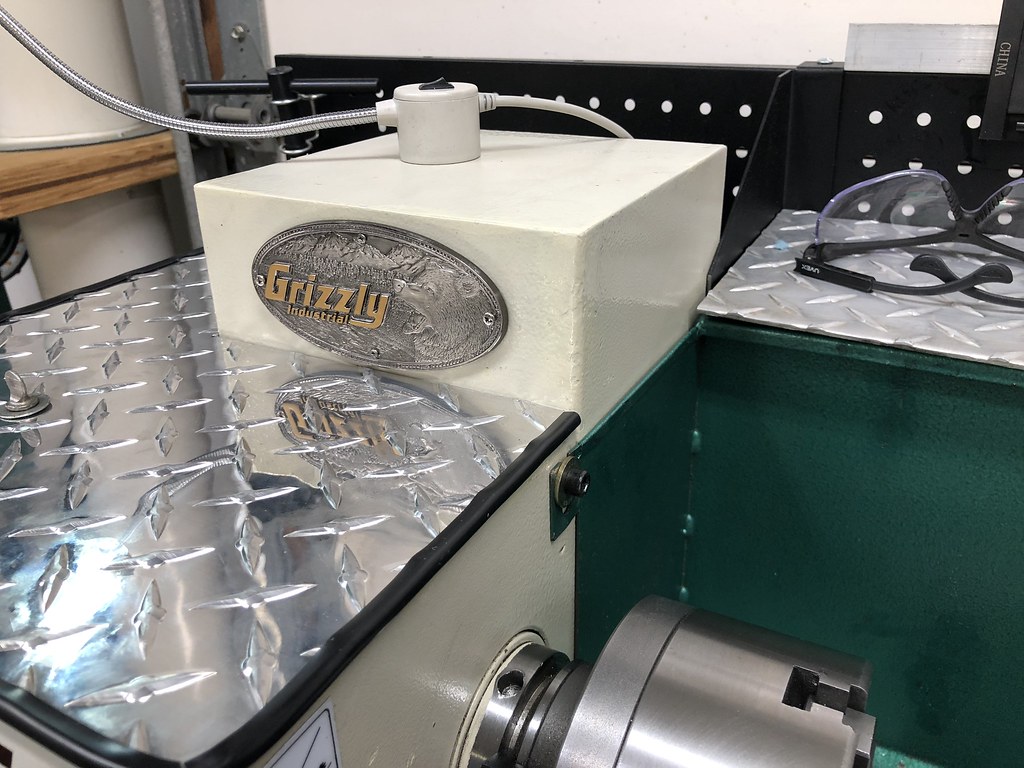

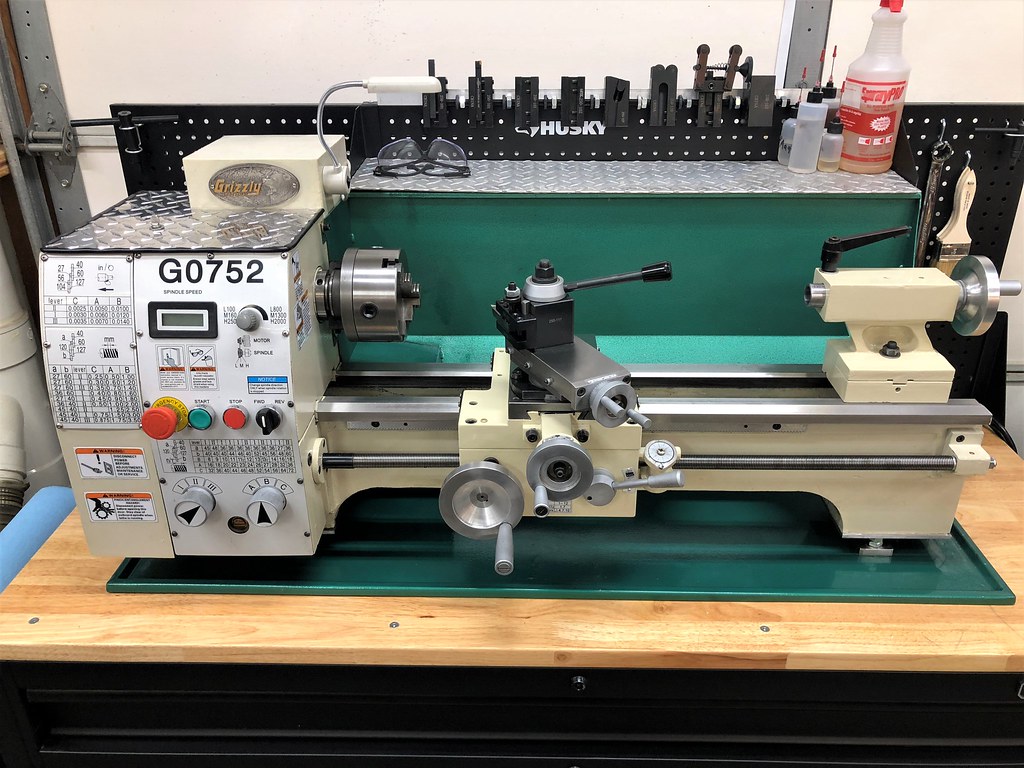

I love my G8688 mini but after living with it for a while I really wanted a bigger lathe. Decided that going up to one of the 10x22ish lathes would be a logical next step. There is a gentleman in my area (1.5 hours away) that buys machines at the Grizzly tent sales and refurbs and resells them. This was actually his personal lathe. He replaced it with a Shop Fox gunsmith lathe. I got the lathe and all the accessories it originally came with for $1200.

Couple of crank straps secured it for the ride home...

