I have been chasing this lathe for over 12 months and recently the deal finally got concluded and this lathe now resides (temporarily) at work.

It is a Peerless PL 36-910 which is a 1970's vintage with the small 27mm spindle hole, and by the looks of it has hardly been used, but does suffer from sun fade.

There is a mark (flaking) in the bed up by the chuck, looking at it it looks like the bed is chromed and some of the chrome has flaked away, has anyone else noticed that the bedway on these Taiwanese belt drive lathes were chromed?

It also came with the steadies, faceplate, 4 jaw chuck and some hss steel tooling, oh and it is the first and only one of these I have seen with a milling attachment.

The lathe is 3 phase and the milling attachment is single phase, I am unable to run the lathe because I don't have the key for the electrical switch on top of the electrical panel so may have to bypass that to get the lathe to run.

Before I try running it i may need to do a bit of lubing to make sure everything still turns, I found the threading indicator was seized with dried lube.

I bought this lathe for a specific reason, and when I was looking at all the info I could find on the Taiwanese belt drive lathes I found that there were a few changes over the years, from a 27mm spindle hole to a 38mm spindle hole, and from a 2MT tailstock to a 3 MT, there were other differences like increased swing. Lathes.co.uk has quite a good write up about the various changes that happened during the evolution of this lathe.

One of my specific reasons for purchase was that it is belt drive, so quieter than a gearhead lathe. My workshop is actually a basement garage and noise travels up, so I wanted a lathe with reduced noise. I have seen most of these Taiwanese belt drive lathes have a threaded spindle nose, but have seen one or two which have a D1-4 spindle nose, these do not seem very common. My manual doesn't give the bearing size for the spindle but I am wondering if they are the same size that the 38mm spindle hole spindle uses.

Does anyone know the bearing sizes of the small spindle hole spindle?

I will be converting this to vfd as I do like the benefits of 3phase motors, but that is for the future,

The chromed bedways with a bit flaked off.

Mascotools milling attachment, it is single phase and only has 4 speeds

Doesn't look like it has had much use, but looks like it was lubed.

