- Joined

- Jan 25, 2015

- Messages

- 2,558

A little back story:

When I was instructor at the SAR school, I used to ask my students if it was better to be good or lucky. I’d get all sorts of answers, but my point was always to be aspire to be “good”, because lucky is something that may or may not be there. I always used to close that out with “I have to be good because I have no luck at all”.

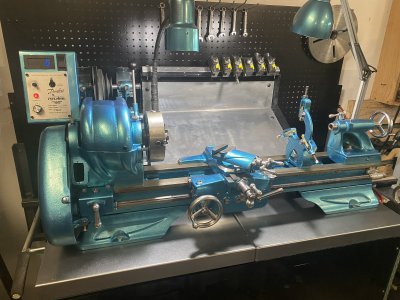

Well, the lathe burning out pots on me just proved that once again.

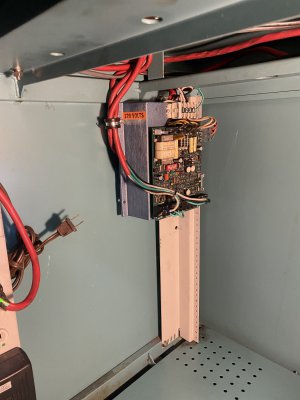

I pulled the entire schmozzle out of the kathe today and started tracing wires, testing electronics and verifying it all against the wiring/engineering drawings.

Turns out, even though I was meticulous (or so I thought) at labeling every single wire before I took it apart for painting, I somehow missed that I had three 6’s on the wire ends.

chasing it down, I had managed to hook one of the pots legs to the mains. Yep, that will smoke a few pots for sure.

So, I was not “good” when I labeled them, I was “unlucky” when I reconnected them and I was even more “unlucky” when I let the smoke out.

Lets hope my “unluckiness” doesn’t hold and the board is still good…

Can’t win for loosing….

When I was instructor at the SAR school, I used to ask my students if it was better to be good or lucky. I’d get all sorts of answers, but my point was always to be aspire to be “good”, because lucky is something that may or may not be there. I always used to close that out with “I have to be good because I have no luck at all”.

Well, the lathe burning out pots on me just proved that once again.

I pulled the entire schmozzle out of the kathe today and started tracing wires, testing electronics and verifying it all against the wiring/engineering drawings.

Turns out, even though I was meticulous (or so I thought) at labeling every single wire before I took it apart for painting, I somehow missed that I had three 6’s on the wire ends.

chasing it down, I had managed to hook one of the pots legs to the mains. Yep, that will smoke a few pots for sure.

So, I was not “good” when I labeled them, I was “unlucky” when I reconnected them and I was even more “unlucky” when I let the smoke out.

Lets hope my “unluckiness” doesn’t hold and the board is still good…

Can’t win for loosing….