- Joined

- Jul 14, 2017

- Messages

- 2,446

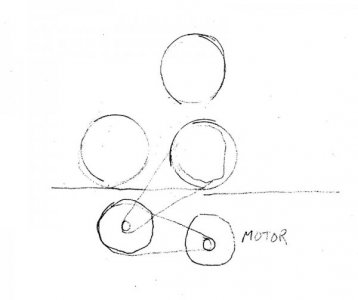

I've dabbled in a lot of things but have never owned a bandsaw, i've used some before but they were already set up and ready to use, earlier today i bought this one at a tool market looks like a good quality machine until i looked inside and found that is toothed belt driven and has plastic wheels, anyway i have no experience in setting up speeds and saw blades, i would like to cut thin metal, any advice and experience is welcome.