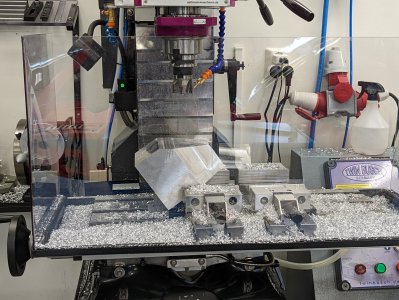

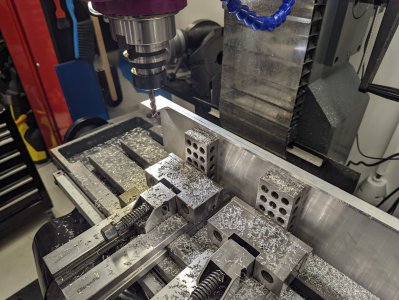

When doing larger jobs on the mill I got chips and coolant all over the place.

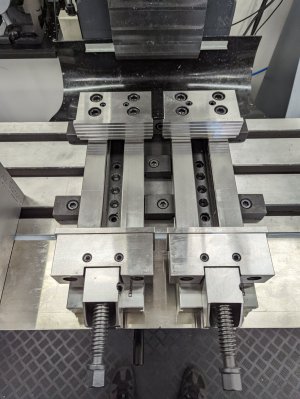

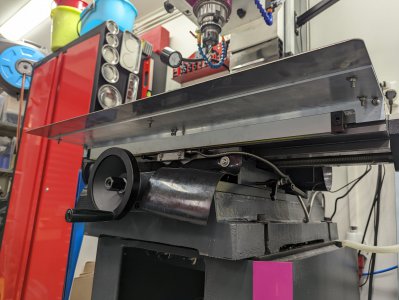

So I extended the front of the table 14 cm with a 2 mm stainless steel plate angled 90°.

Sealed the joint between the table and the place with some silicone.

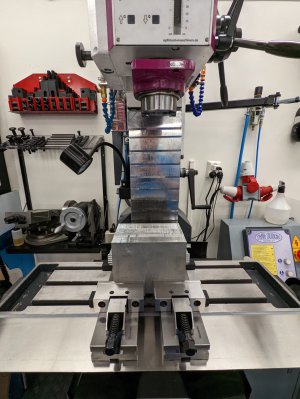

Then I built a chip guard out of some polycarbonate plastic that I carefully heated up and bent.

This is how it looks on the machine.

So I extended the front of the table 14 cm with a 2 mm stainless steel plate angled 90°.

Sealed the joint between the table and the place with some silicone.

Then I built a chip guard out of some polycarbonate plastic that I carefully heated up and bent.

This is how it looks on the machine.