- Joined

- Dec 27, 2017

- Messages

- 340

Hi everyone,

I thought I would make my first post about a recent success I had with a makeshift spray mist system that I cobbled together. To start, I used to use flood coolant (water mostly) to cool aluminum when I wanted to run a higher feed rate on my mill. All was well with the idea except that I found my flood coolant system required more maintenance than what I was expecting. Also, my shop is not insulated, so the winters present freezing issues. For a short time I used WD-40 as my coolant, but quickly found out that it could produce a lot of smoke once the feed rates went up.

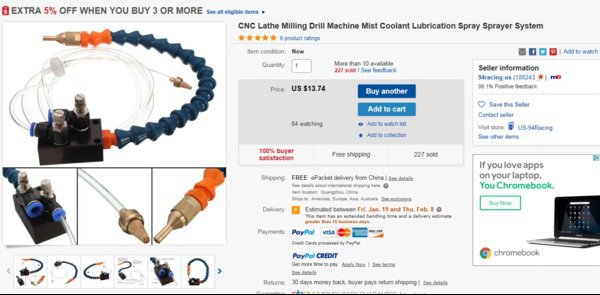

After this, I thought about spray mist coolant and wondered if a system like that could provide enough cooling for my aluminum and also create less mess. I looked at my options and decided that I would go with those import spray mist lines. I purchased two of them from eBay and they shipped from the Chinese motherland. About two weeks later they came in the mail and I was eager to put them to use and see if they would do the job.

My setup consisted of a 1/3hp scientific vacuum pump, air lines and the all important water lines from a Tupperware style container that made their way to the spray mist lines. Now, these lines were the kind that did not have two adjustable needles (one for the air and one for the water) but rather only one ball valve the air in. I also found those mist lines needed more air than what my vacuum pump could deliver and trying to adjust air pressure to meter the water flow was close to impossible. After a couple of days of tinkering with the setup, I decided that it was just not reliable enough to put my end mills on the line and hope that they would receive the cooling that they required.

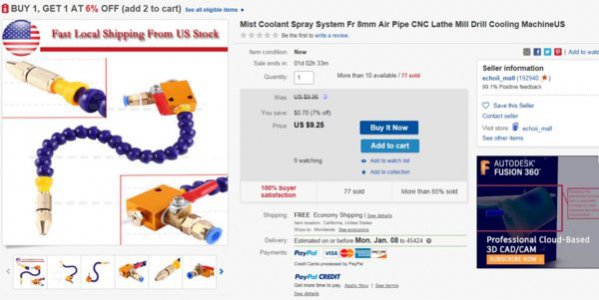

I went back on eBay and looked at some more options and came across a different kind of spray mist line. This one seemed to have two needle valves on it and I suspected that perhaps this type would work for my application. I went ahead and ordered those two from the Chinese motherland and they came in a couple of weeks. Once they came in I installed them on the mill and set everything up as I had done previously. I turned on my vacuum pump and I immediately saw that the gauge jumped to over 25psi and started to load up the motor. I adjusted the pressure bleed valve and toned down the pressure to about 15psi. I checked the mist nozzles and they were both blowing a nice amount of air along with a fair amount of water being drawn out. At this point, I worked the water adjustment needles and I was able to get them to where one could just barely make out a faint trace of water leaving the nozzles.

Needless to say I was very pleased with the result. Not long after I went ahead and loaded up a 3/8" end mill, popped a hunk of aluminum in the vice and fired up the spindle for a test. I took a 0.150" width of cut with a 0.300" depth of cut at 3000rpm and 24ipm. The performance of the cut showed no issues with overheating and I was free to use the full power of the mill without concern of aluminum getting soft and clogging the end mill.

I thought I would make my first post about a recent success I had with a makeshift spray mist system that I cobbled together. To start, I used to use flood coolant (water mostly) to cool aluminum when I wanted to run a higher feed rate on my mill. All was well with the idea except that I found my flood coolant system required more maintenance than what I was expecting. Also, my shop is not insulated, so the winters present freezing issues. For a short time I used WD-40 as my coolant, but quickly found out that it could produce a lot of smoke once the feed rates went up.

After this, I thought about spray mist coolant and wondered if a system like that could provide enough cooling for my aluminum and also create less mess. I looked at my options and decided that I would go with those import spray mist lines. I purchased two of them from eBay and they shipped from the Chinese motherland. About two weeks later they came in the mail and I was eager to put them to use and see if they would do the job.

My setup consisted of a 1/3hp scientific vacuum pump, air lines and the all important water lines from a Tupperware style container that made their way to the spray mist lines. Now, these lines were the kind that did not have two adjustable needles (one for the air and one for the water) but rather only one ball valve the air in. I also found those mist lines needed more air than what my vacuum pump could deliver and trying to adjust air pressure to meter the water flow was close to impossible. After a couple of days of tinkering with the setup, I decided that it was just not reliable enough to put my end mills on the line and hope that they would receive the cooling that they required.

I went back on eBay and looked at some more options and came across a different kind of spray mist line. This one seemed to have two needle valves on it and I suspected that perhaps this type would work for my application. I went ahead and ordered those two from the Chinese motherland and they came in a couple of weeks. Once they came in I installed them on the mill and set everything up as I had done previously. I turned on my vacuum pump and I immediately saw that the gauge jumped to over 25psi and started to load up the motor. I adjusted the pressure bleed valve and toned down the pressure to about 15psi. I checked the mist nozzles and they were both blowing a nice amount of air along with a fair amount of water being drawn out. At this point, I worked the water adjustment needles and I was able to get them to where one could just barely make out a faint trace of water leaving the nozzles.

Needless to say I was very pleased with the result. Not long after I went ahead and loaded up a 3/8" end mill, popped a hunk of aluminum in the vice and fired up the spindle for a test. I took a 0.150" width of cut with a 0.300" depth of cut at 3000rpm and 24ipm. The performance of the cut showed no issues with overheating and I was free to use the full power of the mill without concern of aluminum getting soft and clogging the end mill.