http://pounceatron.dreamhosters.com/fay-scott/shop/index.html

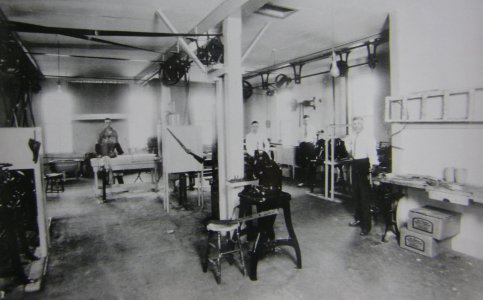

I thought this set of photos was fascinating. First few are of the admin office then the workshop.

Bill

I thought this set of photos was fascinating. First few are of the admin office then the workshop.

Bill

Last edited: