- Joined

- Jul 7, 2020

- Messages

- 71

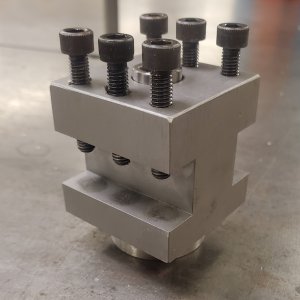

I have been meaning to make a new tool post for my Craftsman 618 lathe for awhile now. The tiny lantern is hard to adjust and I feel the quick change tool post I have is just a step away from a broken cross slide and not ridgid enough, and ridgidity is not something you can spare with these tiny 6" lathes.

Basic design machined out of a block of 1018 I had lying around and s definite improvement over the other tool posts that I have.

Basic design machined out of a block of 1018 I had lying around and s definite improvement over the other tool posts that I have.