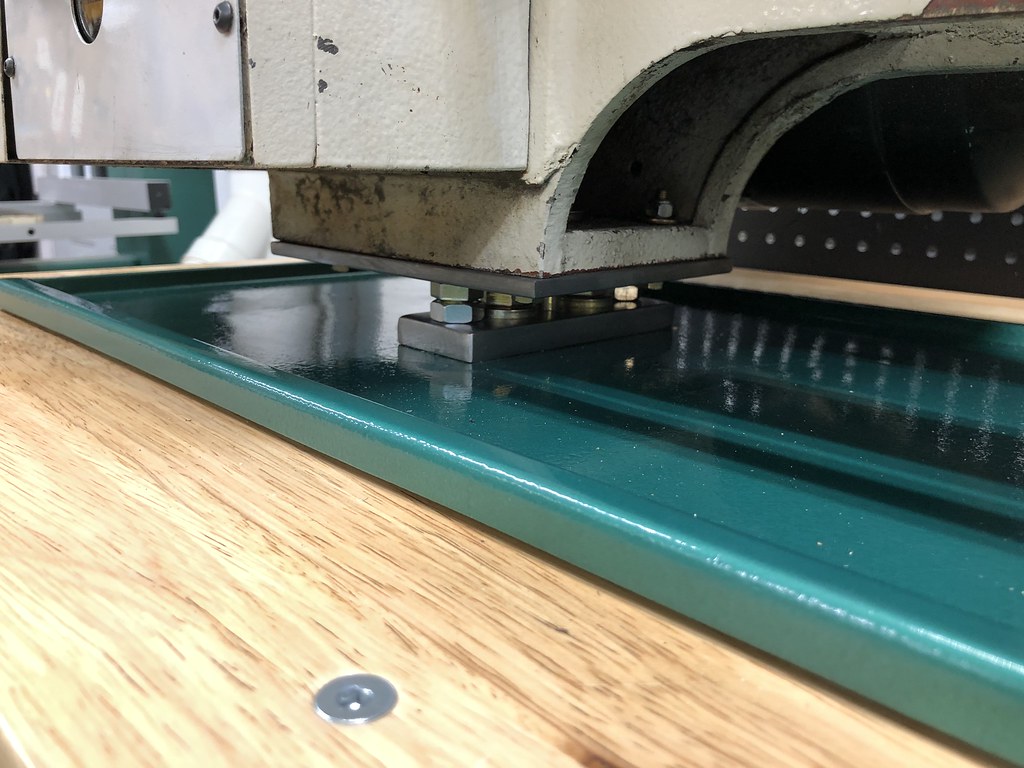

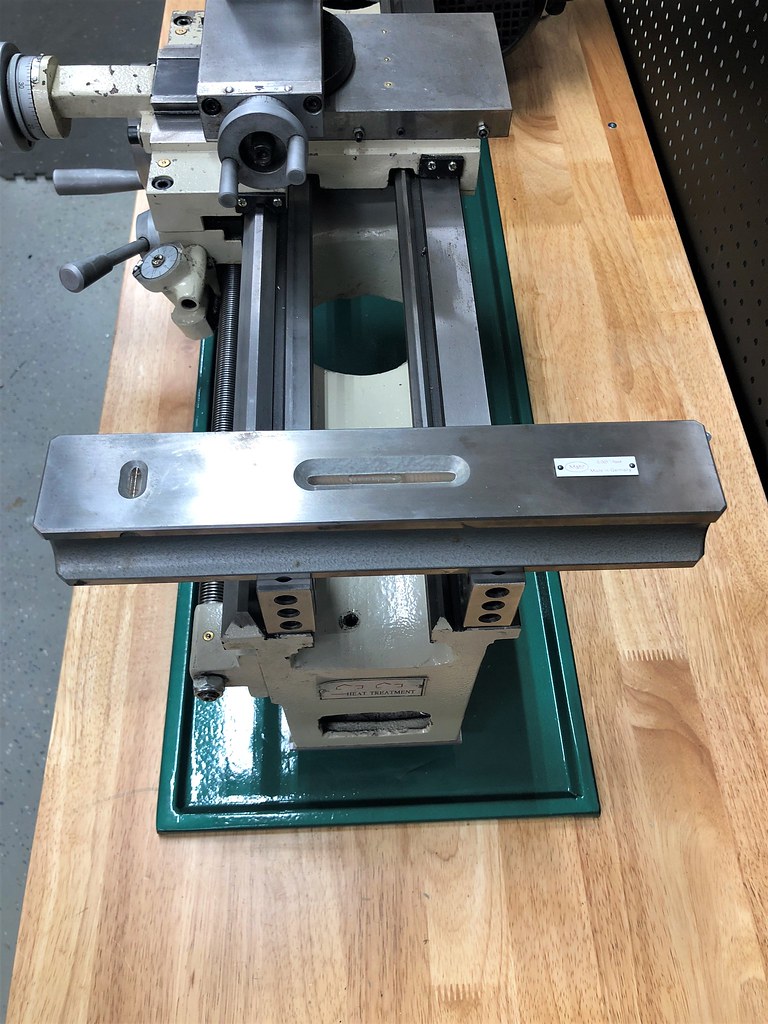

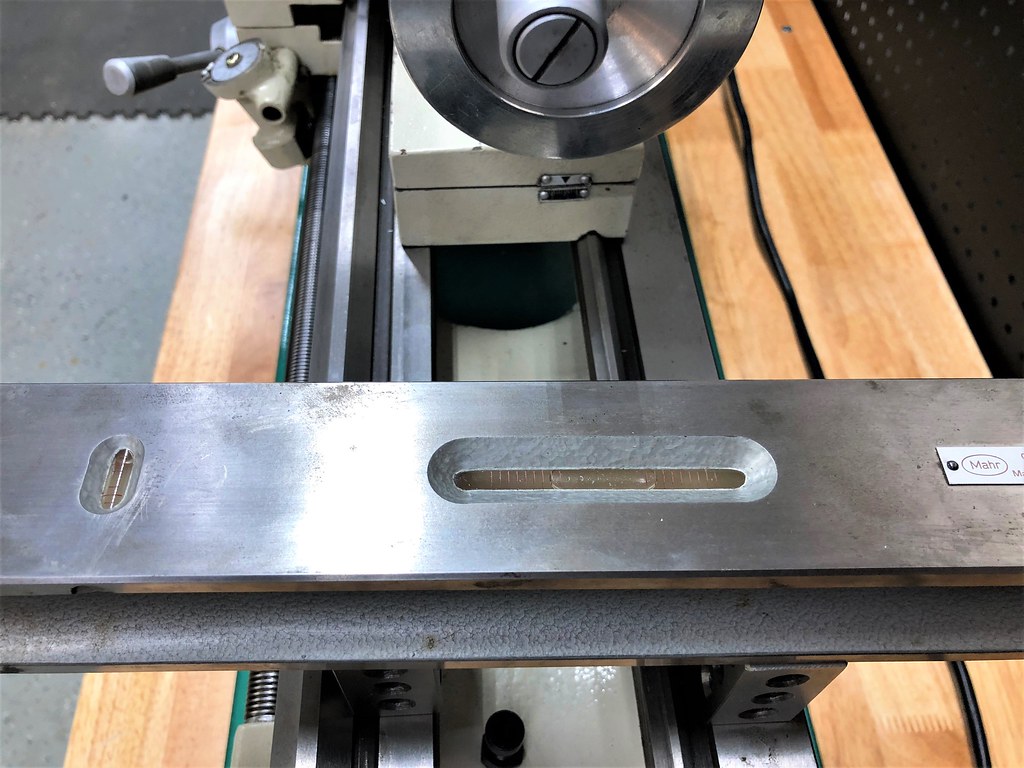

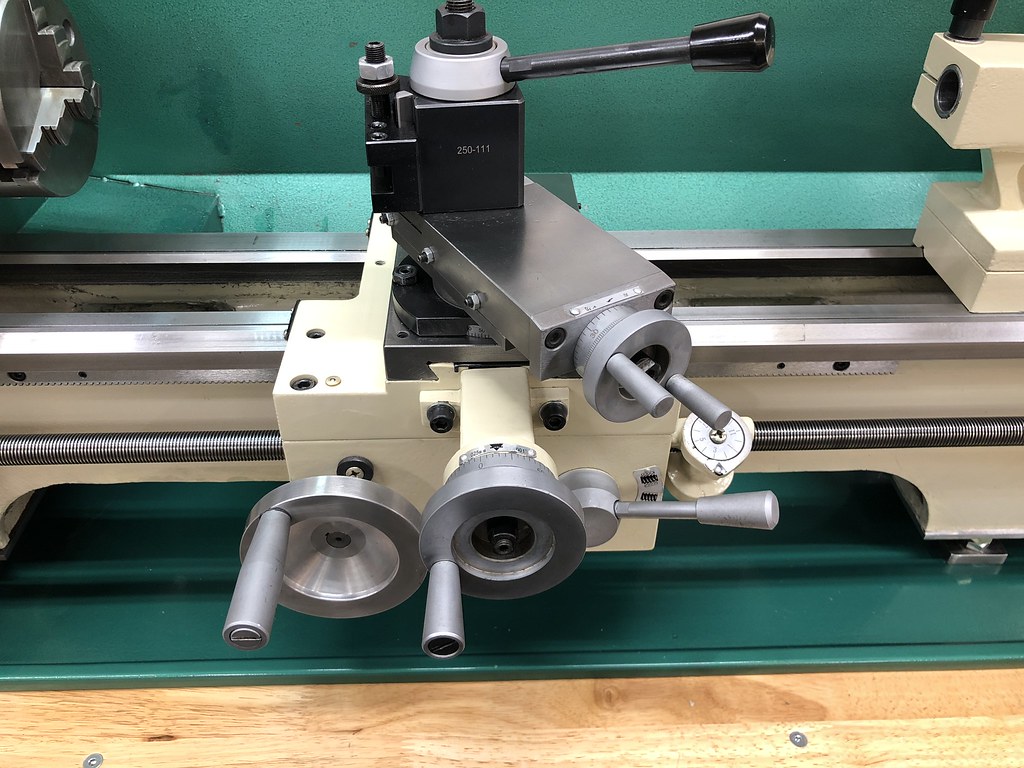

I bought a Husky 61" rolling workbench while they were on sale a couple of weeks ago for it's new home. I have quite a few things I'd planning on doing to it. First will be repainting the chip tray but couldn't resist sitting it on the bench just to see how it looked last night.

