- Joined

- Aug 11, 2013

- Messages

- 10

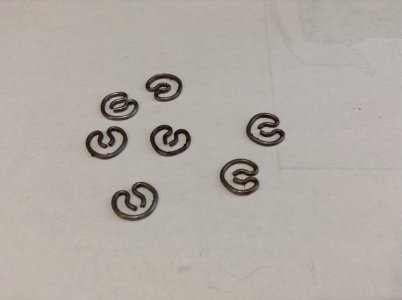

Picked this up the other day from a spring company in Chicago. Unfortunately I haven't been able to find any tags or a manufactures name on it. It's on a really nice shop made base, with a 1/2 hp variable speed drive. Looks like she's been around for a long time, making small spring clips.

I was wondering if anybody is familiar with four-slides and might have an idea on who built it. Also, any leads to some good books on tool and cam design for them.

Thanks

I was wondering if anybody is familiar with four-slides and might have an idea on who built it. Also, any leads to some good books on tool and cam design for them.

Thanks