The tailstock is 2MT and the paint is flaking off

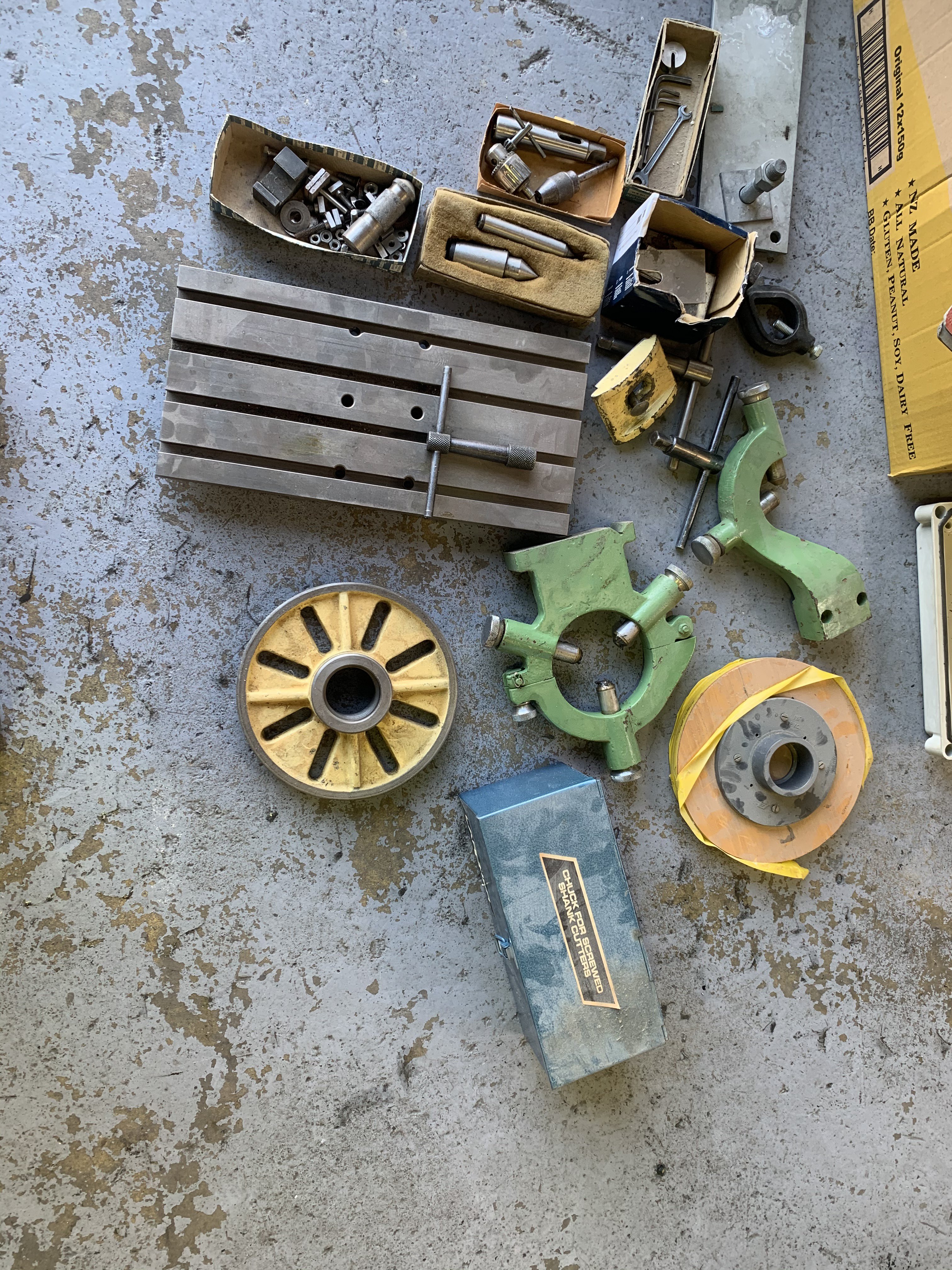

The milling table that attaches to the cross slide, steadies, milling chuck, centres etc

