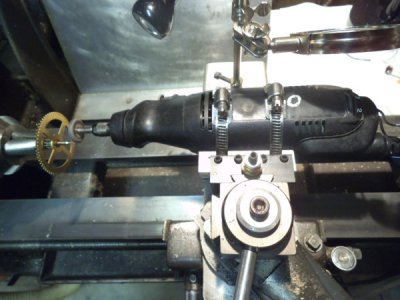

That should do fine for light work. If you want to do heavier work, use a pneumatic (or heavy duty electric) die grinder instead of the Dremel, on a heavier stand, or they can also be held in a toolholder for quicker on/off and quicker built in adjusting. I am lucky and have a Dumore tool post grinder, does the same job for a larger investment...

https://www.harborfreight.com/1-4-quarter-inch-45-cfm-air-die-grinder-92144.html the basic grinder

https://www.harborfreight.com/1-4-quarter-inch-inline-die-grinder-kit-53177.html the "professional" kit

Make sure you understand keeping the grit out of your lathe and other machines!

Just last week I ground a Grizzly 5C to 5MT collet spindle nose adapter. It was .0006" out as received from Grizzly, clocked it to .0005", ground it to .0002" runout. Next is the MT5 to MT3 sleeve that came with the lathe. It has .002" runout as it is now. The lathe spindle has .0001" runout. The lathe is still set up for tool post grinding...