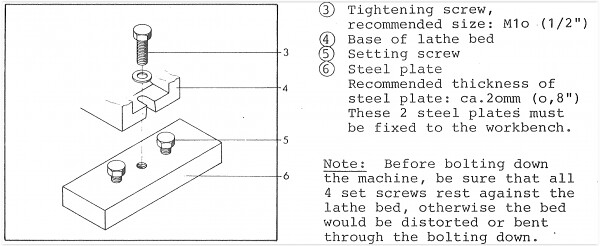

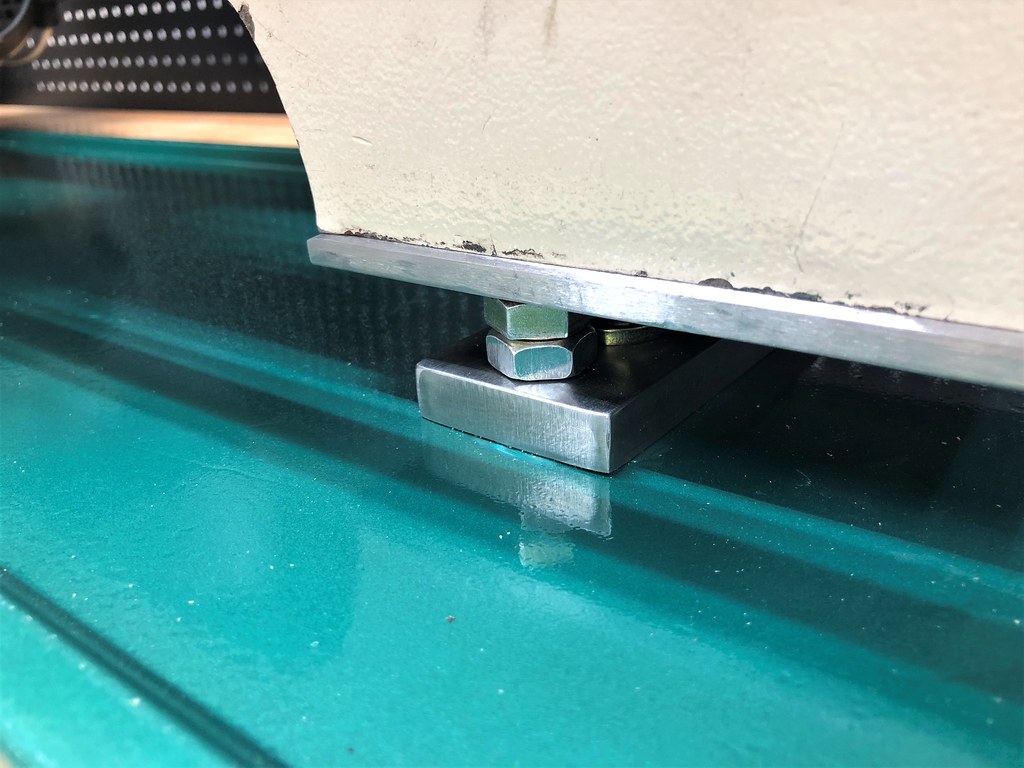

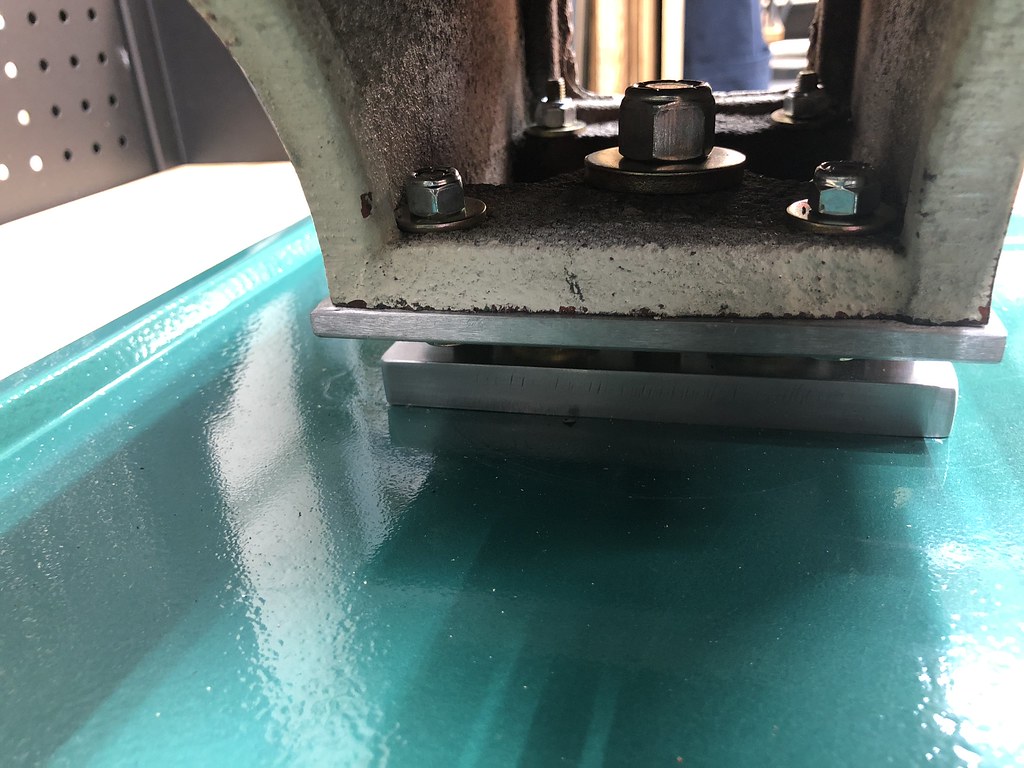

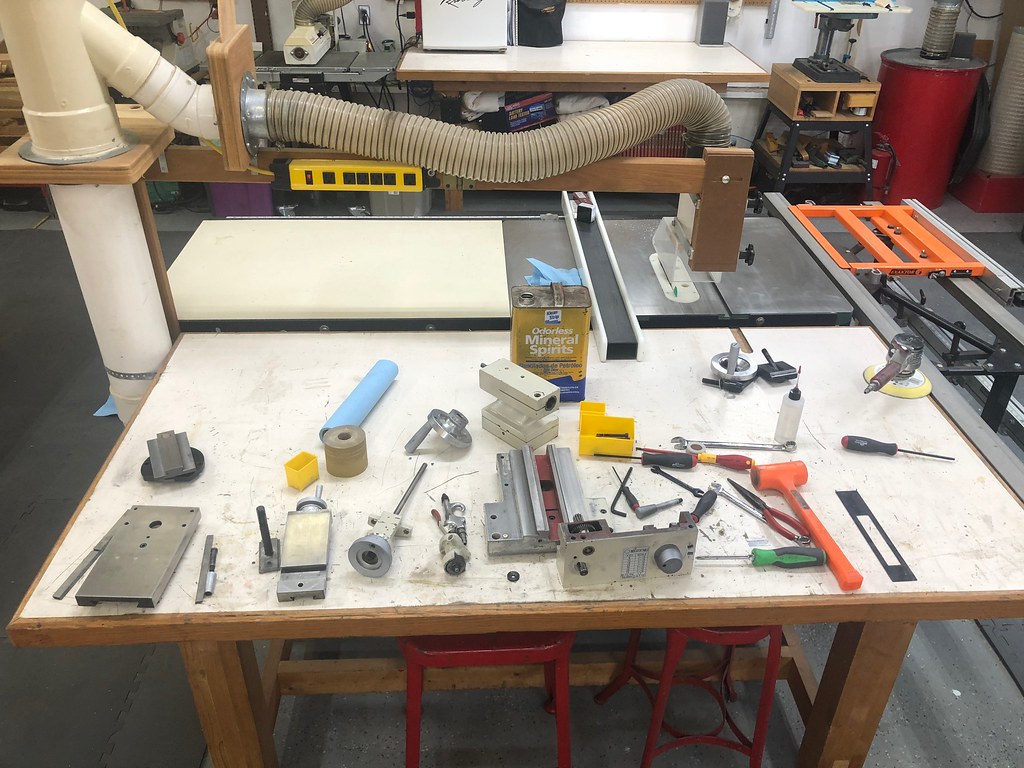

Next up is to repaint the chip tray and begin the mounting process. I'll be adding a wedge QCTP and doing a few other mods. More to come...

Couple of crank straps secured it for the ride home...

I bought a Husky 61" rolling workbench while they were on sale a couple of weeks ago for it's new home. I have quite a few things I'd planning on doing to it. First will be repainting the chip tray but couldn't resist sitting it on the bench just to see how it looked last night.

Next up is to repaint the chip tray and begin the mounting process. I'll be adding a wedge QCTP and doing a few other mods. More to come...