- Joined

- May 31, 2011

- Messages

- 22

Hi All,

After some research on the net I found a thread on another forum which details a nudge burner which I like.

http://www.alloyavenue.com/vb/showthread.php?2895-How-to-Build-a-Nudge-Burner&

With the above in mind I set out to build this in order to upgrade my furnace from a coal fired unit to a waste oil unit. Building this is explained in the link above so I'm not going to explain that again. Here are a couple of pictures I took of the different parts.

The following 2 components where made from 20mm round brass. The first one shows the air inlet. I made this so I can connect my compressor to the burner via a quick coupler fitted to the compressor hose.

The part below is where the oil line will connect to.

The next part used to be a dome nut.......until I clamped it in the lathes chuck It has a 3mm hole on the dome side.

It has a 3mm hole on the dome side.

Below are the parts making up the oil nozzle. On the right there is the oil tip which was made from 8mm round BMS. I made this by first machining one side to a diameter of 6mm, which was threaded using a die nut. I mounted this in the dividing head on the milling machine and made a 6mm hexagon before returning it to the lathe so the rest could be turned down to 2.8mm. After all of that I drilled a 1mm hole through this tip.

The part on the left was made using a 12mm bolt. It was drilled out with a 5mm drill and the one end was tapped using a 6mm tap. The spiral grooves on the threaded side of the bolt was roughly made using a dremel.

This is how it all fits together.

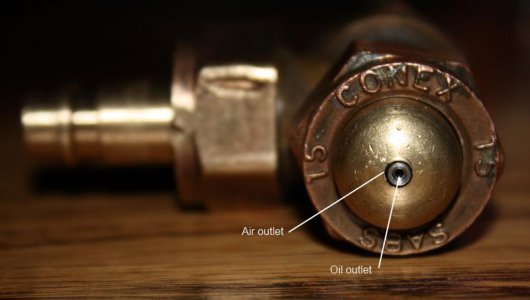

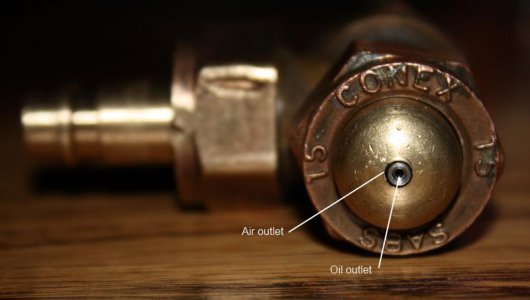

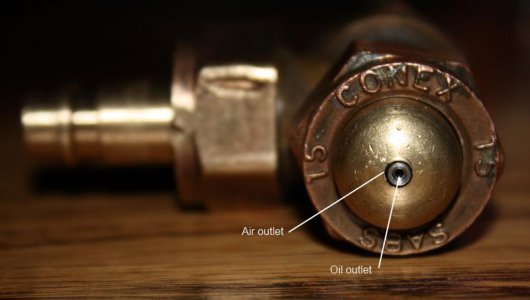

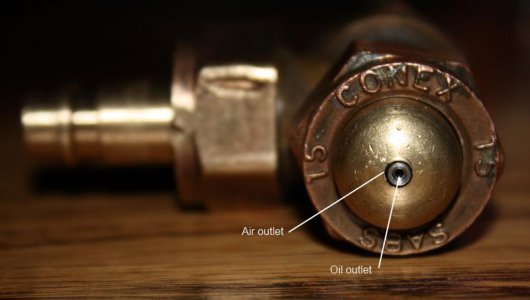

This is the view from the business end.

I tested it with water just to see it function (also not to make an oily mess) and it worked better than expected. I plan to test it with oil tonight. I'll first try it out on some aluminium, see how it melts that, then I want to try it on cast iron because I need an angle plate for my milling machine.

Till later.

After some research on the net I found a thread on another forum which details a nudge burner which I like.

http://www.alloyavenue.com/vb/showthread.php?2895-How-to-Build-a-Nudge-Burner&

With the above in mind I set out to build this in order to upgrade my furnace from a coal fired unit to a waste oil unit. Building this is explained in the link above so I'm not going to explain that again. Here are a couple of pictures I took of the different parts.

The following 2 components where made from 20mm round brass. The first one shows the air inlet. I made this so I can connect my compressor to the burner via a quick coupler fitted to the compressor hose.

The part below is where the oil line will connect to.

The next part used to be a dome nut.......until I clamped it in the lathes chuck

Below are the parts making up the oil nozzle. On the right there is the oil tip which was made from 8mm round BMS. I made this by first machining one side to a diameter of 6mm, which was threaded using a die nut. I mounted this in the dividing head on the milling machine and made a 6mm hexagon before returning it to the lathe so the rest could be turned down to 2.8mm. After all of that I drilled a 1mm hole through this tip.

The part on the left was made using a 12mm bolt. It was drilled out with a 5mm drill and the one end was tapped using a 6mm tap. The spiral grooves on the threaded side of the bolt was roughly made using a dremel.

This is how it all fits together.

This is the view from the business end.

I tested it with water just to see it function (also not to make an oily mess) and it worked better than expected. I plan to test it with oil tonight. I'll first try it out on some aluminium, see how it melts that, then I want to try it on cast iron because I need an angle plate for my milling machine.

Till later.