- Joined

- May 20, 2013

- Messages

- 390

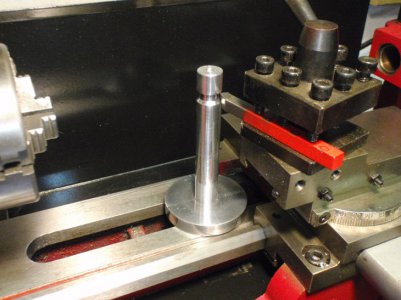

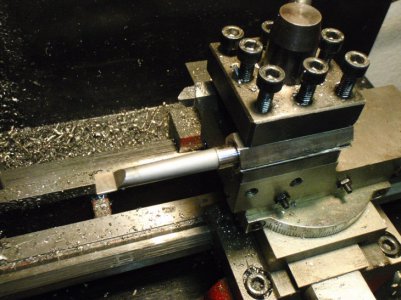

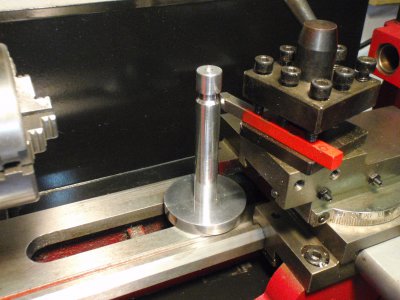

Wholesale Tools has three different QC tool posts for the mini lathe, the least expensive is only $40. I plan on ordering one - don't know if anyone else on here has used one or not, but they look like they should work fine. Here is the one I'm looking at. http://www.wttool.com/index/page/pr...l+Post+Set+(WT)&update_continue_shopping=true

It thas been a low priority since for me since I have a Harrison L6 lathe as well as the mini lathe.

Dan

It thas been a low priority since for me since I have a Harrison L6 lathe as well as the mini lathe.

Dan