- Joined

- Jul 26, 2011

- Messages

- 4,142

I have a silversmith friend who needs a pump drill,so I started making her one. I swear,I used to turn those out in NO time,complete with all kinds of fancy moldings. Now,even with a much better lathe,it just takes me forever.

The same with making a guitar. I was working nearly ALL by hand back in my younger days,and could make a guitar in 2 weeks. Now it takes me forever!

Years ago I made an accurate form tool for cutting the rims out,and I still am using it here. I might have ground most of the curve out of the tool,and finished it off with a carbide rotary file,then cleaning up with slip stones. I can't really remember.

It is easy to "piece" the round shape of the rim out by positioning the form tool by eye,after the initial cut is made.

These seem to be all of the pictures I have for now. The tapered thread for slightly closing the 1/8" built in "collet" on the 1/8" shank spade bits I also will make,is done by use of a 1/16" pipe die,27 TPI. The collet will be slit to flex enough to grasp the bits.

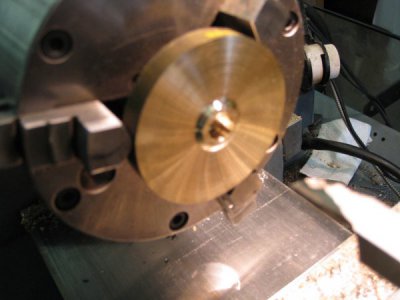

The flywheel starts out faced off true,and a 1/2" hole bored through it,which TIGHTLY accepts a 1/2" bar of mild steel that has been taper turned into the shaft of the bow drill. I put a little red Loctite on the press fit,to get it solid enough to stand turning the round rim and other bits true ON THE SHAFT,to ensure smooth,true running.

This is in my HLVH lathe.

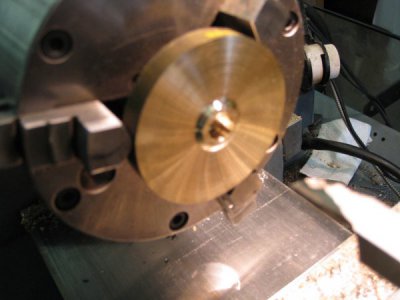

The little groove I am cutting into the flywheel will be where I'll stamp my maker's name. It just fits the size of the letter stamps,and helps to get them nice and straight. Sometimes I'll cut a round groove,stamp the name,then eliminate the groove by turning the metal down some more,leaving only the name magically stamped perfectly aligned. DIRTY TRICKS PAY!! I also like to take a light cut over stamped letters when I stamp lathe turned objects,removing the pooched up metal that surrounds the impressions. I remember where the cross slide was set when I cut the depth of the cut before. I advance the cross slide to that same depth,so as to not cut into the actual letters. It looks so cheap when you see a rifle or other object where they just rolled the name on,and left the raised metal around the letters.

I also like to take a light cut over stamped letters when I stamp lathe turned objects,removing the pooched up metal that surrounds the impressions. I remember where the cross slide was set when I cut the depth of the cut before. I advance the cross slide to that same depth,so as to not cut into the actual letters. It looks so cheap when you see a rifle or other object where they just rolled the name on,and left the raised metal around the letters.

Now that I shake so much,I have to resort to little tricks to get things like letters stamped straight. Some use the tape from labeling machines to rest stamps on. I haven't tried that. But,I learned from a great master engraver to draw a mark with a sharp point with a straight edge, Then,slide the stamp down to the line till you feel it "click in". Then,bring the stamp vertical without shifting its position,and strike it. Then,without removing the stamp,rock it a bit and stamp all 4 "corners of the stamp to make sure you got the full impression. The stamps have to have crisp edges to make this work. Sand and polish off the scratched line afterwards. This is something I encourage all to practice in order to give your projects the neat finishiung touches it needs to be perfect.

I have a few other secrets to make neat stamping. If you don't get it neat,it ruins the whole job.

I have made several molding turning form tools. The ogee seen near the center of the flywheel was made with one of these,made from a 3/16" HSS lathe tool.

The same with making a guitar. I was working nearly ALL by hand back in my younger days,and could make a guitar in 2 weeks. Now it takes me forever!

Years ago I made an accurate form tool for cutting the rims out,and I still am using it here. I might have ground most of the curve out of the tool,and finished it off with a carbide rotary file,then cleaning up with slip stones. I can't really remember.

It is easy to "piece" the round shape of the rim out by positioning the form tool by eye,after the initial cut is made.

These seem to be all of the pictures I have for now. The tapered thread for slightly closing the 1/8" built in "collet" on the 1/8" shank spade bits I also will make,is done by use of a 1/16" pipe die,27 TPI. The collet will be slit to flex enough to grasp the bits.

The flywheel starts out faced off true,and a 1/2" hole bored through it,which TIGHTLY accepts a 1/2" bar of mild steel that has been taper turned into the shaft of the bow drill. I put a little red Loctite on the press fit,to get it solid enough to stand turning the round rim and other bits true ON THE SHAFT,to ensure smooth,true running.

This is in my HLVH lathe.

The little groove I am cutting into the flywheel will be where I'll stamp my maker's name. It just fits the size of the letter stamps,and helps to get them nice and straight. Sometimes I'll cut a round groove,stamp the name,then eliminate the groove by turning the metal down some more,leaving only the name magically stamped perfectly aligned. DIRTY TRICKS PAY!!

Now that I shake so much,I have to resort to little tricks to get things like letters stamped straight. Some use the tape from labeling machines to rest stamps on. I haven't tried that. But,I learned from a great master engraver to draw a mark with a sharp point with a straight edge, Then,slide the stamp down to the line till you feel it "click in". Then,bring the stamp vertical without shifting its position,and strike it. Then,without removing the stamp,rock it a bit and stamp all 4 "corners of the stamp to make sure you got the full impression. The stamps have to have crisp edges to make this work. Sand and polish off the scratched line afterwards. This is something I encourage all to practice in order to give your projects the neat finishiung touches it needs to be perfect.

I have a few other secrets to make neat stamping. If you don't get it neat,it ruins the whole job.

I have made several molding turning form tools. The ogee seen near the center of the flywheel was made with one of these,made from a 3/16" HSS lathe tool.

Last edited: