- Joined

- Oct 28, 2020

- Messages

- 528

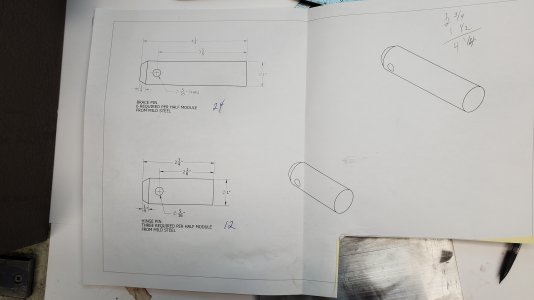

This weekend in my humble basement shop I made up a wack of simple pins. These are what I would call structural pins,they get welded to C-channel. The dimensions in the drawing are more "guidelines" or "suggestions", nothing precision required. More an exercise in persistence and efficiency rather than precision.

Not exciting but it got me off the couch and I made some pocket money.

- cut to length

- face one end (so it sits nice for welding)

- heavy chamfer on other end

- cross drill

- chamfer both sides of cross drilled hole

Not exciting but it got me off the couch and I made some pocket money.