I have a Harbor Freight 7x10 lathe still covered in the factory preserving grease sitting on my work bench.

I threw out my back this past Tuesday so all I can do for now is just give it a good visual look over.

I haven't even touched a wrench to it yet.

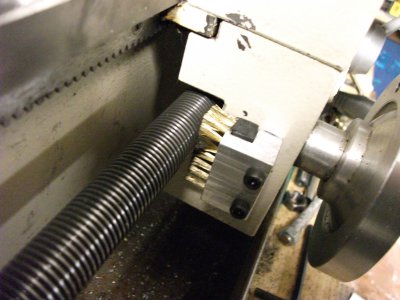

I noticed that the lead screw has a full length tin cover over it. This looks more like a PITA device when cleaning time comes around than a device for keeping swarf out of the screw threads.

I also noticed that it is soo close to the backside of the apron that there is no room for a DIY protective shield to be installed to cover the feed gears unless I make it out of Bible paper.

Is there any disadvantage if I remove it? Is there an advantage if I leave it intact? (don't say it's a swarf shield, I can already determine that for myself :rofl

Thank you in advance for any insight you might share!

I threw out my back this past Tuesday so all I can do for now is just give it a good visual look over.

I haven't even touched a wrench to it yet.

I noticed that the lead screw has a full length tin cover over it. This looks more like a PITA device when cleaning time comes around than a device for keeping swarf out of the screw threads.

I also noticed that it is soo close to the backside of the apron that there is no room for a DIY protective shield to be installed to cover the feed gears unless I make it out of Bible paper.

Is there any disadvantage if I remove it? Is there an advantage if I leave it intact? (don't say it's a swarf shield, I can already determine that for myself :rofl

Thank you in advance for any insight you might share!