- Joined

- Jul 5, 2014

- Messages

- 2,759

It's good to know it won't take 10 days. I just gave them my facebook profile for a website.

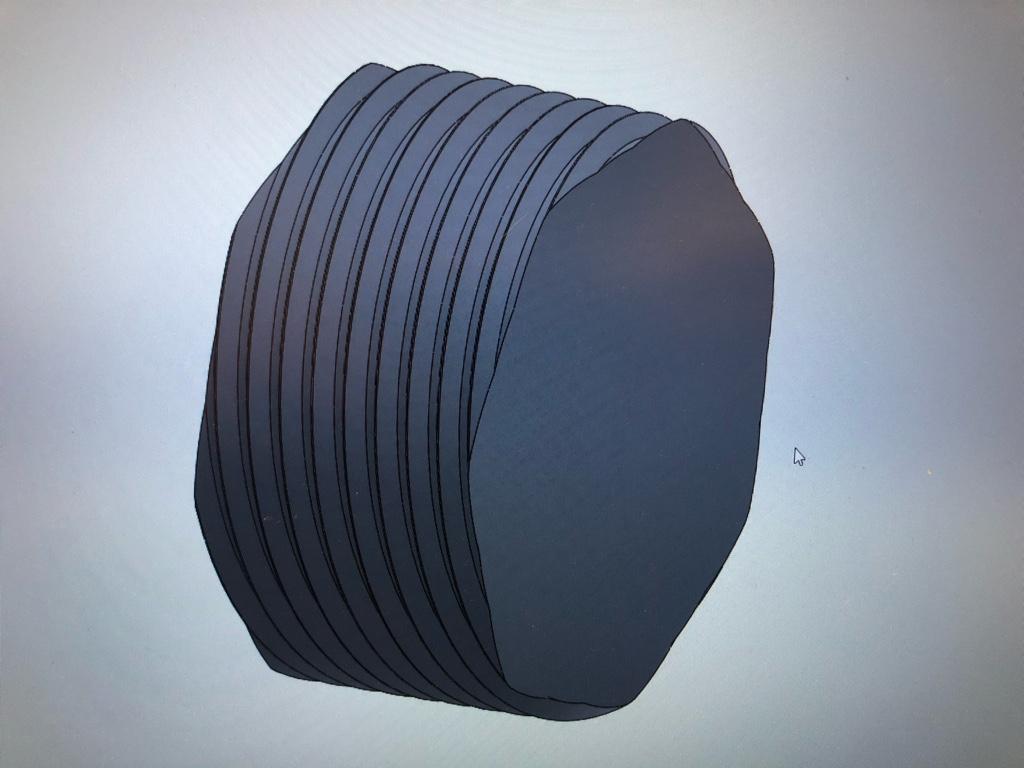

But with Jim's help we have devised a work around for the threading and it seems to be working for now. It's a pain, but it works replacing some code. The search and replace in Fusion doesn't work for this (probably on purpose) so I use the code editor in mastercam to search and replace the code I want to change. Could use wordpad also.

I've been also trying in mastercam and it just doesn't work, but I just realized while typing this I'm trying for a left hand thread, and in Fusion I'm doing a right hand thread with the tool upside down and turning the spindle clockwise. Haven't tried that in mastercam, but if it works with Fusion I won't need to.

I downloaded the program this last week so I'm guessing it's pretty up to date. When everyone wakes up I'll go out and try it again. Too early to turn my compressor on. Don't want to tick off my neighbors.

But with Jim's help we have devised a work around for the threading and it seems to be working for now. It's a pain, but it works replacing some code. The search and replace in Fusion doesn't work for this (probably on purpose) so I use the code editor in mastercam to search and replace the code I want to change. Could use wordpad also.

I've been also trying in mastercam and it just doesn't work, but I just realized while typing this I'm trying for a left hand thread, and in Fusion I'm doing a right hand thread with the tool upside down and turning the spindle clockwise. Haven't tried that in mastercam, but if it works with Fusion I won't need to.

I downloaded the program this last week so I'm guessing it's pretty up to date. When everyone wakes up I'll go out and try it again. Too early to turn my compressor on. Don't want to tick off my neighbors.