A live centre and the other set of jaws for the 3 jaw chuck

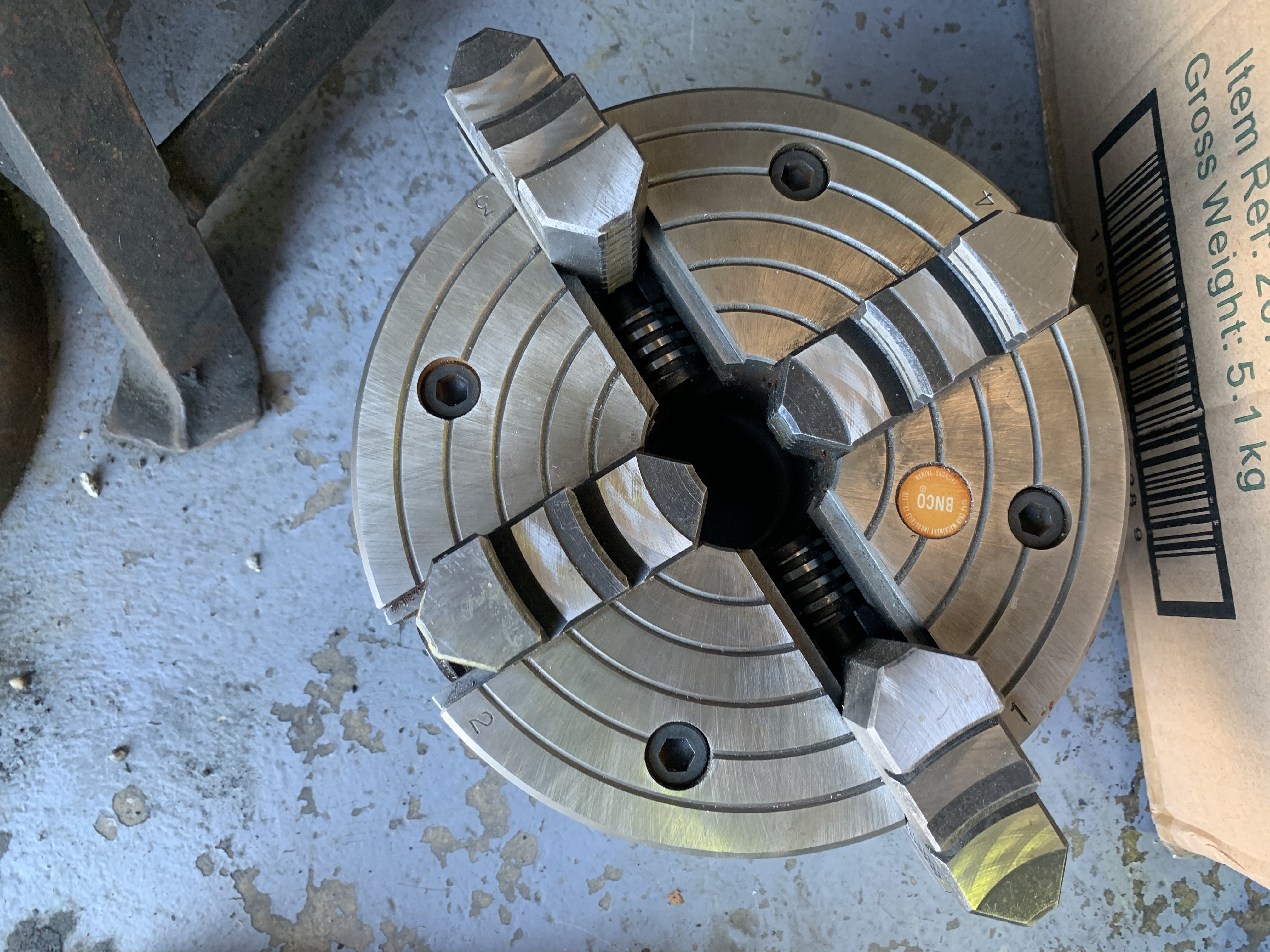

The 200mm four jaw chuck

And the original tool kit

I also got a folder with the original manual for the lathe and the original invoices for the lathe, drill chuck and some other tooling. There was no manual for the milling attachment.

The threading and feed charts on the front of the lathe are that sun faded they are illegible, but I may be able to get these out of the manual.

It is a Peerless PL 36-910 which is a 1970's vintage with the small 27mm spindle hole, and by the looks of it has hardly been used, but does suffer from sun fade.

There is a mark (flaking) in the bed up by the chuck, looking at it it looks like the bed is chromed and some of the chrome has flaked away, has anyone else noticed that the bedway on these Taiwanese belt drive lathes were chromed?

It also came with the steadies, faceplate, 4 jaw chuck and some hss steel tooling, oh and it is the first and only one of these I have seen with a milling attachment.

The lathe is 3 phase and the milling attachment is single phase, I am unable to run the lathe because I don't have the key for the electrical switch on top of the electrical panel so may have to bypass that to get the lathe to run.

Before I try running it i may need to do a bit of lubing to make sure everything still turns, I found the threading indicator was seized with dried lube.

I bought this lathe for a specific reason, and when I was looking at all the info I could find on the Taiwanese belt drive lathes I found that there were a few changes over the years, from a 27mm spindle hole to a 38mm spindle hole, and from a 2MT tailstock to a 3 MT, there were other differences like increased swing. Lathes.co.uk has quite a good write up about the various changes that happened during the evolution of this lathe.

One of my specific reasons for purchase was that it is belt drive, so quieter than a gearhead lathe. My workshop is actually a basement garage and noise travels up, so I wanted a lathe with reduced noise. I have seen most of these Taiwanese belt drive lathes have a threaded spindle nose, but have seen one or two which have a D1-4 spindle nose, these do not seem very common. My manual doesn't give the bearing size for the spindle but I am wondering if they are the same size that the 38mm spindle hole spindle uses.

Does anyone know the bearing sizes of the small spindle hole spindle?

I will be converting this to vfd as I do like the benefits of 3phase motors, but that is for the future,

The chromed bedways with a bit flaked off.

Mascotools milling attachment, it is single phase and only has 4 speeds

Doesn't look like it has had much use, but looks like it was lubed.

The tailstock is 2MT and the paint is flaking off

The milling table that attaches to the cross slide, steadies, milling chuck, centres etc

A live centre and the other set of jaws for the 3 jaw chuck

The 200mm four jaw chuck

And the original tool kit

I also got a folder with the original manual for the lathe and the original invoices for the lathe, drill chuck and some other tooling. There was no manual for the milling attachment.

The threading and feed charts on the front of the lathe are that sun faded they are illegible, but I may be able to get these out of the manual.

Last edited: