Here’s a solution I tried, to replace the Harig 612 Ballway Oil Pump.

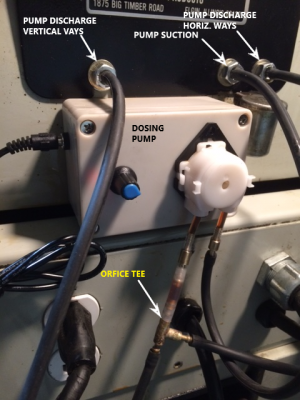

I purchased a 12V adjustable peristaltic dosing pump on Amazon. Flow rate is 8-70ml. min. The discharge size is 2mm id.

I made brass barbed fittings out of .25 brass rod. Two (2) 2mm x 0.125 reducers, One (1) 0.125 x 0.125 x 0.125 tee with the #57 drill size orifice on branch to the horizontal ways. See the Photos.

The 0.125 Bulkhead barbed fittings are made out of 5/16” bolts. I made all the fittings due to not wanting to wait for the slow boat from china as they were not available at the big box stores.

The pump was placed with the suction and discharge facing down to keep from crimping the hoses. If I was to do it again, I’d locate the pump further left to have better access to the fill cup. Same with the two bulkhead fittings.

I used the existing pump distribution discharge housing that contains the strainer on the pump inlet to the new pump. I connected a 0.125 NPT. X .0125 barbed fitting to the strainer back. The weight of the housing holds the pump inlet tube low in the oil holding sump.

So far this works pretty good… and this only cost around $35 vs $300+.

![IMG_8838[870].JPG](/data/attachments/320/320291-bb5c1d1549a4c75af5dcf20d3435e49d.jpg)