- Joined

- Sep 2, 2013

- Messages

- 5,090

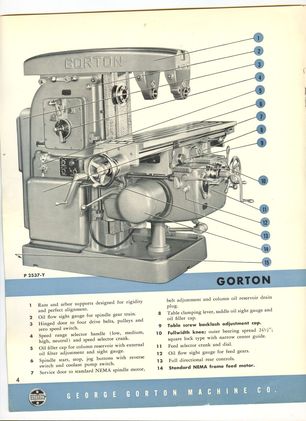

Spending the night at my sons place, and heading down to Colorado Springs area in the morning to load up 8000# of loveliness. 600 miles round trip, but I've been looking for something like this for a while, and the price was right. will post some pics when I get her home. Mike

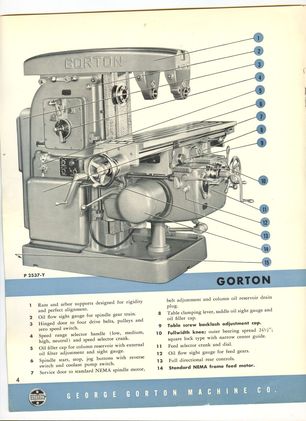

Same mill, but the one I'm getting also has the vertical head.

Same mill, but the one I'm getting also has the vertical head.