-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

parting tool?

- Thread starter Firstgear

- Start date

anyone have a good suggestion for a parting tool? I have a PM 1440GS with BXA tool post.....

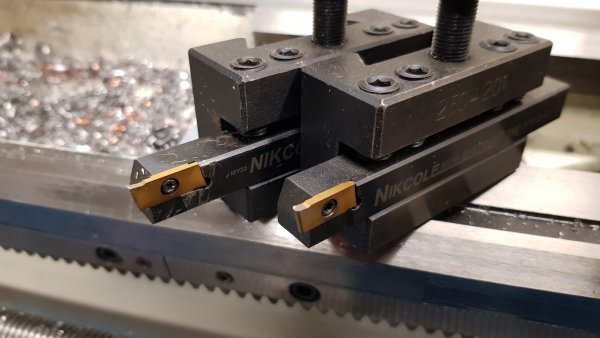

I made my holder so it would be stiffer. Here is how I did it

Sent from my iPhone using Tapatalk

- Joined

- Dec 2, 2012

- Messages

- 1,723

I have one like this, it's amazing.

SPB32-3 32mm Cut Off Blade with 25mm Blade Holder

I use it on a 13" lathe in a 2 way tool post. Steel and brass it loves, aluminum not so much, but the inserts arn't listed as good for aluminium so I guess thats why, I think a lot of WD40 or similar would make it ok on aluminuim perhaps.

Stuart

SPB32-3 32mm Cut Off Blade with 25mm Blade Holder

SPB32-3 32mm Cut Off Blade with 25mm Blade Holder and 10pcs ZQMX3N11-1E SP300 In | eBay

Find great deals for SPB32-3 32mm Cut Off Blade with 25mm Blade Holder and 10pcs ZQMX3N11-1E SP300 In. Shop with confidence on eBay!

www.ebay.co.uk

I use it on a 13" lathe in a 2 way tool post. Steel and brass it loves, aluminum not so much, but the inserts arn't listed as good for aluminium so I guess thats why, I think a lot of WD40 or similar would make it ok on aluminuim perhaps.

Stuart

- Joined

- Dec 26, 2015

- Messages

- 2,079

I work on a PM1340GT, and have about 10 different parting tools - from simple HSS blades to expensive indexable tools. Which tool I pick has a lot to do with the material I'm going to cut and how deeply, and how wide I can get away with. It's also extremely important that the tool is exactly on spindle centerline, and is precisely perpendicular to the CL of the spindle. The more rigid the setup the better - so get your compound back over the CL of the cross slide and lock everything down. Beyond that, over feeding the tool, and lack of continuous luberication are the next most likely culprets for parting failures. Unless I'm doing tapers or threading, I will replace the compound with my shop-made solid tool post which I has done wonders to improve parting off operations and surface finish in general. The solid tool post is a variant on what Robin Renzetti and Stefan Gotteswinter covered on their YouTube channels and my build is covered here: https://flic.kr/s/aHsm1cKjPB

For aluminum, I will often reach for a HSS blade in an Aloris BXA-71 blade holder. The cutoff blace is super easy to shapen on a bench grinder, and the #71 holder has a horizontal rather than inclined reference surface for the blade so you don't loose center height when the blade is repositioned or sharpened in the tool holder. I will often swap the HSS blade out for a cheap insert holder or brazed carbide blade for mild steel.

For more challenging metals (I do a lot of 316 SS), my favorite/go-to parting tool is the Seco Parting tool holder CFZR 0752802DRBJET.

This is it on MSC: https://www.mscdirect.com/product/details/51482339?rItem=51482339

This is the insert it takes on MSC: https://www.mscdirect.com/product/details/51487478?rItem=51487478

Keith Fenner clued me in on this parting tool, and although expensive, it has proven to be the most reliable for difficult materials. It does require a 3/4" holder, which Precision Matthews sells for BXA mounts (most BXA are limited to 1/2" or 5/8").

Hope this helps.

For aluminum, I will often reach for a HSS blade in an Aloris BXA-71 blade holder. The cutoff blace is super easy to shapen on a bench grinder, and the #71 holder has a horizontal rather than inclined reference surface for the blade so you don't loose center height when the blade is repositioned or sharpened in the tool holder. I will often swap the HSS blade out for a cheap insert holder or brazed carbide blade for mild steel.

For more challenging metals (I do a lot of 316 SS), my favorite/go-to parting tool is the Seco Parting tool holder CFZR 0752802DRBJET.

This is it on MSC: https://www.mscdirect.com/product/details/51482339?rItem=51482339

This is the insert it takes on MSC: https://www.mscdirect.com/product/details/51487478?rItem=51487478

Keith Fenner clued me in on this parting tool, and although expensive, it has proven to be the most reliable for difficult materials. It does require a 3/4" holder, which Precision Matthews sells for BXA mounts (most BXA are limited to 1/2" or 5/8").

Hope this helps.

- Joined

- Nov 27, 2012

- Messages

- 7,854

I'm not a big fan of the common GTN/GTL/GTR inserts for parting blades. I love my Manchester Separator & Nikcole Mini Systems parting & grooving tools. I use the old Manchester tools the most. Very sharp, nice groove on the center of the insert so they fold the chip to help evacuate easy, & they last forever. Parts Ti 6-4 like butter too. Manchester was bought out by Kennametal years ago but the Separator tools can still be purchased under the Kennametal & Widia brands.

My favorite parting tool is the bandsaw. I rarely use a parting blade. Whatever exceeds the capacity of my Manchester tools I use the bandsaw.

I rarely use a parting blade. Whatever exceeds the capacity of my Manchester tools I use the bandsaw.

My favorite parting tool is the bandsaw.

I use a .125” T shaped HSS tool and holder from Shars. I leave it about 1” out, I don’t adjust it for the part diameter. I part steel at 90 rpm, aluminum at 250. Both with the feed set at approx .010” / rev, so an actual feed of about .005” / rev. Lathe is a 1440GT.

I have parted 303, 304, 6061, 316, 416, 4140, brass, UHMW, and mystery metal, in diameters up to 2”. I always use power feed.

I have never had a single problem. I’m not an old hand, but I’ve made several hundred parting cuts, I’d estimate 300-500.

I sharpen the tool when it no longer feels quite as sharp, maybe 4 times now.

Perhaps my time is coming, but all the parting woes are a little mysterious to me.

I have parted 303, 304, 6061, 316, 416, 4140, brass, UHMW, and mystery metal, in diameters up to 2”. I always use power feed.

I have never had a single problem. I’m not an old hand, but I’ve made several hundred parting cuts, I’d estimate 300-500.

I sharpen the tool when it no longer feels quite as sharp, maybe 4 times now.

Perhaps my time is coming, but all the parting woes are a little mysterious to me.

I used many Iscar insert parting tools in the past with no problems .

The tool I made was a copy of the blocks available I felt that if it was one piece mounted to the BXA that would increase the strength of the cut off tool.

I use the GTN type inserts for cut off and it works well for me.

Sent from my iPhone using Tapatalk

I use a .125” T shaped HSS tool and holder from Shars. I leave it about 1” out, I don’t adjust it for the part diameter. ...

... I’m not an old hand, but I’ve made several hundred parting cuts, I’d estimate 300-500.

I sharpen the tool when it no longer feels quite as sharp, maybe 4 times now.

Perhaps my time is coming, but all the parting woes are a little mysterious to me.

Everything you said that I quoted above mirrors my experience to a T. I have experienced a couple issues but believe it's because I fed too fast. The part I made bold is what I'm waiting for. LOL. I'm looking at all the tools people have posted just see what other options are out there since I've only used HSS blades.