Thank you, that's better - nice pictures. I like that your "new" machine isn't crazy long. Sure, it is a big machine, but if you aren't doing pump shafts, prop shafts, long hyd. cylinder work - then this will really fit the bill with out taking up a lot of shop space.

The spindle hole is going to be a bit small - compared to 21" lathes you would buy today. That is not a big deal, first of all you can use the bed length with the steady rest to work longer larger diameter work and secondly, there are always going to be projects too large for whatever lathe you have (go with what you have and be thankful).

I'm sure you are already looking around for tooling. You may be able to find used tooling fairly reasonably priced, since the home hobby folks are not looking for that (they usually don't look for anything over 1". Speaking for myself).

You'll be able to run carbide just fine on that machine. Carbide still works at low speed, you just don't get some of the benefits it offers. I'm learning to use some new carbide inserts - you can go with crazy high surface speeds and if the set up is solid, a good sized cut and fast feed - without coolant. Really pile up the chips.

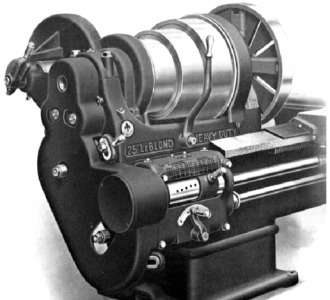

As far as the drive, I have a similar set up on my small lathe - except it was factory build and is located down in the headstock leg:

- head stock is direct / back gear

- intermediate gear box is hi/lo with internal clutches so I can shift on the fly (great for threading to a shoulder)

- 3 speed motor - each speed having its' own contactor and interlock (again, switch on the fly)

This little lathe is over 50 years old but this speed change arrangement works great. With VFD's now, you could set that up to be a sweet machine.

I don't know if your upper gear box is a factory offering (I suspect not), but it may still work well as part of the future drive arrangement (the belts etc. look a bit scary - you'll fix that).

I know that is a big lump of metal (some would say ugly lump of metal - but not here in this audience) and the chains will not hurt it. Still, see if you can do your rigging and tie down with web or straps. Wouldn't want to scratch the paint!

Show us pictures when you get it in the shop.