- Joined

- Mar 12, 2021

- Messages

- 63

So about a month or so ago while hunting FB marketplace, craiglist etc. for a decent used benchtop or smaller lathe I stumbled on this guy. Initially listed at 500 bucks I was chomping at the bit/afraid something was critically wrong with it. turns out inexperienced seller and after some chatting and other peoples offers I ended up taking it home for just north of 1k (i hope/dont think that was tooo bad of a deal) here around WI its pretty dry for used machinery and I still drove 4 hrs each way to get it.

Edit its the 12x 24 should be enough to suit my needs and still plenty heavy/beefy

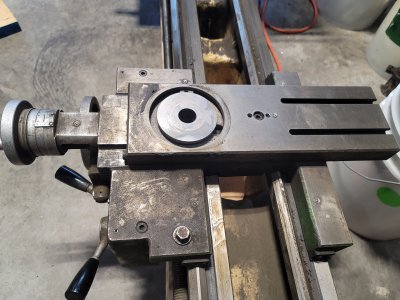

EDIT: above is before pic at pickup and below is after teardown cleaning and relubrication.

In situe in a walk out basement sure was interesting to move and absolutely filthy, but i was able to observe under power shift the gearbox and engage all the feeds and directions so it seemed all good for a novice, and the ways looked in good shape if not hella dirty which seemed to protect it at least.

Came with what I think are all the original accessories

the c shaped steady rest

circular 3 point steady rest

3 jaw chuck,

4 jaw chuck,

face plate,

original 4 way tool post,

the two change gears for metric (thank goodness found in the most oil and dirt caked plastic bag in a corner of one of the drawers),

original manuals (and receipt even)

as well as a 5C collet closer a rack of 5c collets in seemingly interesting assortment not really a full set but not complaining probably picked up as needed will likely do the same to finish that out.

a drawer full of assorted tooling not sure how much of it is good or not or what some of it is.

And the stand which apparently came from IBM once upon a time which used to be a cast iron table for punch card computers?

and like 3-4 buckets of aluminum and steel stock and scrap

packed up for the long ride home (think 3 stops along the way to recheck and readjust strapping and blocking) brought a engine hoist along and boy was I glad we did, took 2-3 hrs to remove machine and get it on the trailer and about 4 buckets of stuff out of the cabinet/stand which is cast iron by the way and weighs quite alot in itself

here she is home and awaiting disassembly and cleaning. also pro tip cover the sight gauges or the venturi effect will just suck all the oil out thru the air event holes!

I will admit there are some minor regrets after the drive to get it and back and the following cleanup and teardown which ill cover more in future post replies as man its been quite a lot of cleaning. I will also sprinkle in bits and pieces of "what is it" trying to figure out what something might be or if it may be something the previous owner included that may not even make sense in association with

I have my gallon of WD40, WD40 Degreaser, and mineral spirits and a ton of paper towels, and still quite a task ahead of me (even though at the time of writing this I'm a good ways into it)

Edit its the 12x 24 should be enough to suit my needs and still plenty heavy/beefy

EDIT: above is before pic at pickup and below is after teardown cleaning and relubrication.

In situe in a walk out basement sure was interesting to move and absolutely filthy, but i was able to observe under power shift the gearbox and engage all the feeds and directions so it seemed all good for a novice, and the ways looked in good shape if not hella dirty which seemed to protect it at least.

Came with what I think are all the original accessories

the c shaped steady rest

circular 3 point steady rest

3 jaw chuck,

4 jaw chuck,

face plate,

original 4 way tool post,

the two change gears for metric (thank goodness found in the most oil and dirt caked plastic bag in a corner of one of the drawers),

original manuals (and receipt even)

as well as a 5C collet closer a rack of 5c collets in seemingly interesting assortment not really a full set but not complaining probably picked up as needed will likely do the same to finish that out.

a drawer full of assorted tooling not sure how much of it is good or not or what some of it is.

And the stand which apparently came from IBM once upon a time which used to be a cast iron table for punch card computers?

and like 3-4 buckets of aluminum and steel stock and scrap

packed up for the long ride home (think 3 stops along the way to recheck and readjust strapping and blocking) brought a engine hoist along and boy was I glad we did, took 2-3 hrs to remove machine and get it on the trailer and about 4 buckets of stuff out of the cabinet/stand which is cast iron by the way and weighs quite alot in itself

here she is home and awaiting disassembly and cleaning. also pro tip cover the sight gauges or the venturi effect will just suck all the oil out thru the air event holes!

I will admit there are some minor regrets after the drive to get it and back and the following cleanup and teardown which ill cover more in future post replies as man its been quite a lot of cleaning. I will also sprinkle in bits and pieces of "what is it" trying to figure out what something might be or if it may be something the previous owner included that may not even make sense in association with

I have my gallon of WD40, WD40 Degreaser, and mineral spirits and a ton of paper towels, and still quite a task ahead of me (even though at the time of writing this I'm a good ways into it)

Last edited: