- Joined

- Oct 14, 2014

- Messages

- 1,967

My son recently bought a used Omax 55100 waterjet at auction.

I had another thread about getting him a 240 to 480 transformer but thought I'd better start a thread with a better description. https://www.hobby-machinist.com/threads/settle-a-bet-on-transformer.99660/

Went to my son's place to check out the transformer. we got it running a 440 volt 3 phase motor, all looks great here. He's all set to permanently wire it in to the waterjet.

Spent most of the time looking over the machine and especially the control.

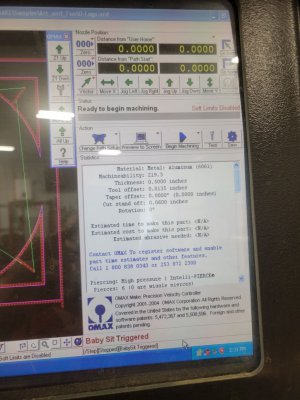

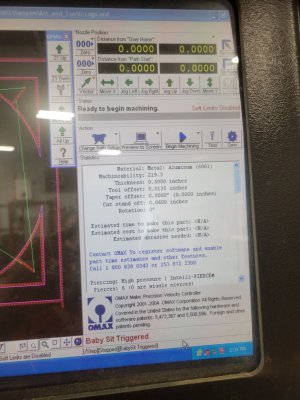

The control is a PC based stepper controller. it has a proprietary USB control box. This device then feeds proprietary driver cards that converts steps to DC servo drive. The servos are tiny by CNC standards. the control just has a few outputs from the USB control box. Looks like this box also has just a few inputs - servo fault being the most important one. the whole thing looks a lot like a Mach 3 stepper control.

Did a bit of power wire tracing. It looks like the PC, servos, etc. all take 120 VAC power from a 480 to 120 transformer. It sure looks to me like the kid can buy a PC, install the software. then remove these two wires and connect to a wall outlet. I think he will be able to jog the machine around at this point. Does anyone know for sure???

OK, his job for the week is install all power wiring, get a PC and install software.

My job is read all the manuals and try to learn all I can about starting up a water jet.

By chance, if anyone out there is expert on this machine, I'd sure like to hear from you. Neither of us have done more than just watch one run.

I had another thread about getting him a 240 to 480 transformer but thought I'd better start a thread with a better description. https://www.hobby-machinist.com/threads/settle-a-bet-on-transformer.99660/

Went to my son's place to check out the transformer. we got it running a 440 volt 3 phase motor, all looks great here. He's all set to permanently wire it in to the waterjet.

Spent most of the time looking over the machine and especially the control.

The control is a PC based stepper controller. it has a proprietary USB control box. This device then feeds proprietary driver cards that converts steps to DC servo drive. The servos are tiny by CNC standards. the control just has a few outputs from the USB control box. Looks like this box also has just a few inputs - servo fault being the most important one. the whole thing looks a lot like a Mach 3 stepper control.

Did a bit of power wire tracing. It looks like the PC, servos, etc. all take 120 VAC power from a 480 to 120 transformer. It sure looks to me like the kid can buy a PC, install the software. then remove these two wires and connect to a wall outlet. I think he will be able to jog the machine around at this point. Does anyone know for sure???

OK, his job for the week is install all power wiring, get a PC and install software.

My job is read all the manuals and try to learn all I can about starting up a water jet.

By chance, if anyone out there is expert on this machine, I'd sure like to hear from you. Neither of us have done more than just watch one run.